Dual-mode cooperative robot control system

A control system and robot technology, applied in the field of robots, can solve problems such as execution errors and lack of autonomous processing capabilities, and achieve the effect of improving processing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

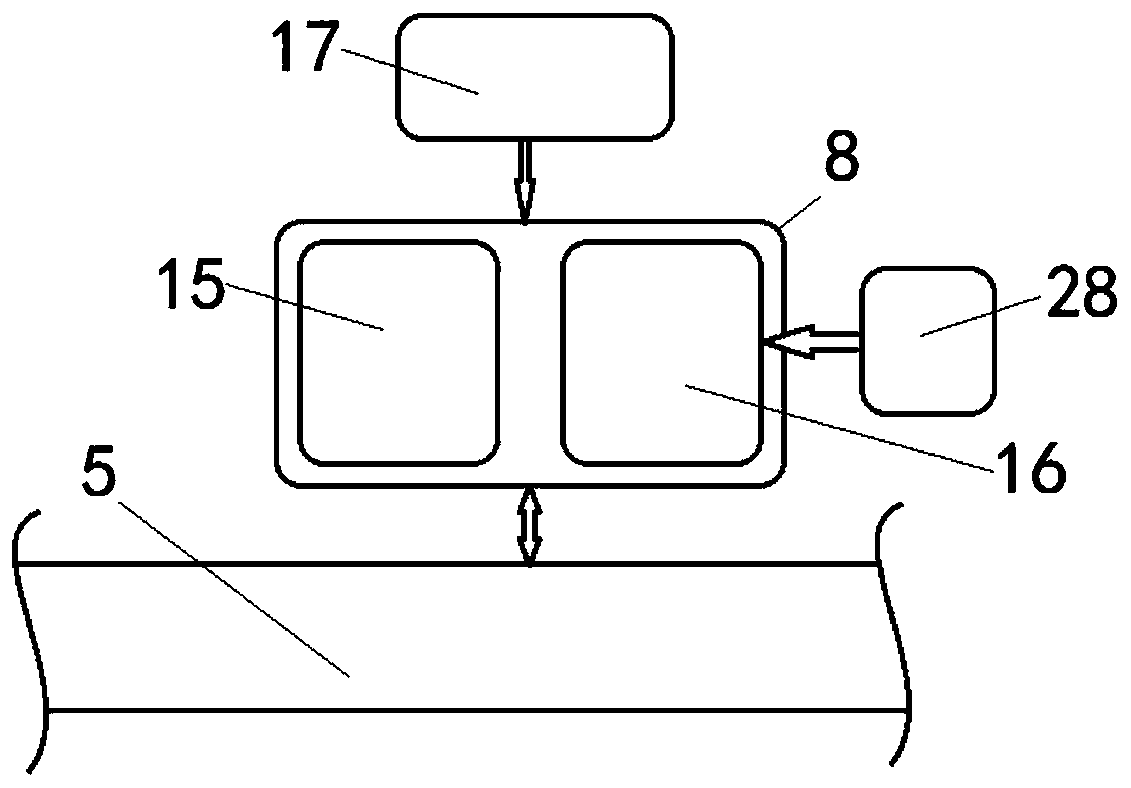

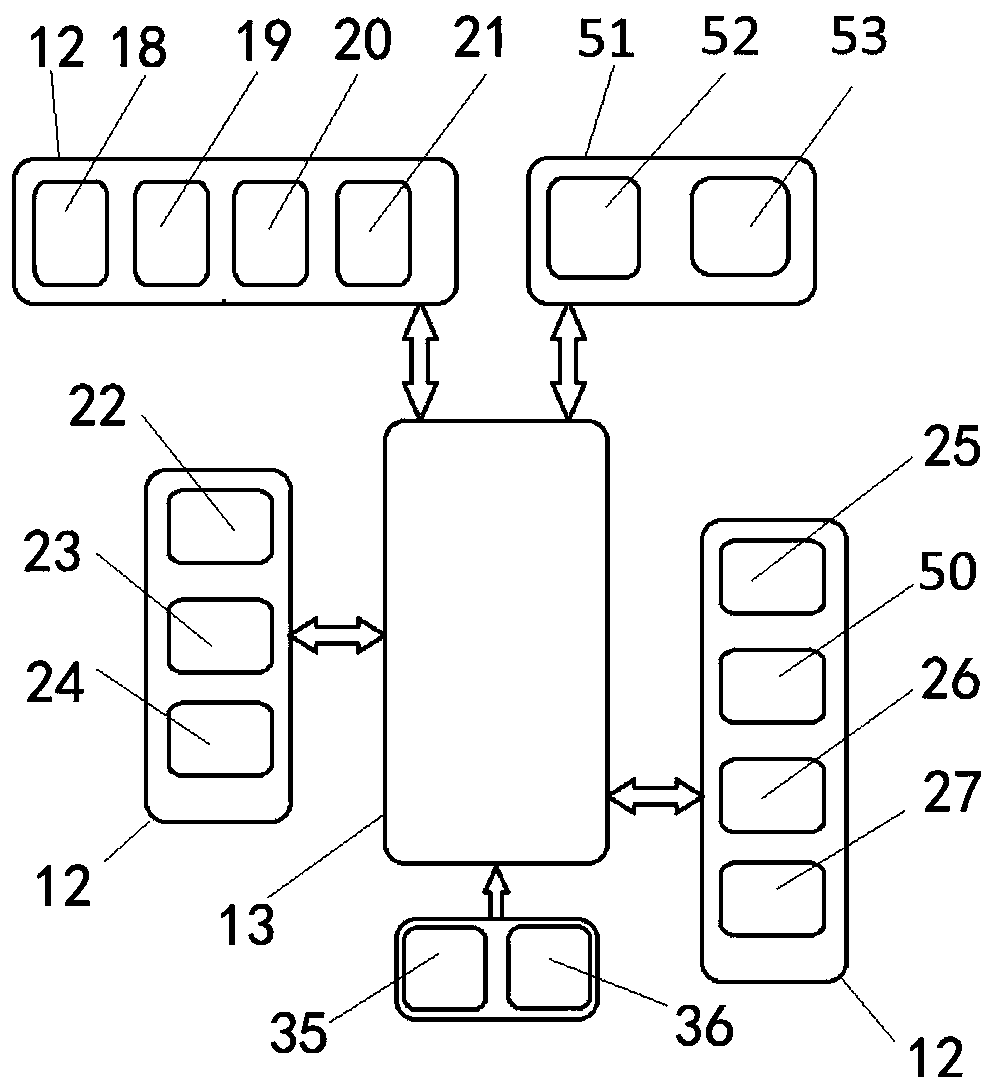

[0027] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, a dual-mode collaborative robot control system includes: a robot 1 and a control background 2 for controlling the robot 1, the control background 2 is provided with a main communication module 3, and the robot 1 is provided with a secondary communication module 4. There is data communication between the main communication module 3 and the secondary communication module 4; wherein, the control background 2 is provided with a bus 5 electrically connected to the main communication module 3, and connected to the bus 5 An electrically connected task management system 6, a path planning system 7, an operation control system 8, and a status display system 9; , the processor 13 for the working mechanism 11 and the sensing system 12 to work; the processor 13 is electrically connected to the secondary communication module 4 .

[0028] In the above setting, the auxiliary comm...

Embodiment 2

[0030] The robot 1 is provided with an autonomous working module 14, and the autonomous working module 14 is electrically connected to the processor 13; the operation control system 8 includes a trusteeship module 15 and a manual control module 16, and is used to A mode selection switch 17 for arbitrary switching between the module 15 and the manual control module 16; the hosting module 15 and the manual control module 16 are electrically connected to the bus 5 respectively.

[0031] In this setting, the working mode of the robot 1 is selected through the mode selection switch 17. Usually, the robot 1 executes the preset work order of the task management system 6 through the autonomous working module 14, and handles complicated and mechanical activities. When the management personnel in the backstage hand over the authority of the robot 1 to the manual control module 16 through the mode selection switch 17, the robot 1 stops working autonomously and performs actions according t...

Embodiment 3

[0033] The perception system 12 includes a binocular camera 18, an infrared camera 19, a fisheye lens 20, an omnidirectional microphone 21, a temperature and humidity sensor 22, a spectrometer 23, and an electronic counter 24 electrically connected to the processor 13; Electrically connected to the processor 13 , the pressure sensor 25 , angular velocity sensor 26 , torque sensor 27 and tactile sensor 50 are used to collect motion data of the working mechanism 11 .

[0034] Specifically, the robot 1 collects 3D images in the working environment through the binocular camera 18, and passes through the status display system 9, so the recorded content can be displayed to the manager in 3D form; and the infrared camera 19 can realize the night vision function. , so that the robot 1 can provide night vision images to the status display system 9; the fisheye lens 20 collects panoramic images around the robot 1, so the manager can freely view the images of the environment where the rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com