Processing method of compression-enhanced fast growing wood

A processing method and fast-growing wood technology, applied in wood processing equipment, wood compression, wood treatment, etc., can solve the problems of reducing springback rate, bubbling, wood springback, etc., to improve hot pressing efficiency, shorten process time, The effect of accelerated drying and molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

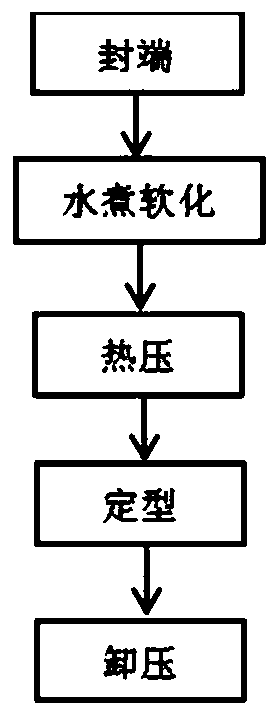

[0034] like figure 1 As shown, a kind of processing method of compressing and strengthening fast-growing wood of the present embodiment comprises the following steps:

[0035] S1: End capping: Dry and saw the fast-growing wood specimen after moisture content balance treatment, and use polypropylene wax to seal the surroundings of the fast-growing wood specimen (referring to the side wall and two ends of the fast-growing wood specimen, and the upper and lower surfaces are not exposed). Capping, for steam exhaust) capping; In the present embodiment, fast-growing wood is poplar, and the moisture content of fast-growing wood before capping is 12%-14%, and capping helps reduce the moisture of fast-growing wood, reduces heat pressure time.

[0036] S2: Boiling and softening: Boil and soften the fast-growing wood specimens with 100°C water for 20 minutes; use boiling water for surface softening to shorten the softening time and improve the softening efficiency.

[0037] In other em...

Embodiment 2

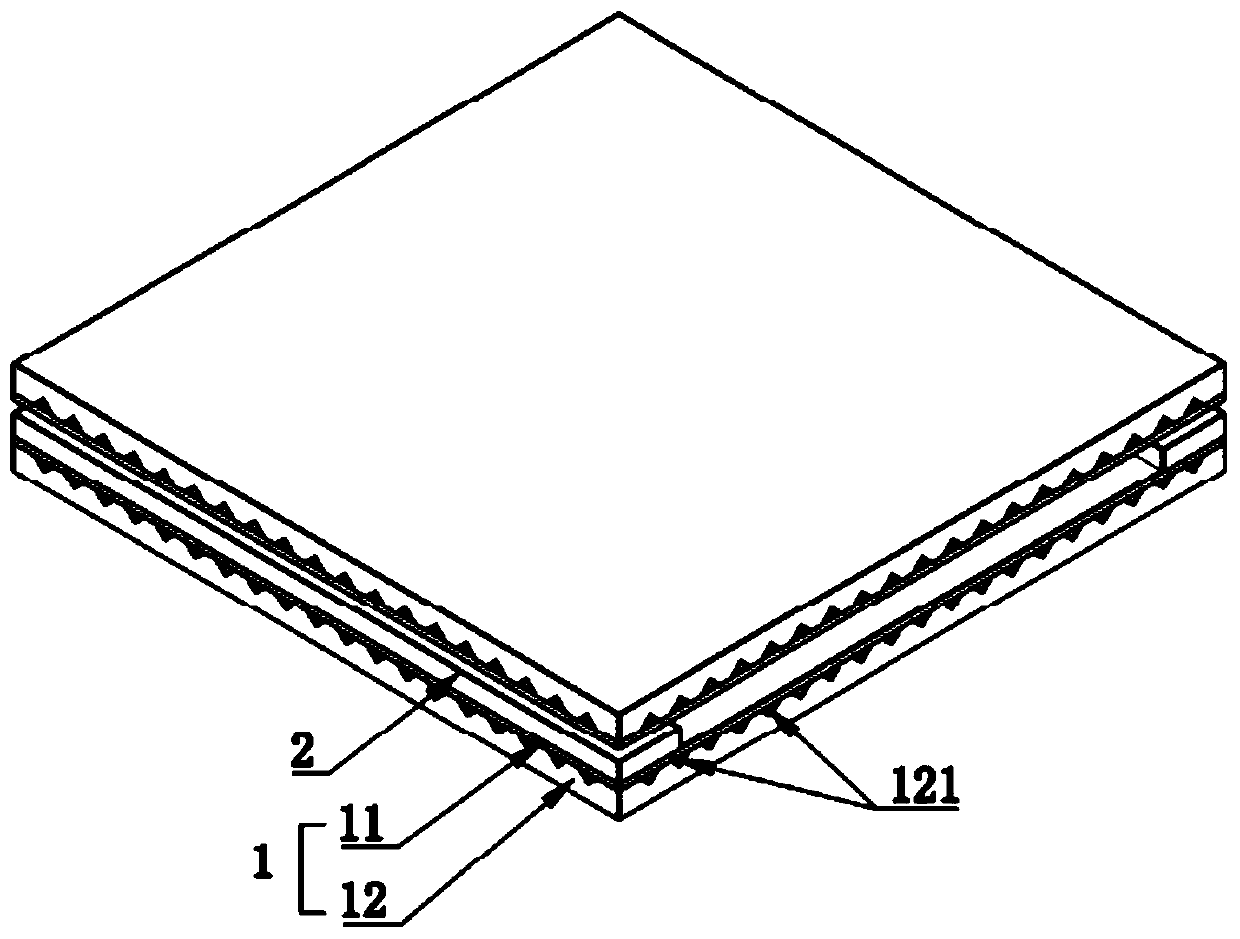

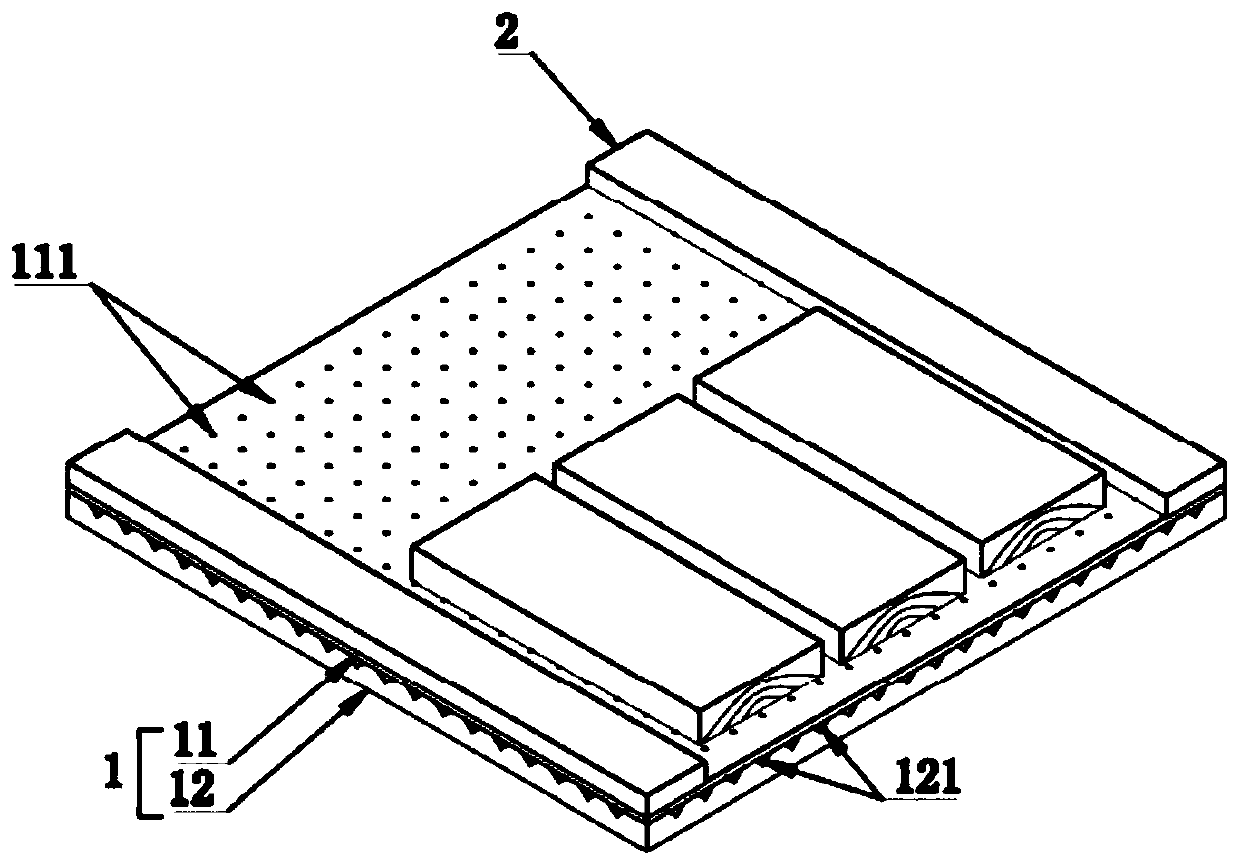

[0053] This embodiment is roughly the same as Embodiment 1, except that the pressing plate 1:

[0054] Different from Embodiment 1, the pressing plate 1 is composed of an inner pressing plate 11 and an outer pressing plate 12, and is a composite plate. The pressing plate 1 of this embodiment is a single plate, such as Figure 7-9 as shown, Figure 8 The middle arrow shows the pressure direction.

[0055] The release hole 111 is opened on one side of the pressing plate 1 and is set close to the side of the fast-growing material specimen, and the groove 121 is opened on the other side of the pressing plate 1 and is set away from the side of the fast-growing wood specimen.

[0056] Dimensions of the pressure plate 1 in this embodiment: format: 500×500×3mm (length×width×thickness), groove 121: 500×2×1.5mm (length×width×depth) interval 5mm, release hole 111 diameter 1mm, interval 5mm. The cross section of the groove 121 in this embodiment is rectangular.

[0057] The pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com