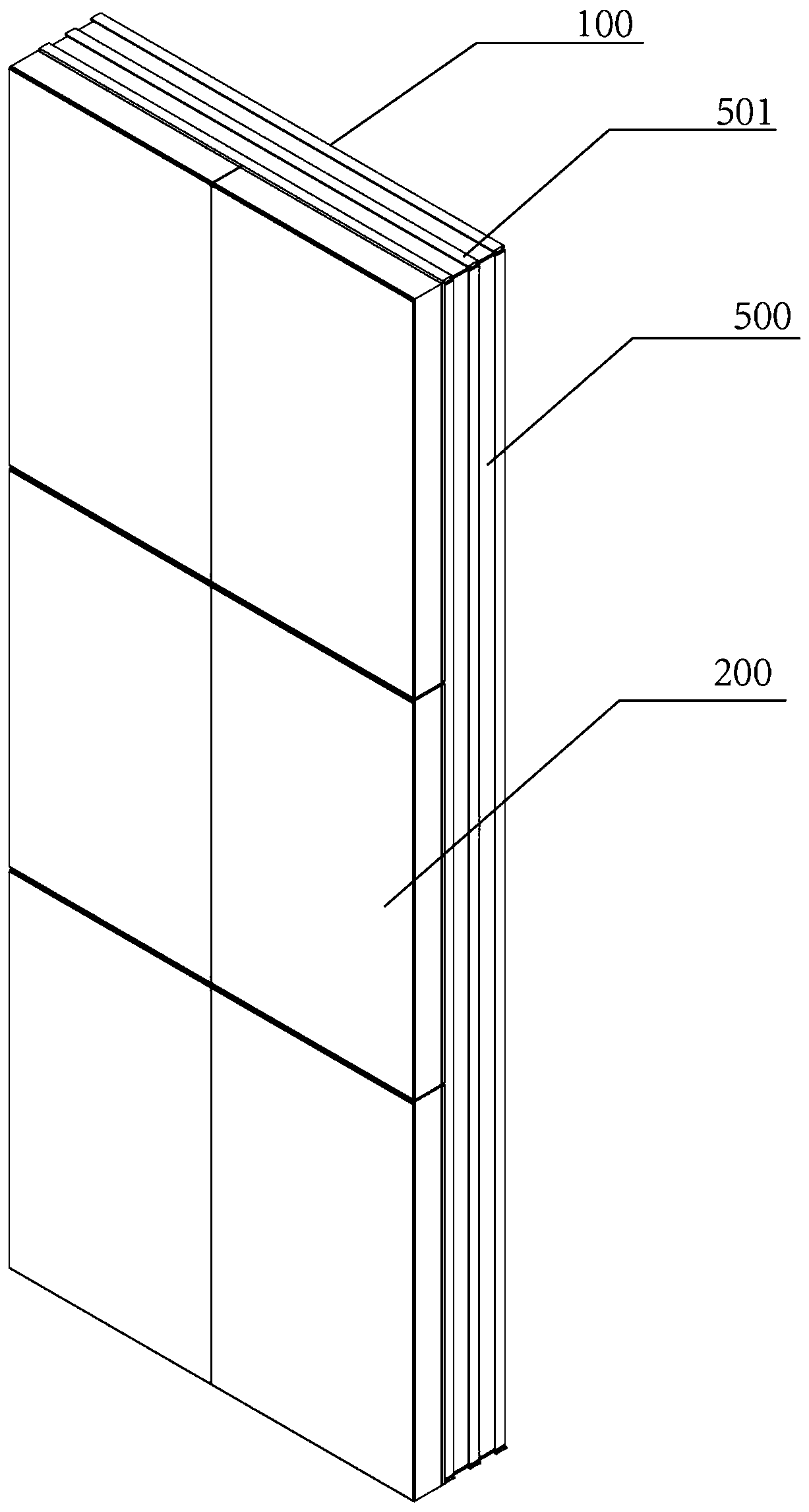

Light outer wall hanging plate assembly

A technology for external walls and sidings, which is applied to building components, building reinforcements, structural elements, etc., and can solve problems such as cumbersome processes, increased installation difficulties, and heavy weight of concrete sidings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

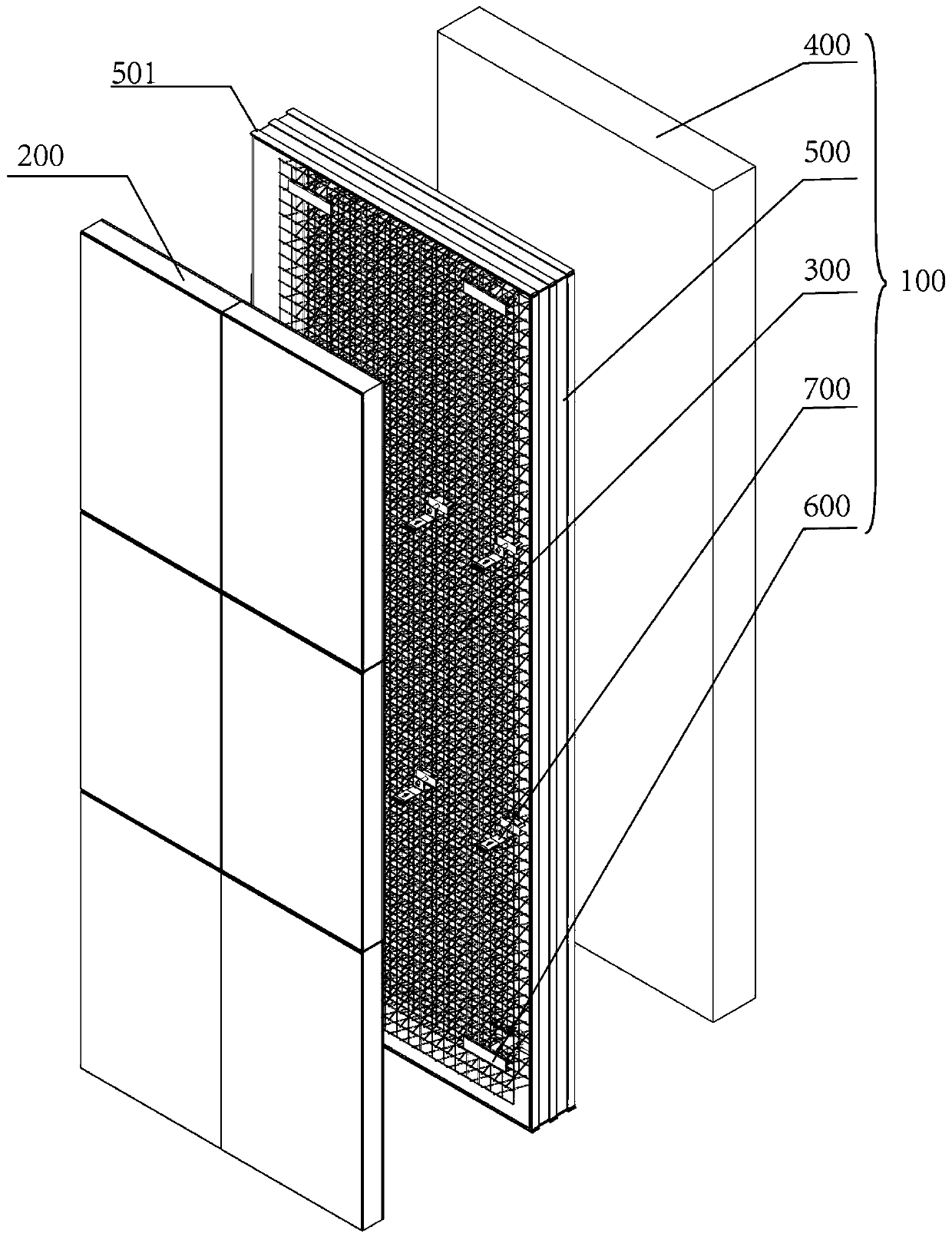

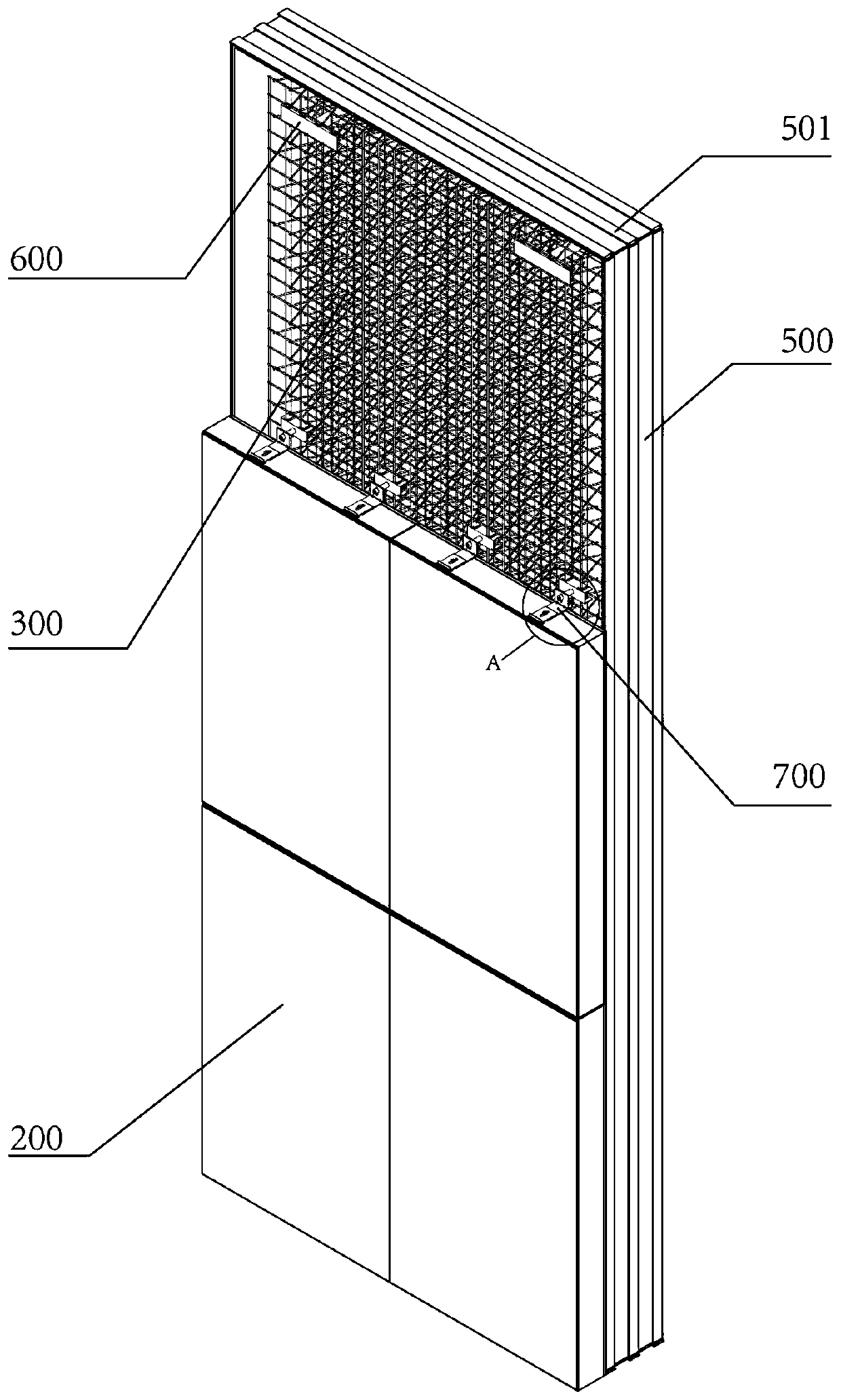

[0051] The present invention solves the problems of the heavy weight of the concrete siding in the prior art, and the cumbersome construction process such as hoisting, which makes installation difficult, and solves the problem that the cost of mold opening is increased due to the use of molds in the production of the external wall siding in the prior art. The problem of cumbersome process. It avoids the need to make a finishing layer or other thermal insulation measures on the outside after installation, thereby increasing the weight of the external wall hanging board and increasing the difficulty of installation, and provides a lightweight external wall hanging board assembly.

[0052] In order to further explain the technical means and effects of the present invention to achieve the purpose of the predetermined invention embodiment, the following is a light-weight exterior wall hanging panel assembly proposed according to the embodiment of the present invention in conjunction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com