Environment-friendly tanning method and device of leather

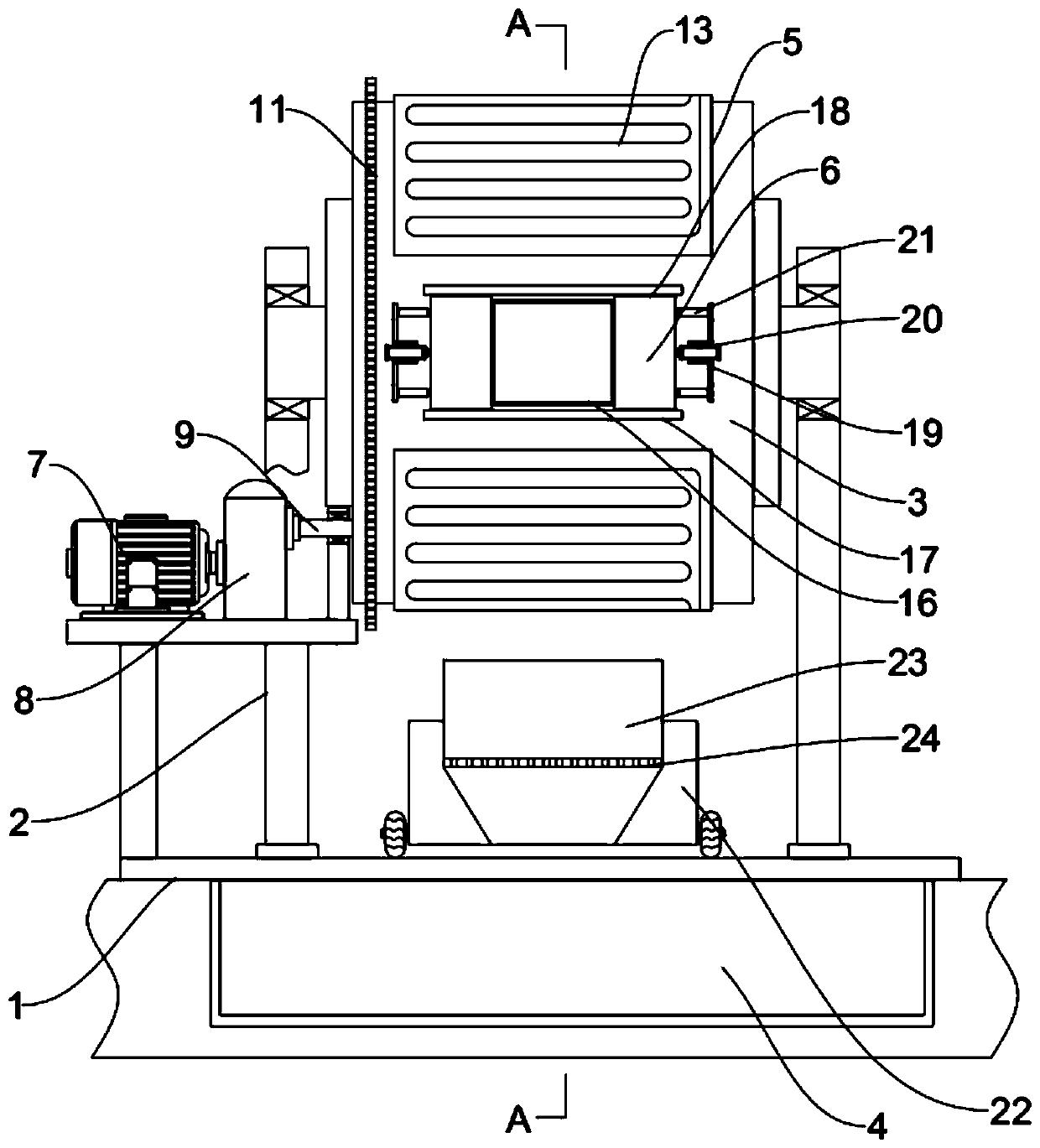

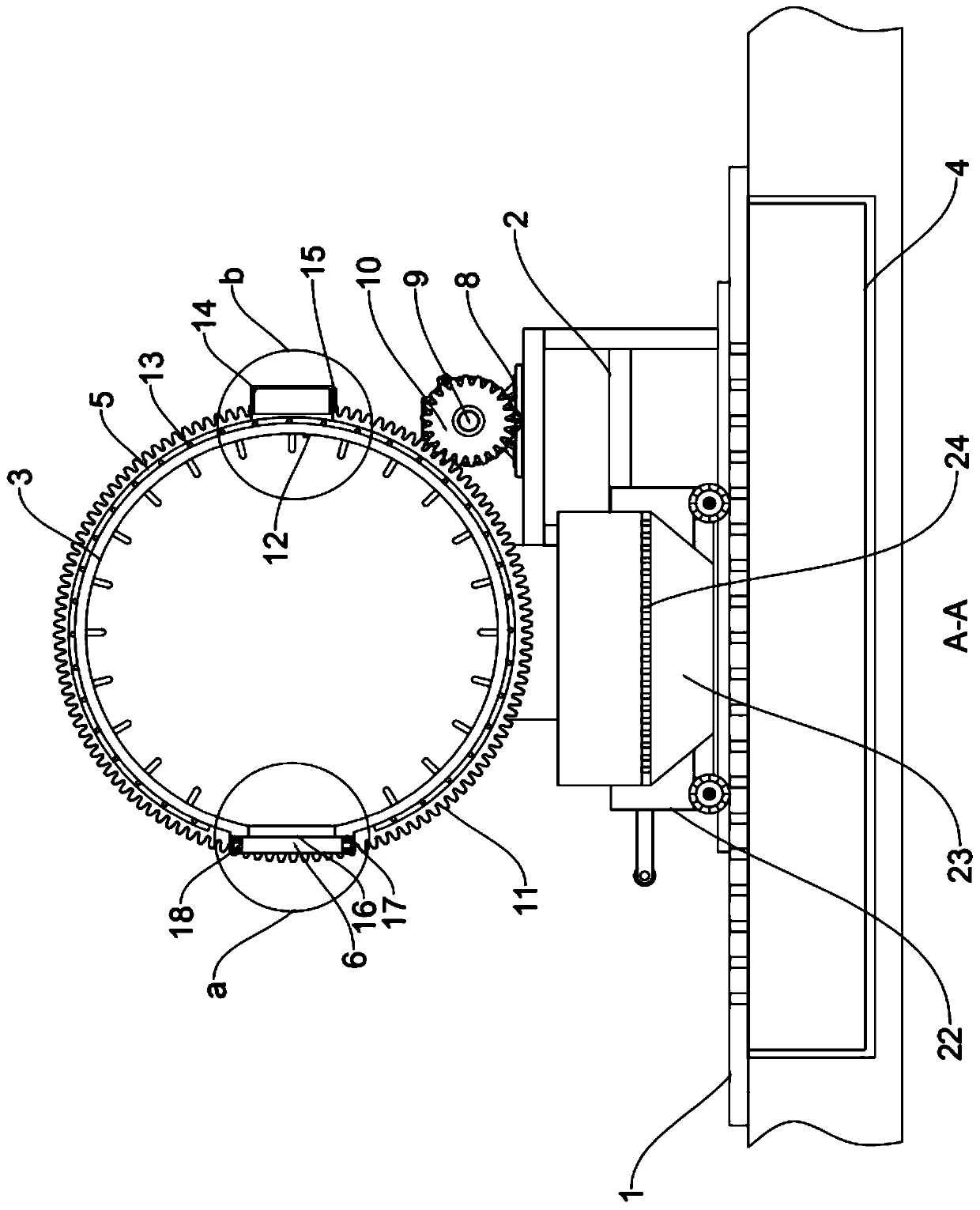

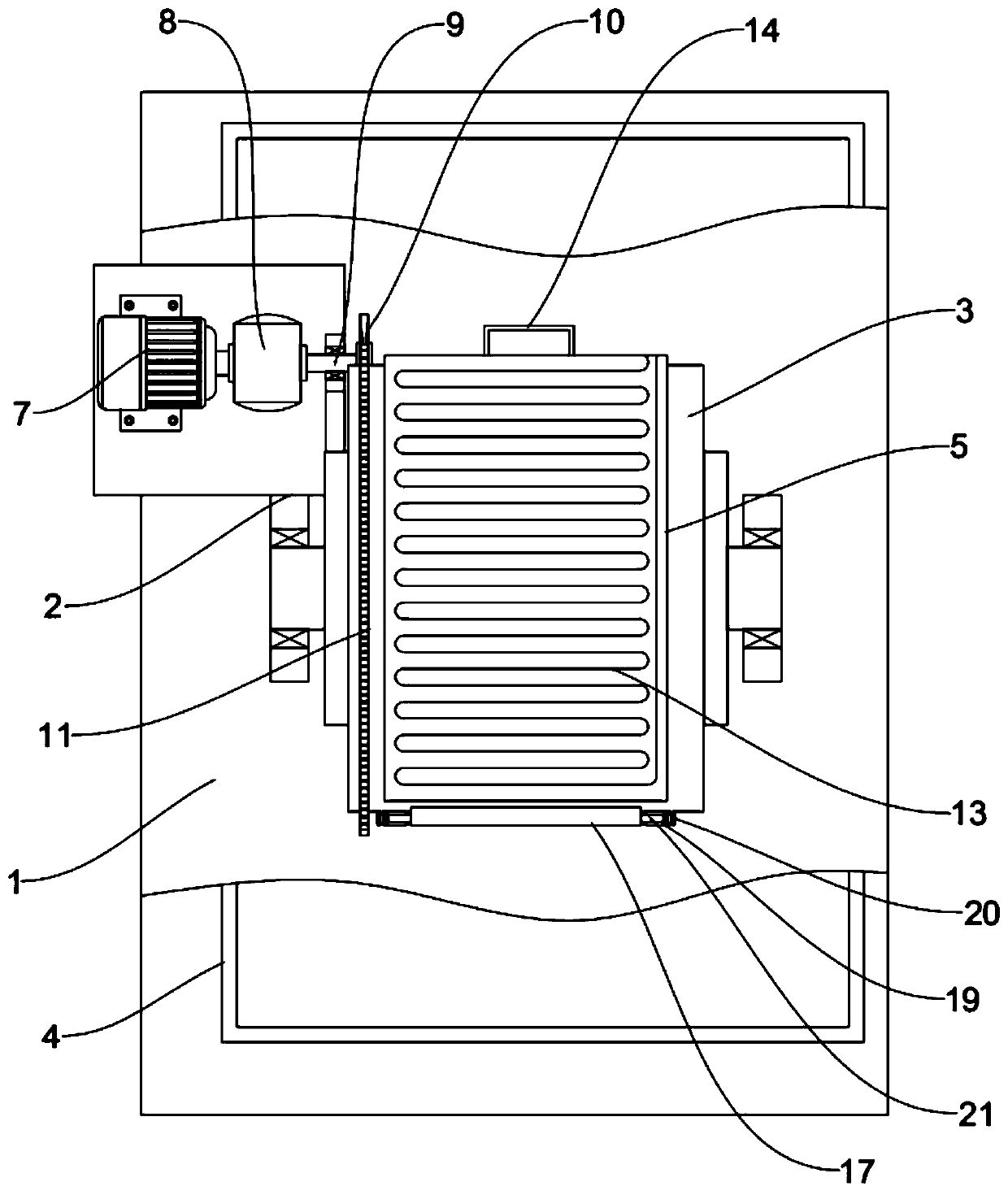

An environmentally friendly, tanning technology, applied in leather manufacturing, leather punching/punching/cutting, small raw hide/large raw hide/leather/fur treatment, etc., can solve the problems of long time consumption, complicated processing equipment, and high cost of tanning methods , to achieve the effect of ensuring sealing performance, improving tanning speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: in concrete implementation process, carry out leather tanning work according to following steps, comprise following operation steps:

[0040] Step S1, raw material pretreatment: the dried animal skin is soaked in water, fleshed out, degreased, depilated, sliced, pickled and softened to obtain raw hide;

[0041] Step S2, tanning treatment: put the raw hide obtained in step S1 into a tanning device, add water and a vegetable tanning agent, and soak for 5 hours. Based on the quality of the raw hide, add 2 parts of water, add 5% of the vegetable tanning agent, and add sulfuric acid Ammonium 1%, sodium chloride 8%, rotate for 2 hours, during the tanning process, maintain the temperature at 29 ° C, and obtain preliminary tanned leather. The vegetable tanning agent is composed of polyphenol derivatives with a complex structure. The amide groups of the collagen peptide chains are combined by hydrogen bonds to form multi-point cross-links for tanning. Vegetable tan...

Embodiment 2

[0044] Embodiment 2: in concrete implementation process, carry out leather tanning work according to following steps, comprise following operation steps:

[0045] Step S1, raw material pretreatment: the dried animal skin is soaked in water, fleshed out, degreased, depilated, sliced, pickled and softened to obtain raw hide;

[0046] Step S2, tanning treatment: put the raw hide obtained in step S1 into a tanning device, add water and a vegetable tanning agent, and soak for 6 hours. Based on the quality of the raw hide, add 2 parts of water, add 6% of the vegetable tanning agent, and add sulfuric acid Ammonium 1.5%, sodium chloride 10%, rotate for 3 hours, during the tanning process, maintain the temperature at 29 ° C, and obtain preliminary tanned leather. The vegetable tanning agent is composed of polyphenol derivatives with complex structure. The amide groups of the collagen peptide chains are combined by hydrogen bonds to form multi-point cross-links for tanning. Vegetable ta...

Embodiment 3

[0049] Embodiment 3: in concrete implementation process, carry out leather tanning work according to following steps, comprise following operation steps:

[0050] Step S1, raw material pretreatment: the dried animal skin is soaked in water, fleshed out, degreased, depilated, sliced, pickled and softened to obtain raw hide;

[0051] Step S2, tanning treatment: put the raw hide obtained in step S1 into a tanning device, add water and a vegetable tanning agent, and soak for 5.5 hours. Based on the quality of the raw hide, add 1.5 parts of water, add 5.5% of the vegetable tanning agent, and add sulfuric acid Ammonium 1.2%, sodium chloride 9%, rotate for 2.5 hours, during the tanning process, maintain the temperature at 29 ° C, and obtain preliminary tanned leather. The vegetable tanning agent is composed of polyphenol derivatives with a complex structure. The amide groups of the collagen peptide chains are combined by hydrogen bonds to form multi-point cross-links for tanning. Veg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com