Novel heightening expanding method for one-time constructed dam ultra-fine tailings pond through midline method

A technology for tailings storage and ultra-fine particles, which is applied in the field of heightening and expansion of ultra-fine tailings storage, which can solve the problems of low mechanical strength, long consolidation time, and high safety risks of ultra-fine particle tailings dam construction, etc. Achieve the effects of facilitating large-scale mechanized construction, prolonging the service life of production, and saving investment in building warehouses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to better describe the present invention, the new method of heightening and expanding the capacity of the superfine tailings reservoir for one-time dam construction in the present invention will be further described in detail below in conjunction with the accompanying drawings.

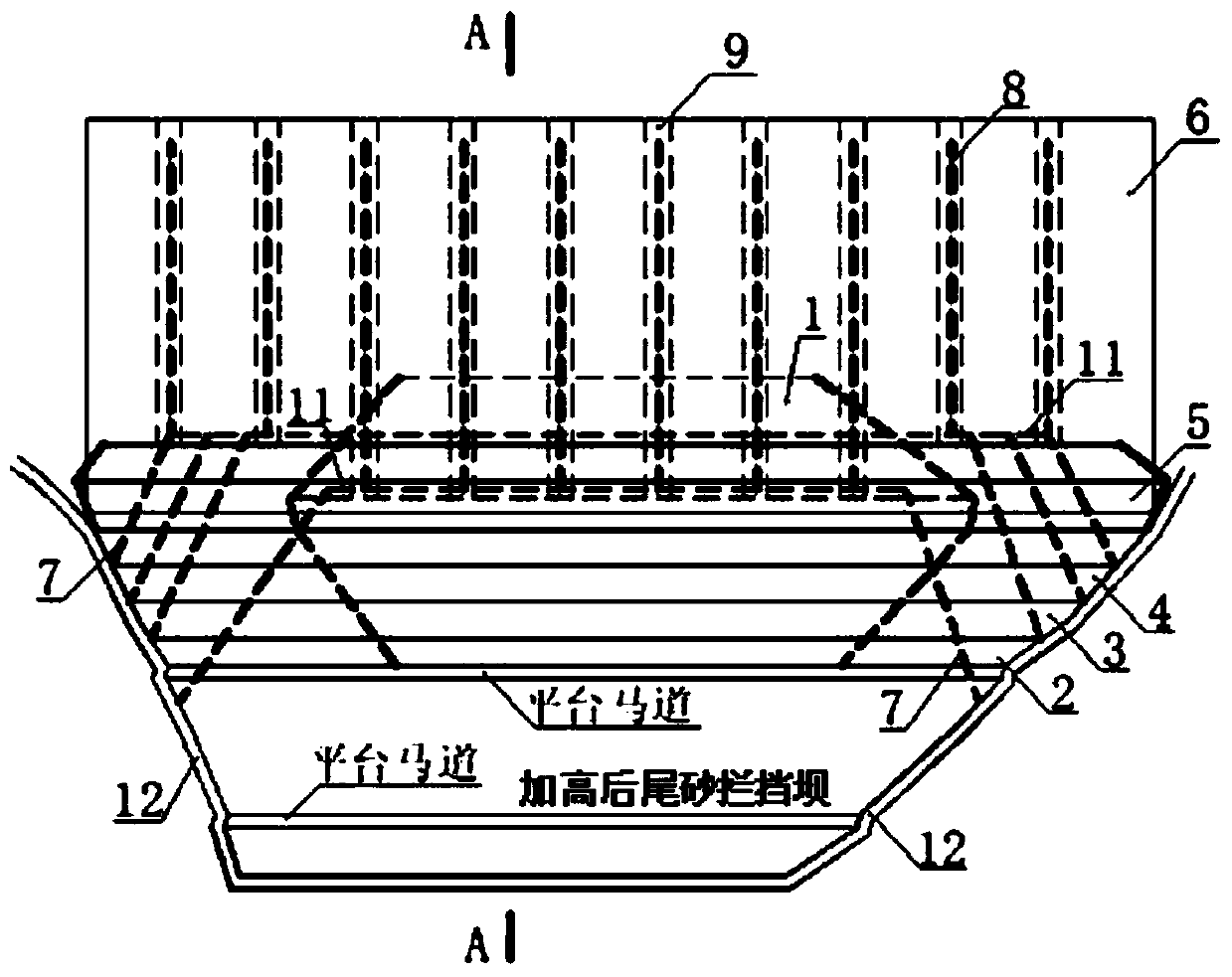

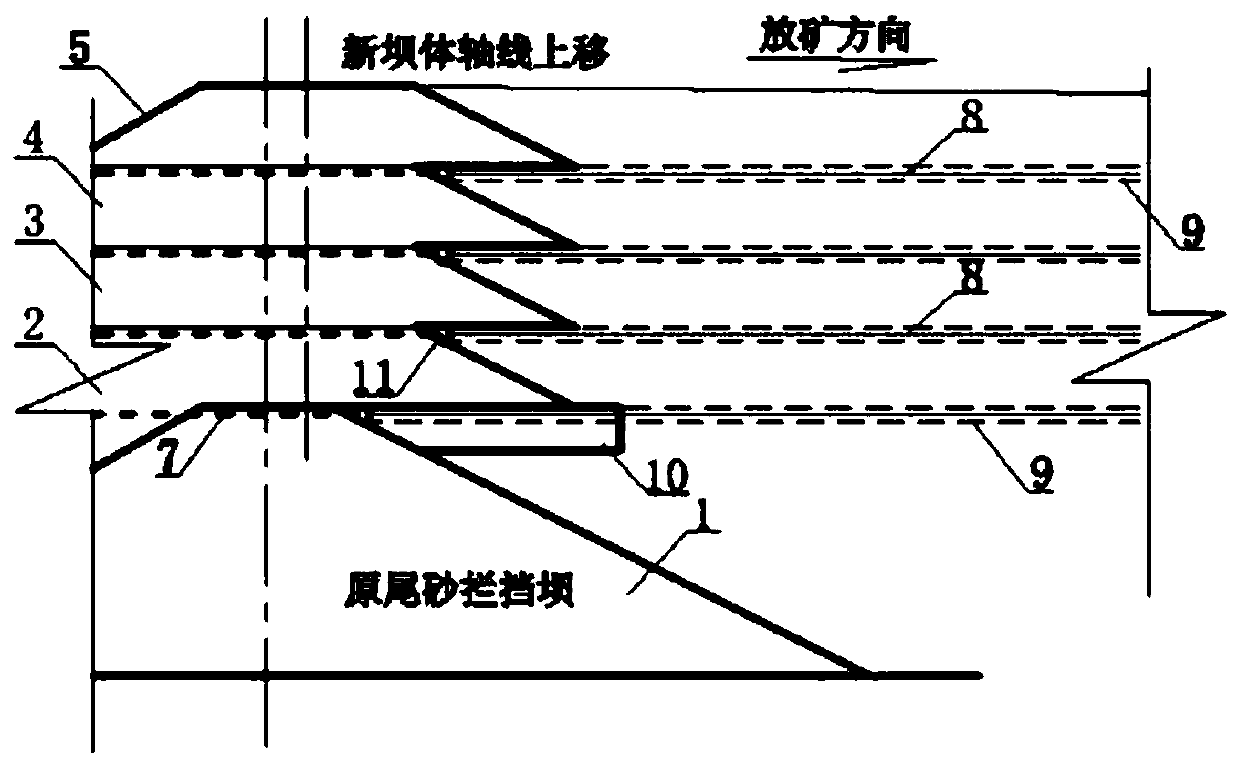

[0034] Depend on figure 1 The superfine grain tailings reservoir of the present invention shown in one-time dam construction adopts the new method plane layout schematic diagram of heightening and expansion of the midline method and combines figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that the ultra-fine tailings reservoir of the present invention's one-time dam construction adopts the new method of heightening and expanding the centerline method, which contains the original tailings retaining dam 1 and the abutment intercepting flood ditch 12, and the original tailings retaining dam 1 is one time The roller compacted earth-rock retaining dam that is built in a perma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com