Method for in-situ reinforcement of performance of paper-based material by aramid nanofibers

A technology of nanofiber and aramid fiber, which is applied in the direction of fiber raw material processing, reinforcing agent addition, non-fiber pulp addition, etc. It can solve the problems of nanofiber component loss, large paper web moisture, and increase production cost, and achieve nanofiber High retention rate, improved surface smoothness, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

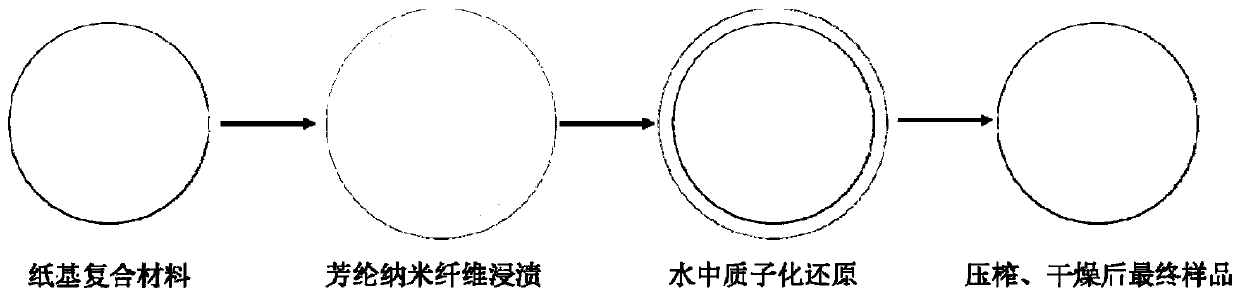

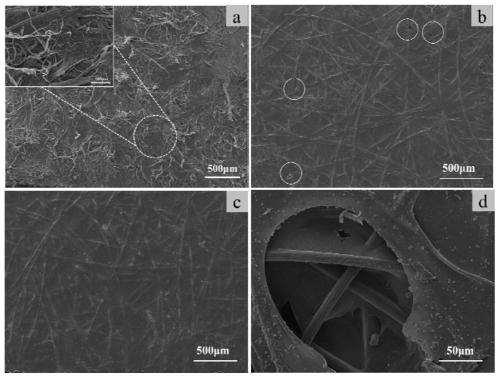

[0033] A method for in-situ performance enhancement of paper-based materials by aramid nanofibers in this embodiment, the specific preparation steps are as follows:

[0034] (1) Preparation of paper-based materials: The meta-aramid fiber paper-based composite material is prepared by traditional wet forming, and the ratio of meta-aramid fibrids to meta-aramid chopped fibers is 1:1;

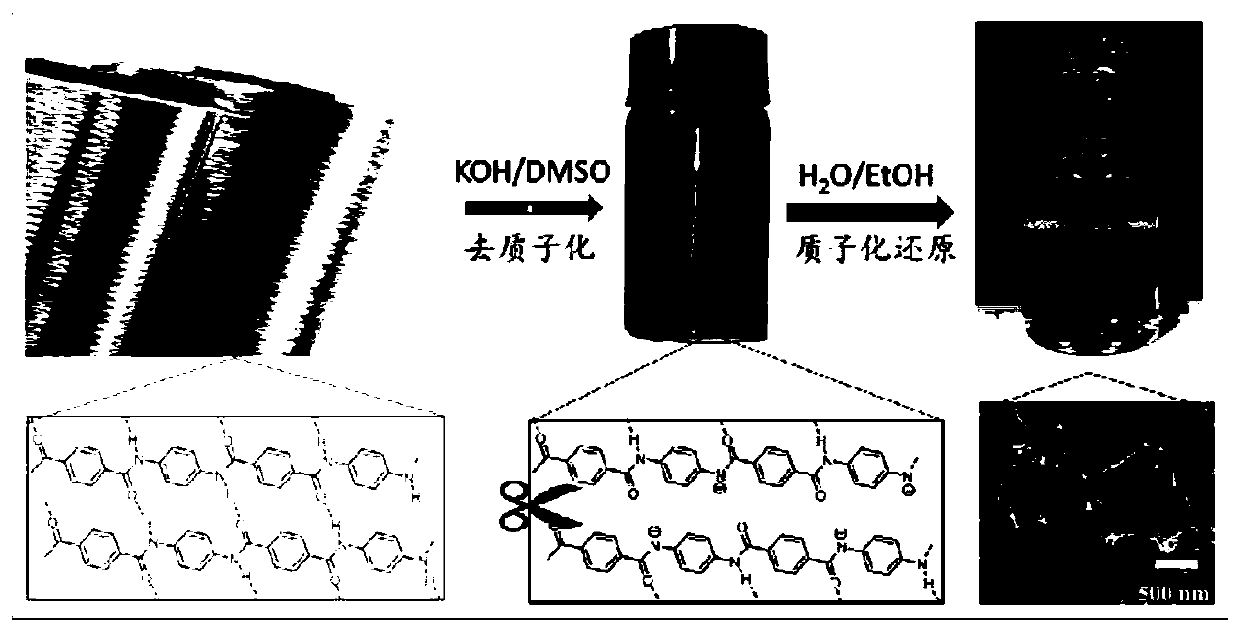

[0035] (2) Use DMSO, KOH and H for para-aramid chopped fibers 2 O is dissolved into the aramid fiber nanofiber solution whose mass concentration is 0.25%;

[0036] (3) Immerse the meta-aramid fiber paper-based composite material prepared in step (1) in the aramid nanofiber solution obtained in step (2); when the meta-aramid fiber paper-based composite material is completely After soaking, wait for 20s to make it fully absorbed;

[0037] (4) Transfer the meta-aramid fiber paper-based composite material impregnated in step (3) to water for soaking, and the protonation reduction time is about 24 hou...

Embodiment 2

[0042] A method for in-situ performance enhancement of paper-based materials by aramid nanofibers in this embodiment, the specific preparation steps are as follows:

[0043] (1) Preparation of paper-based materials: The meta-aramid fiber paper-based composite material is prepared by traditional wet forming, and the ratio of meta-aramid fibrids to meta-aramid chopped fibers is 1:1

[0044] (2) Use DMSO, KOH and H for para-aramid chopped fibers 2 O is dissolved into aramid fiber nanofiber solution with a mass concentration of 0.5%;

[0045] (3) Immerse the meta-aramid fiber paper-based composite material prepared in step (1) in the aramid nanofiber solution obtained in step (2); when the meta-aramid fiber paper-based composite material is completely After soaking, wait for 20s to make it fully absorbed;

[0046] (4) Transfer the meta-aramid fiber paper-based composite material impregnated in step (3) to water for soaking, so that under the action of water, the aramid fiber nan...

Embodiment 3

[0050] A method for in-situ performance enhancement of paper-based materials by aramid nanofibers in this embodiment, the specific preparation steps are as follows:

[0051] (1) Preparation of paper-based materials: The meta-aramid fiber paper-based composite material is prepared by traditional wet forming, and the ratio of meta-aramid fibrids to meta-aramid chopped fibers is 1:1

[0052] (2) Use DMSO, KOH and H for para-aramid chopped fibers 2 O is dissolved into aramid nanofiber solution with a mass concentration of 0.75%;

[0053] (3) Immerse the meta-aramid fiber paper-based composite material prepared in step (1) in the aramid nanofiber solution obtained in step (2); when the meta-aramid fiber paper-based composite material is completely After soaking, wait for 20s to make it fully absorbed;

[0054] (4) Transfer the meta-aramid fiber paper-based composite material impregnated in step (3) to water for soaking, so that under the action of water, the aramid fiber nanofibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com