Caliper cover assembly and production method thereof

A caliper cover and caliper technology, applied in the direction of brake parts, brake components, gear shifting mechanisms, etc., can solve the problems of firmness and safety crossover of the caliper cover, and achieve good installation adaptability, not easy to break, and firm structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] The embodiment provides a method for producing a caliper cover assembly, comprising the following steps:

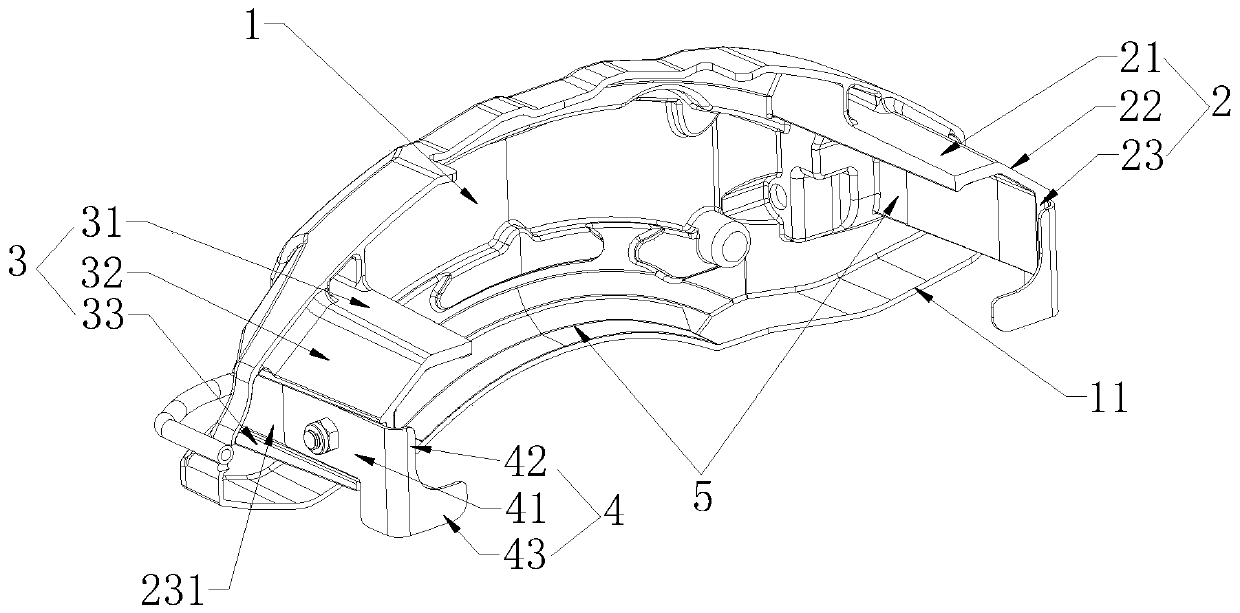

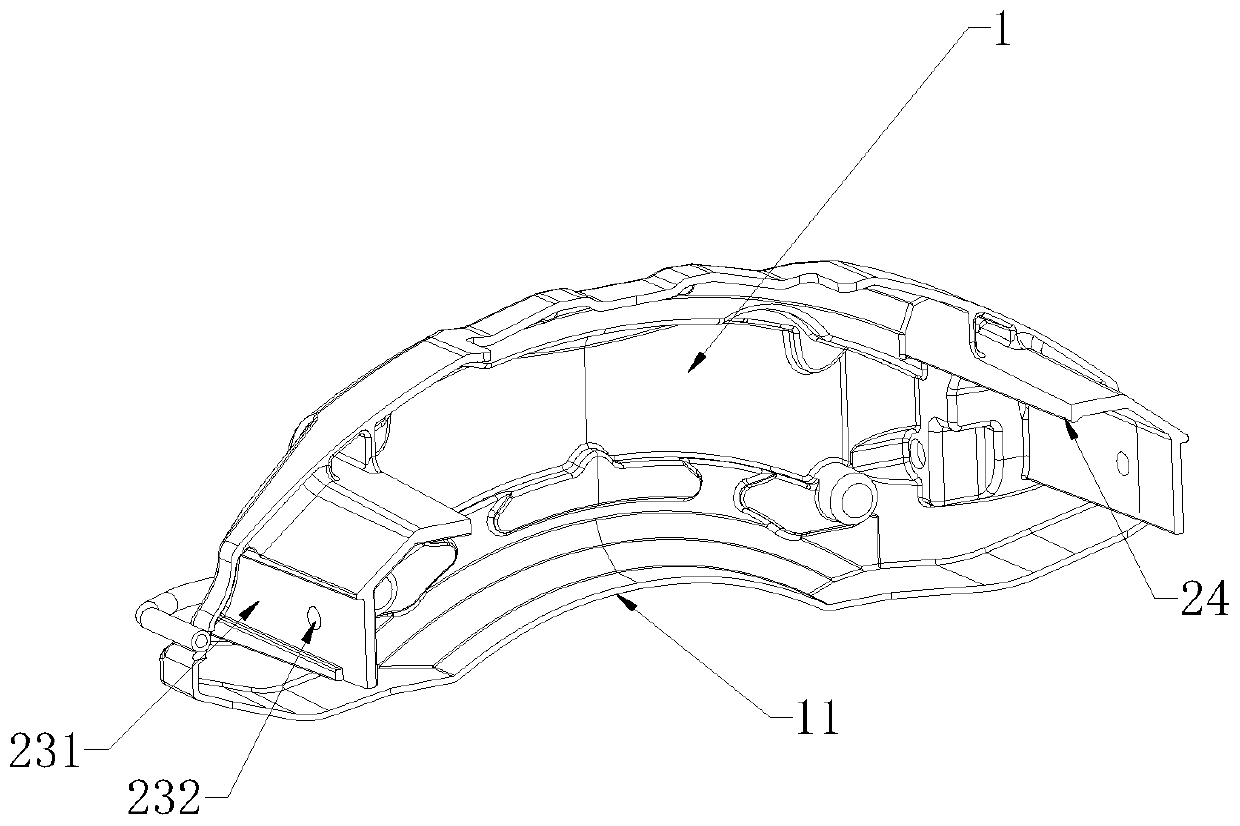

[0041] Carry out laser 3D copying of the brake caliper to obtain the shape parameters of the brake caliper, and obtain the shape parameters of the caliper cover body 1, the first bracket 2, the second bracket 3 and the buckle 4 according to the shape parameters of the brake caliper;

[0042] According to the shape parameters, the caliper cover body 1, the first bracket 2 and the second bracket 3 are integrally formed, and are produced by casting, extrusion and oxidation processes;

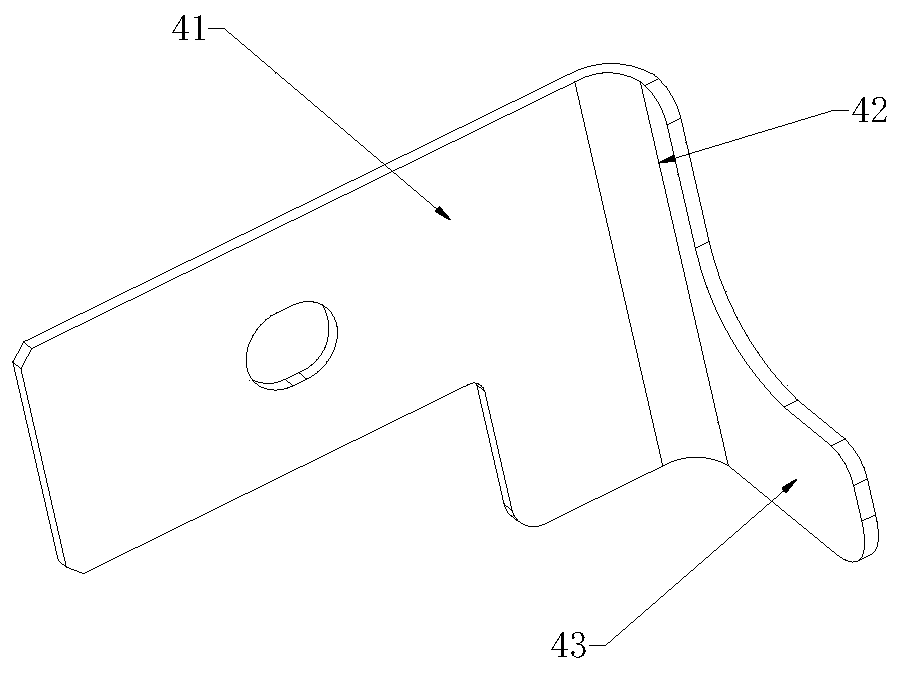

[0043] Process two buckles 4 according to the shape parameters;

[0044] Install heat-conducting silica gel 5 on the caliper cover body 1, the first bracket 2 and the second bracket 3 respectively;

[0045] The buckle 4 is fixed to the first bracket 2 and the second bracket 3 by bolts.

[0046] Since the caliper cover assembly is designed based on the shape parameters obtained by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com