Chassis structure of sliding block type wheel set orbital robot

An orbital robot and slider-type technology, used in manipulators, manufacturing tools, etc., can solve the problems of high impact of the motor, avoid positioning errors, ensure the feasibility of the mechanism, and increase the compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0039] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

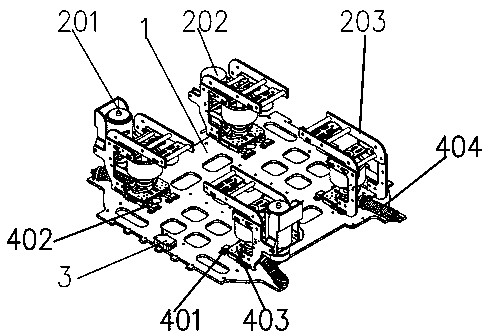

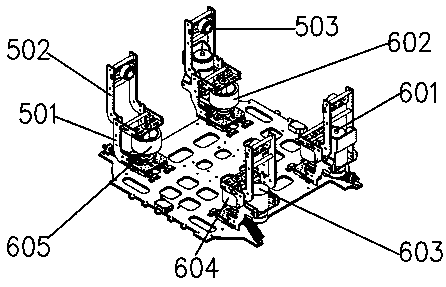

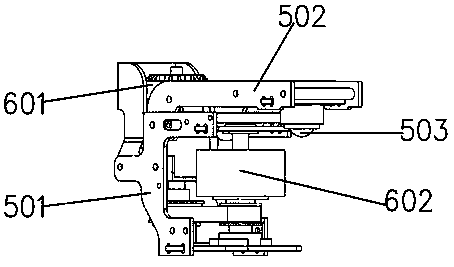

[0040] Such as figure 1 As shown, the present invention provides a chassis structure of a slider type wheel set track robot, which includes:

[0041] Bottom plate 1, which is horizontally arranged under the track and the axis of the bottom plate 1 is in the same direction as the axis of the track;

[0042] and a linear motion wheel set, which is located above the bottom plate 1, the linear motion wheel set is mounted on the track and is in contact with the outer surface and the upper surface of the track, and the linear motion wheel set is two pairs, And each pair of linear mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com