Electrolytic ozone generator

An ozone generator and electrode sheet technology, applied in the direction of electrolysis components, electrolysis process, electrodes, etc., can solve the problems of increased energy consumption, affected voltage stability, increased working voltage, etc., to improve service life, improve ozone concentration, The effect of increasing the amount of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

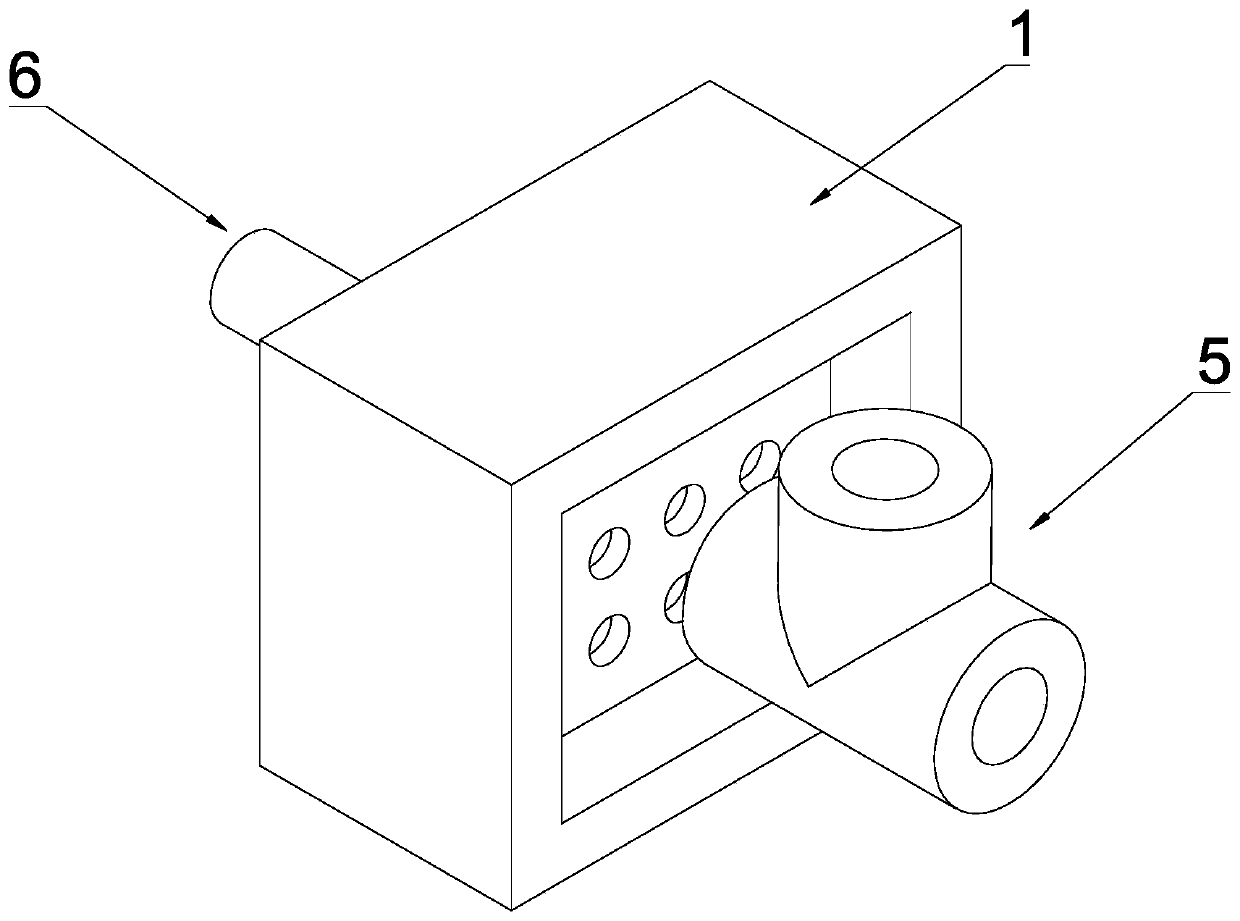

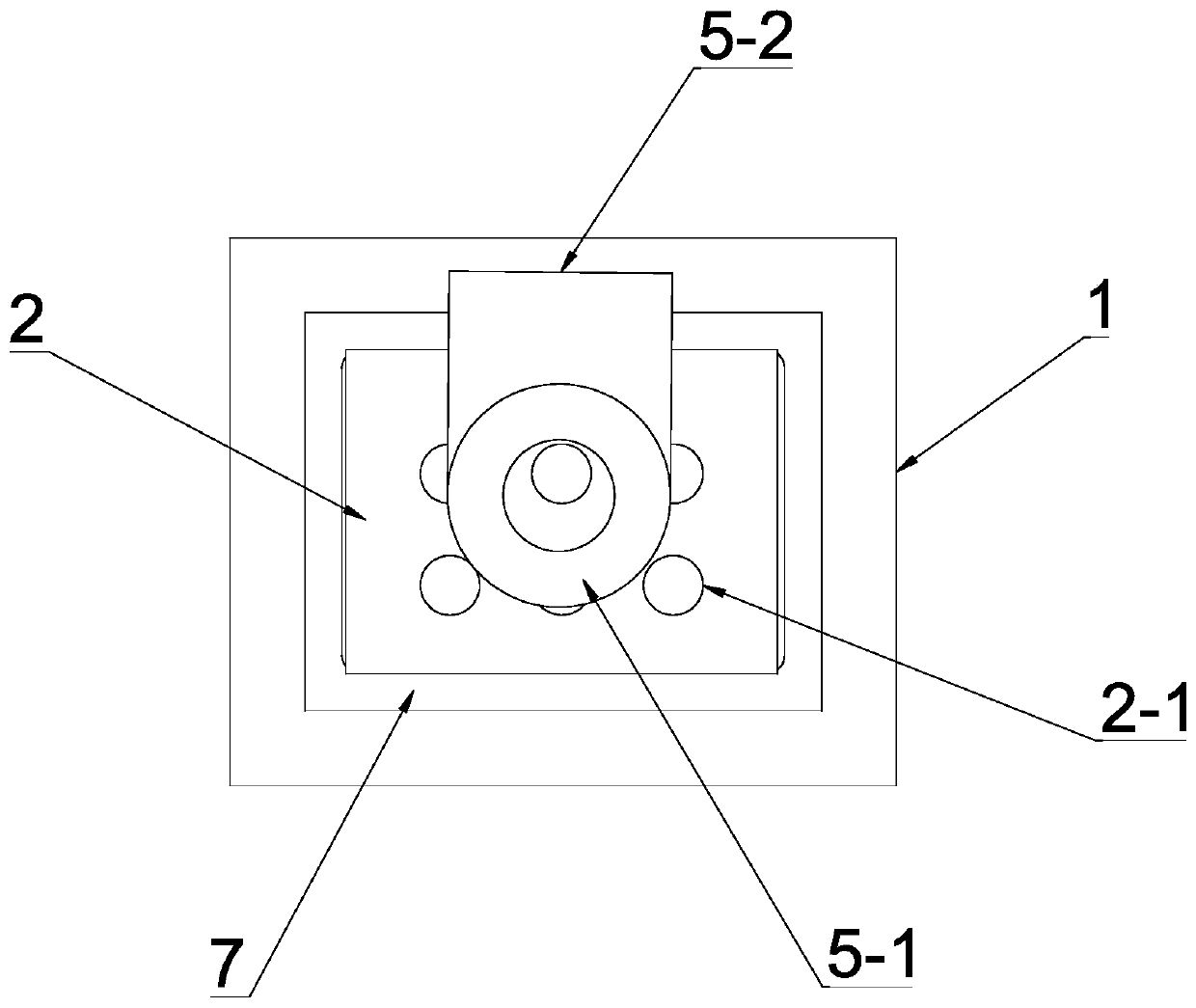

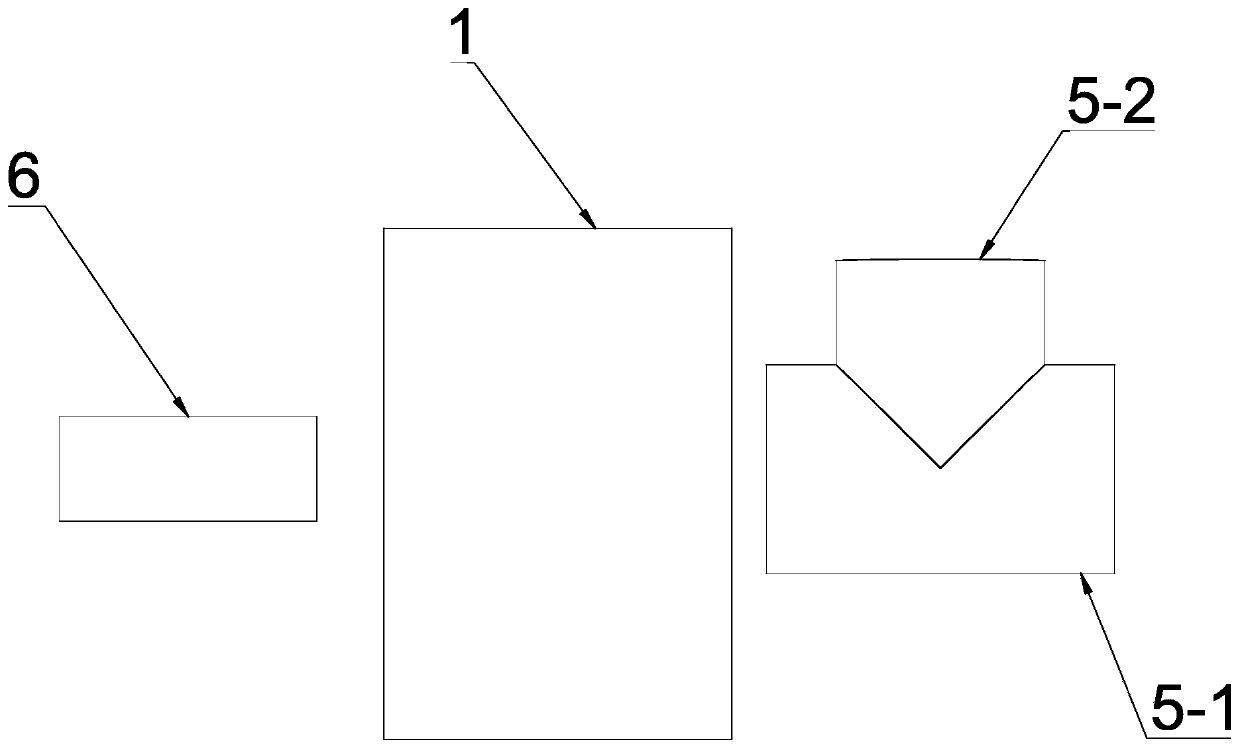

[0041] see Figure 1-Figure 5 , an electrolytic ozone generator in this embodiment includes a cavity 1, a positive electrode sheet 2 arranged inside the cavity 1, a negative electrode sheet 3, and a positive electrode sheet arranged between the positive electrode sheet 2 and the negative electrode sheet 3 A diaphragm 4 for proton exchange, a water inlet assembly 5 arranged at one end of the cavity 1 near the positive electrode sheet 2, and a spring 6 arranged at the end of the cavity 1 near the negative electrode sheet 3; wherein, the One end of the spring 6 acts on the negative plate 3, and the other end acts on the inner wall of the cavity 1; the water inlet end of the cavity 1 is provided with a water inlet, and the water outlet end is provided with a water outlet. The water inlet communicates with the water inlet assembly 5, the positive electrode piece 2 is close to the water inlet, and the negative electrode piece 3 is close to the water outlet. By setting the spring 6,...

Embodiment 2

[0061] Other structures in this embodiment are the same as in Embodiment 1, except that the first through hole 2-1 of the positive electrode sheet 2 and the second through hole 3-1 of the negative electrode sheet 3 are staggered from each other and axially Projections do not overlap. Adopting the above structure can effectively promote the surface contact area between the water body and the positive electrode sheet 2 or the negative electrode sheet 3, not only can promote the electrolysis efficiency but also can prepare ozone water with a higher concentration, so that the electrolysis product can be discharged circumferentially as soon as possible without inhibition, Improve cooling efficiency and reduce energy consumption.

Embodiment 3

[0063] see Figure 6-Figure 7 , the other structures in this embodiment are the same as those in Embodiment 1, except that the outlines of the cavity 1, the positive electrode sheet 2, the negative electrode sheet 3 and the diaphragm 4 are all circular, One side of the diaphragm 4 is parallel to the positive electrode sheet 2, and the other side of the diaphragm 4 is parallel to the negative electrode sheet 3; the positive electrode sheet 2 is provided with a circular first through hole 2-1, the number of the first through holes 2-1 is 6, one of which is set at the center of the positive electrode sheet 2, and the remaining 5 are in a circular array around the center of the positive electrode sheet 2; the negative electrode The sheet 3 is provided with a second through hole 3-1, the number of the second through hole 3-1 is 6, one of which is set at the center of the positive electrode sheet 2, and the remaining 5 surround the positive electrode sheet 2 The center of the circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com