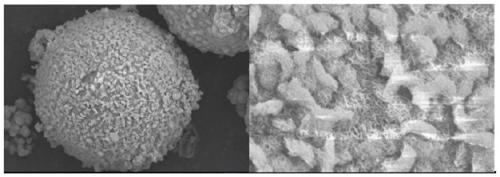

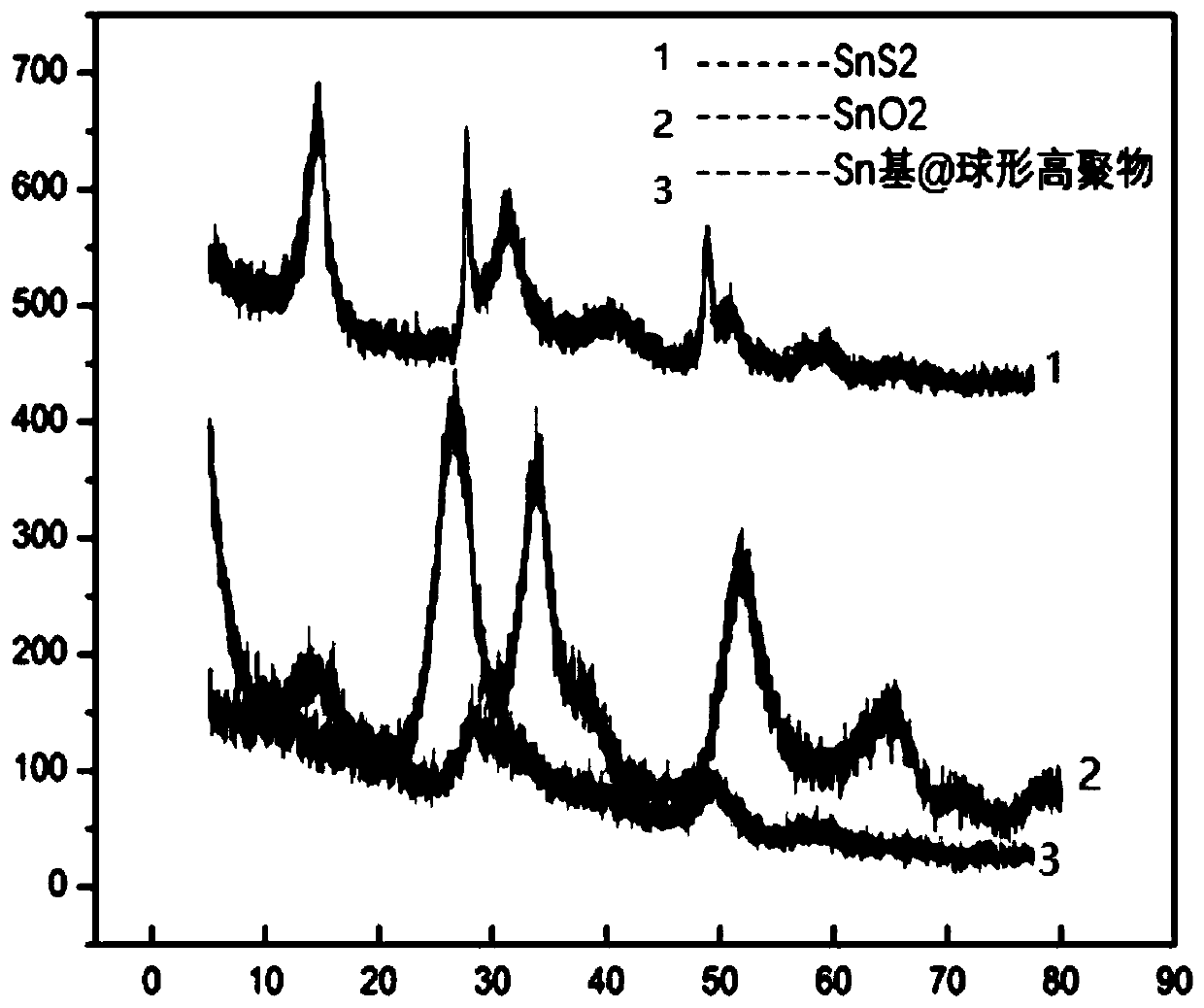

Transition Sn-based heterojunction material@spherical high polymer, and preparation method and application thereof

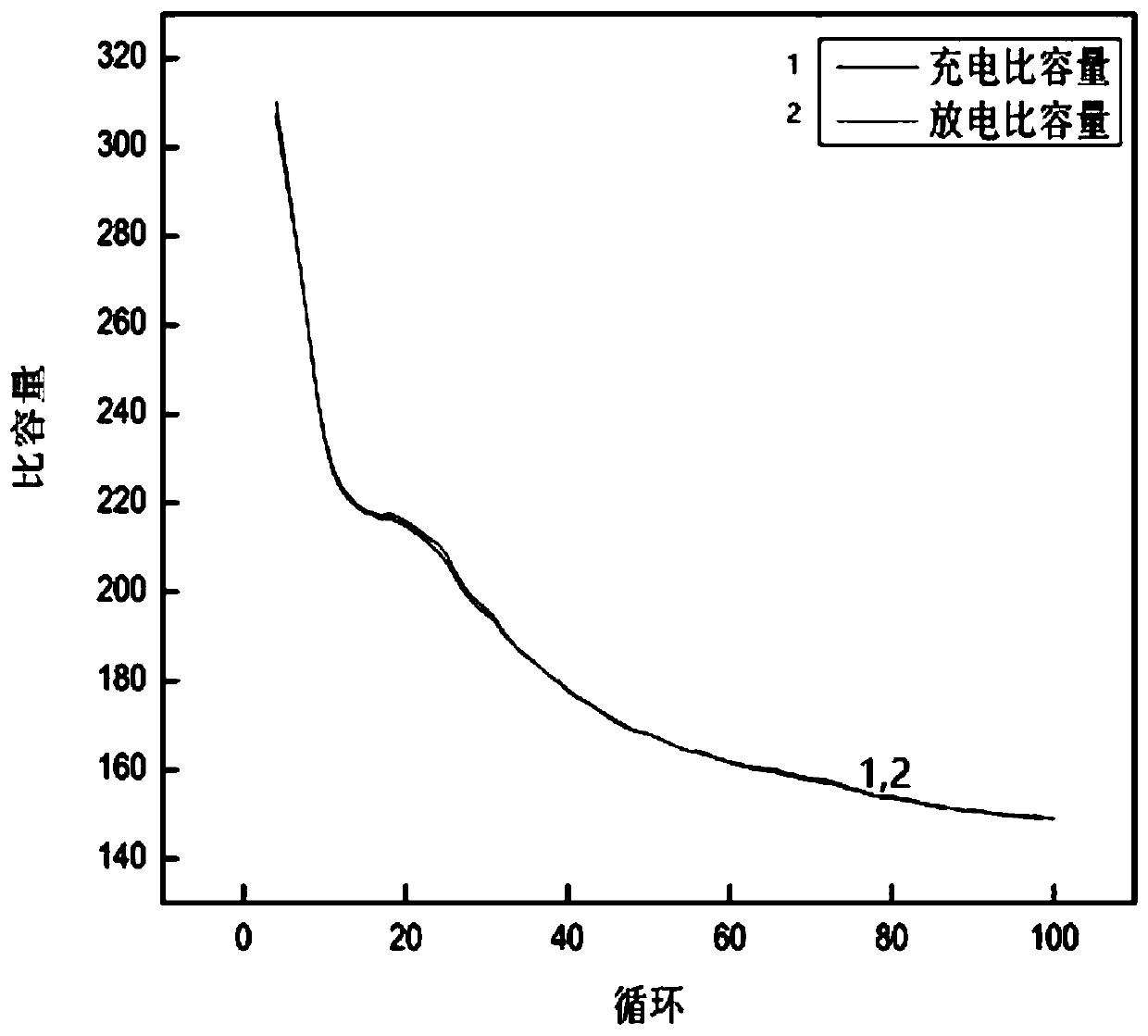

A polymer and heterojunction technology, applied in structural parts, active material electrodes, electrical components, etc., can solve the problems of insufficient capacity requirements and cycle performance, high cost, save heat loss, strong crystallinity, and reaction rate. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Disperse 2.5 g of glucose hydrothermally obtained at 180° C. in ethanol, stir first for 3 hours, and then ultrasonicate for 1 hour to make it uniformly dispersed.

[0027] 2) above-mentioned solution, under the action of magnetic stirring, add the solid powder of tin tetrachloride pentahydrate of 0.25g, magnetic stirring 6 hours, be denoted as solution A;

[0028] 3) The above solution A is kept in a state of stirring, and 0.40 g of thioacetamide is added therein, which is denoted as solution B;

[0029] 4) The other magnetic stirrer was adjusted to the heating state, and the temperature was raised to 55 degrees Celsius and maintained.

[0030] 5) Put solution B on a magnetic stirrer with a set temperature, and heat until the ethanol is basically evaporated to dryness, add 50 ml of ethanol, and heat for 20 min, which is recorded as solution C.

[0031] 6) After the reaction is over, collect solution C, wash it by centrifugation with deionized water and anhydrous eth...

Embodiment 2

[0034] 1) Disperse 2.5 g of glucose hydrothermally obtained at 180° C. in ethanol, stir first for 3 hours, and then ultrasonicate for 1 hour to make it uniformly dispersed.

[0035] 2) above-mentioned solution, under the action of magnetic stirring, add the solid powder of tin tetrachloride pentahydrate of 0.35g, magnetic stirring 6 hours, be recorded as solution A;

[0036] 3) The above solution A is kept in a state of stirring, and 0.40 g of thioacetamide is added therein, which is denoted as solution B;

[0037] 4) The other magnetic stirrer was adjusted to the heating state, and the temperature was raised to 55°C and maintained.

[0038] 5) Put solution B on a magnetic stirrer with a set temperature, and heat until the ethanol is basically evaporated to dryness, add 50 ml of ethanol, and heat for 20 min, which is recorded as solution C.

[0039] 6) After the reaction is over, collect solution C, wash it by centrifugation with deionized water and anhydrous ethanol, set the...

Embodiment 3

[0042] 1) Disperse 2.5 g of glucose hydrothermally obtained at 180° C. in ethanol, stir first for 3 hours, and then ultrasonicate for 1 hour to make it uniformly dispersed.

[0043] 2) above-mentioned solution, under the action of magnetic stirring, add the solid powder of tin tetrachloride pentahydrate of 0.35g, magnetic stirring 6 hours, be recorded as solution A;

[0044] 3) The above solution A is kept in a state of stirring, and 0.40 g of thioacetamide is added therein, which is denoted as solution B;

[0045] 4) The other magnetic stirrer was adjusted to the heating state, and the temperature was raised to 75°C and maintained.

[0046] 5) Put solution B on a magnetic stirrer with a set temperature, heat until the ethanol is basically evaporated to dryness, add 100 ml of ethanol, heat for another 20 min, and denote it as solution C.

[0047] 6) After the reaction is over, collect solution C, wash it by centrifugation with deionized water and anhydrous ethanol, set the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com