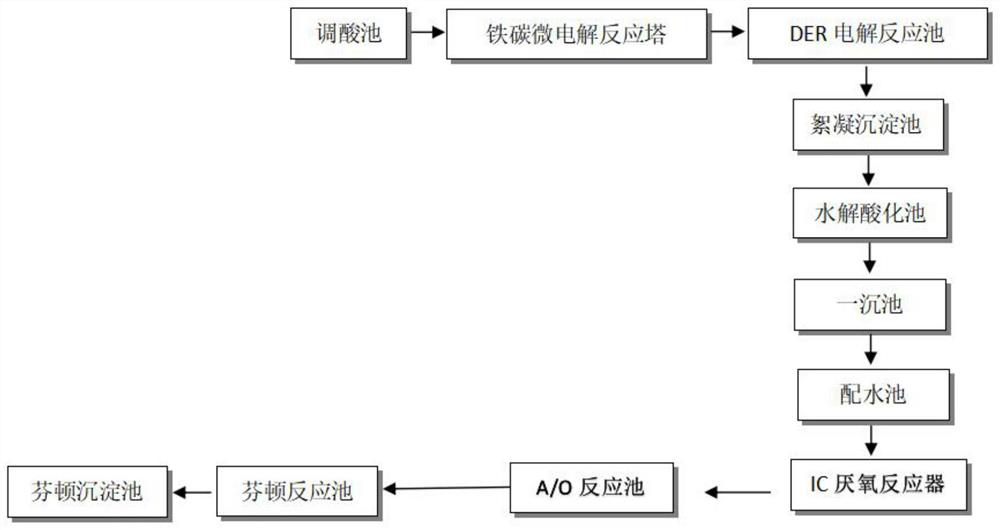

Wastewater treatment process

A wastewater treatment and process technology, applied in the field of electrolysis process, can solve the problem of low rising flow rate in the fine treatment area, and achieve the effect of low operating cost, low investment cost and good coagulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

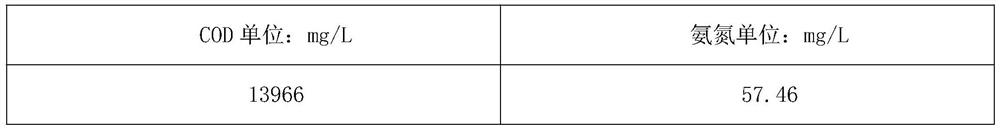

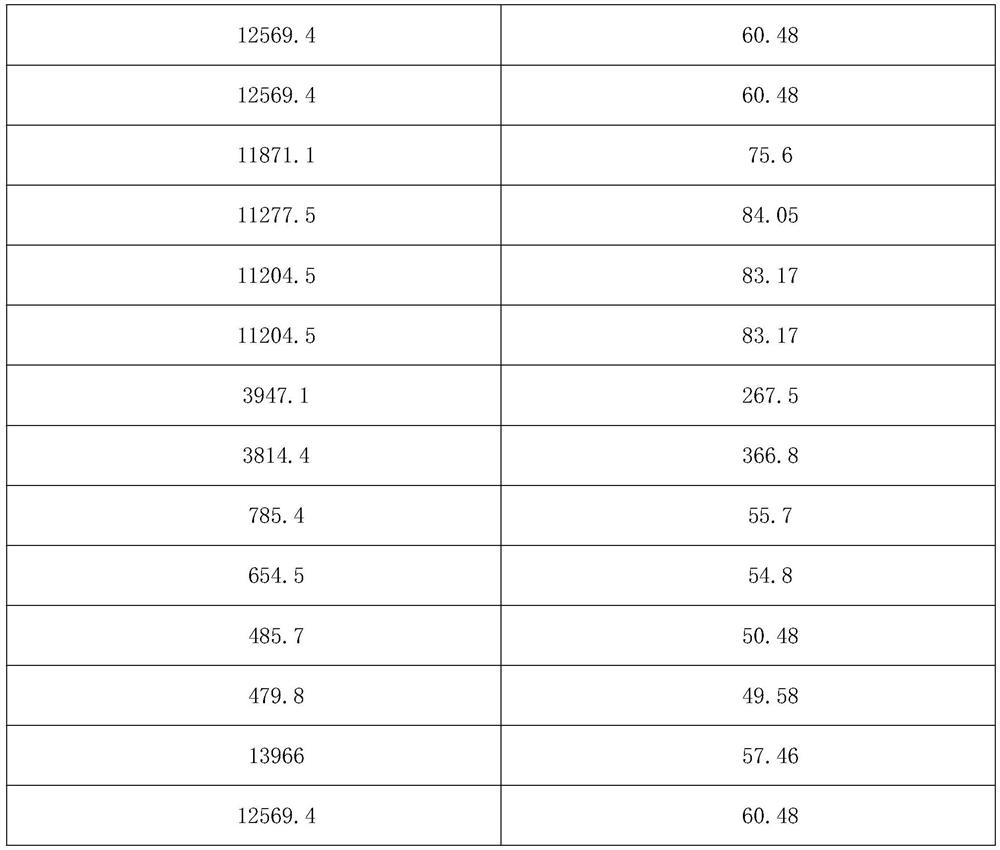

Embodiment 1

[0032] A wastewater treatment process, comprising the steps of:

[0033] S1: Pump the wastewater into the acid adjustment tank, use the aeration device to aerate the wastewater in the neutralization tank, and add acid to the tank at the same time to adjust the pH value of the wastewater to 3-4;

[0034] S2: The waste water is pumped into the micro-electrolysis reactor, and the waste water in the tower is subjected to air aeration treatment with an aeration device, and stays for 1-2 hours;

[0035] S3: The wastewater flows into the neutralization tank by itself, and the wastewater in the tower is aerated with air by the aeration device, and at the same time, alkali is added to the tank to adjust the pH value of the wastewater to 6-8;

[0036] S4: The waste water flows to the DER electrolysis reaction tank by itself, adjust the current of the electrolysis equipment at 10-1000A, control the voltage at 1-30V, and use the aeration device to aerate the electrolysis reaction tank wit...

Embodiment 2

[0050] A wastewater treatment process, comprising the steps of:

[0051] S1: Pump the wastewater into the acid adjustment tank, use the aeration device to aerate the wastewater in the neutralization tank, and add acid to the tank at the same time to adjust the pH value of the wastewater to 1-2;

[0052] S2: The waste water is pumped into the micro-electrolysis reactor, and the waste water in the tower is subjected to air aeration treatment with an aeration device, and stays for 1-2 hours;

[0053] S3: The wastewater flows into the neutralization tank by itself, and the wastewater in the tower is aerated with air by the aeration device, and at the same time, alkali is added to the tank to adjust the pH value of the wastewater to 6-8;

[0054] S4: The waste water flows to the DER electrolysis reaction tank by itself, adjust the current of the electrolysis equipment at 10-1000A, control the voltage at 1-30V, and use the aeration device to aerate the electrolysis reaction tank wit...

Embodiment 3

[0069] A wastewater treatment process, comprising the steps of:

[0070] S1: Pump the wastewater into the acid adjustment tank, use the aeration device to aerate the wastewater in the neutralization tank, and add acid to the tank at the same time to adjust the pH value of the wastewater to 5-6;

[0071] S2: The waste water is pumped into the micro-electrolysis reactor, and the waste water in the tower is subjected to air aeration treatment with an aeration device, and stays for 1-2 hours;

[0072] S3: The wastewater flows into the neutralization tank by itself, and the wastewater in the tower is aerated with air by the aeration device, and at the same time, alkali is added to the tank to adjust the pH value of the wastewater to 6-8;

[0073] S4: The waste water flows to the DER electrolysis reaction tank by itself, adjust the current of the electrolysis equipment at 10-1000A, control the voltage at 1-30V, and use the aeration device to aerate the electrolysis reaction tank wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com