A kind of high whiteness mgo substrate, preparation method and decorative board with the substrate

A high-brightness, decorative board technology, applied in the field of decorative materials, can solve the problems affecting the practicability of the glass magnesium board, cracking of the mortise and groove, low bonding strength, etc. The effect of internal bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

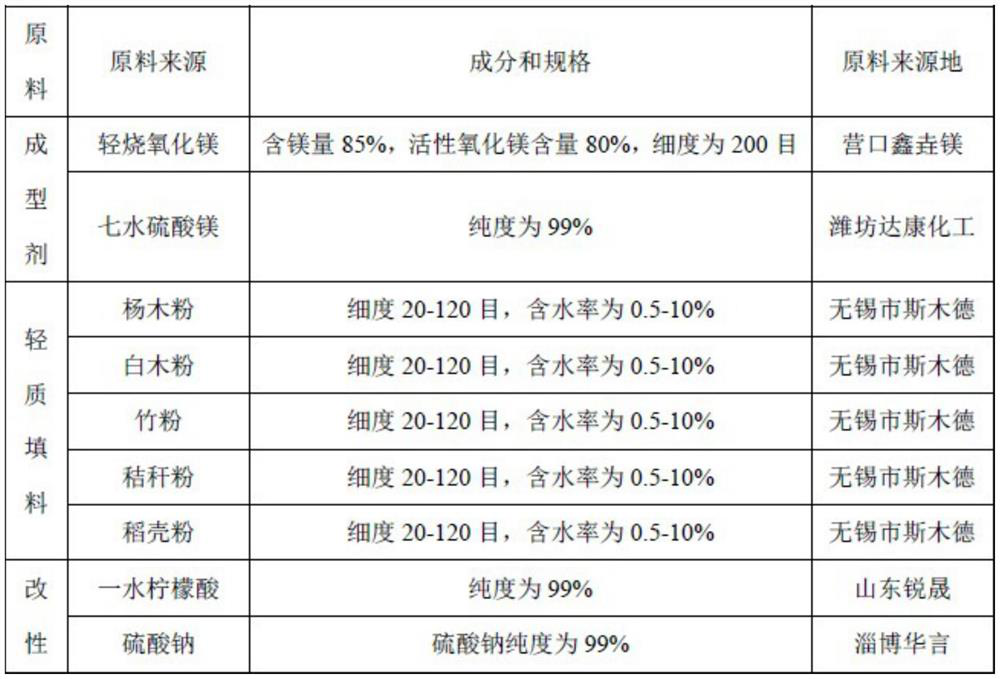

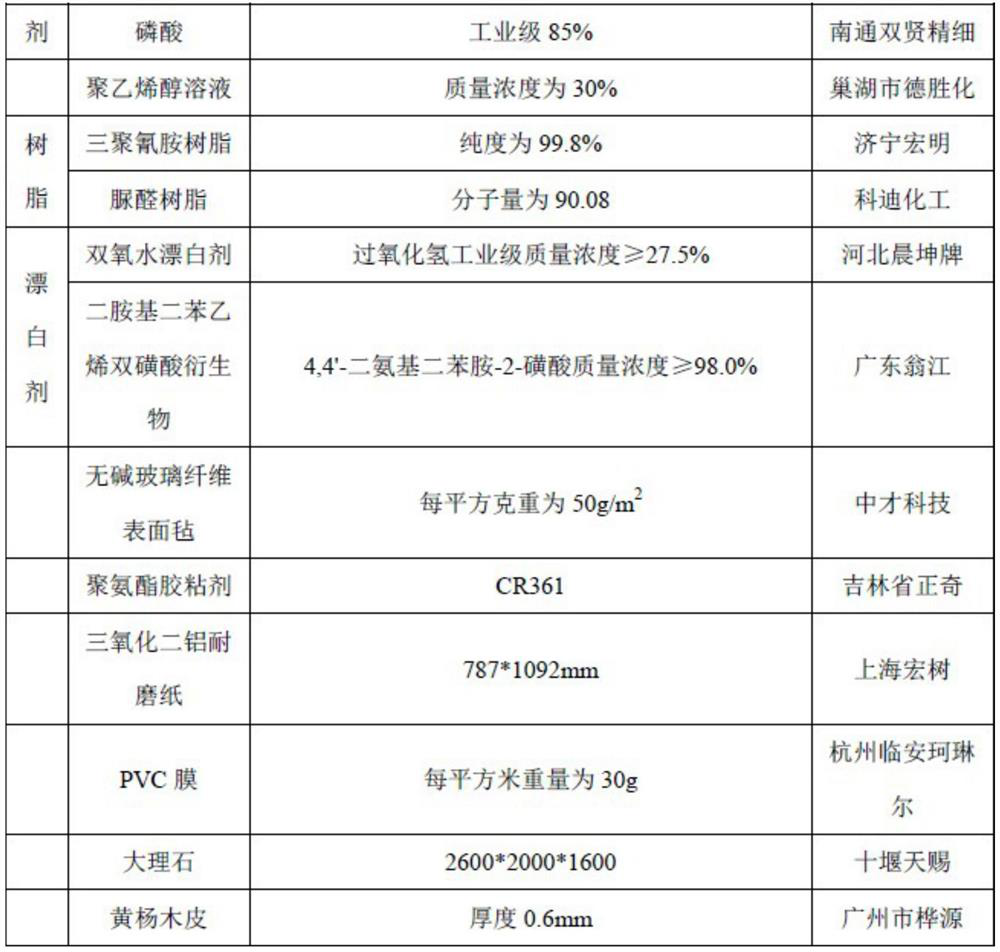

[0054] Components and proportioning ratios in each embodiment are shown in Table 2.

[0055] Components and proportioning of high-whiteness MGO substrate in each embodiment of table 2:

[0056]

[0057]

[0058]

[0059]

[0060]

[0061]

[0062] The preparation method of the high whiteness MGO substrate of above embodiment 1 to embodiment 11 is as follows:

[0063] S1. Select a 2440*1220*3 (mm) mold and clean the mold;

[0064] S2, lightly burned magnesium oxide powder, magnesium sulfate heptahydrate, mass concentration of 30% polyvinyl alcohol solution, plant powder, modifier will be weighed by weight powder in Table 2;

[0065] S2. Put the plant powder weighed according to Table 2 into the bleaching powder mixer, add hydrogen peroxide bleaching agent and 4,4'-diaminodiphenylamine-2-sulfonic acid in a mass ratio of 2:3 mixed bleaching agent and Submerge the plant powder, after soaking for 6 minutes, run the bleaching equipment to implement the stirring and...

Embodiment 8

[0098] Example 8, a high-whiteness MGO decorative board includes a surface layer and a substrate, and marble is used as the surface layer. The MGO substrate prepared according to the above-mentioned embodiment 2 is bonded on the cut marble plane through a polyurethane adhesive, and cured after 15 minutes. time, and then the marble is connected to the MGO substrate and cut open to obtain a marble surface composited with the MGO substrate. Whiteness MGO trim board.

Embodiment 9

[0099] Example 9, a high-whiteness MGO decorative board includes a surface layer and a substrate, boxwood veneer is used as the surface layer, and the MGO substrate prepared according to the above-mentioned embodiment 2 is bonded on the plane of the veneer by a polyurethane adhesive, after 15 minutes of curing time , to get a semi-finished product; then the semi-finished product is subjected to sanding, UV or UV after coloring, cutting, and grooving to obtain a high-whiteness MGO decorative board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com