Method and apparatus for surface scratch repair

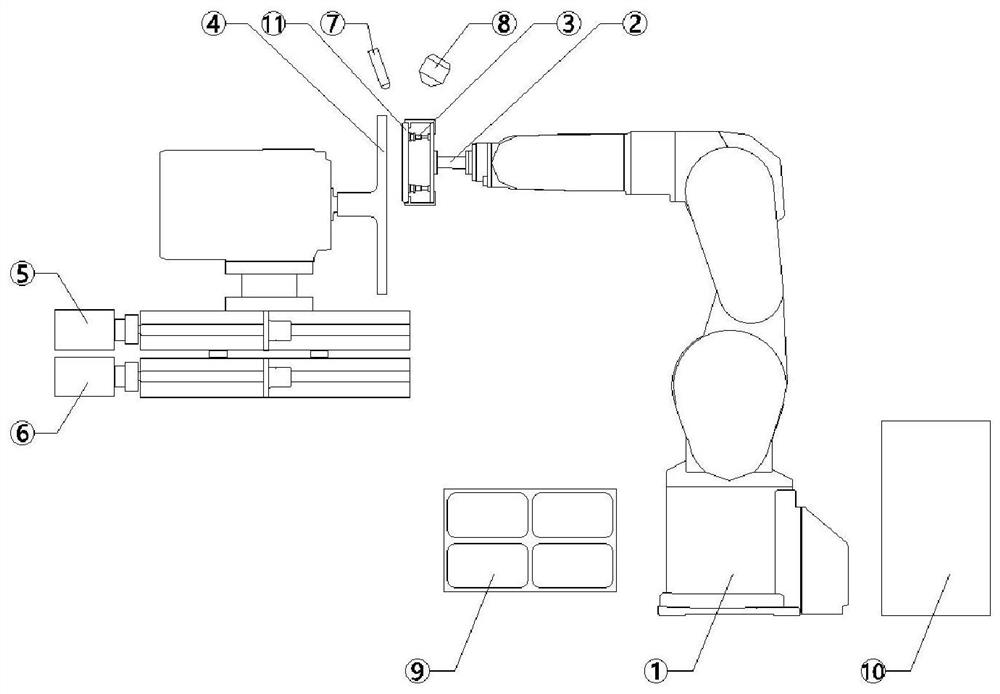

A technology for scratches and equipment, applied in metal processing equipment, grinding/polishing equipment, machine tools suitable for grinding workpiece planes, etc., can solve the problem of damaging the internal circuit of electronic products, does not allow disassembly and separation, and cannot meet the needs of use Requirements and other issues to achieve the effect of removing or reducing scratches and restoring smoothness and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

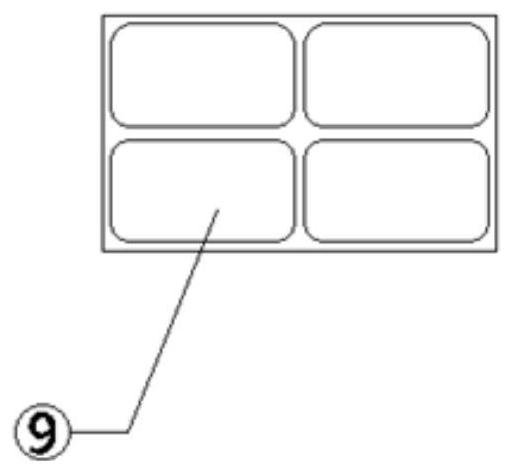

Method used

Image

Examples

Embodiment 1

[0130] Use the equipment for repairing surface scratches of the present invention to repair the glass surface of the mobile phone according to the following process conditions.

[0131] 1. Coarse polishing process conditions

[0132] (1) Use ABRALON J3 500 abrasive sheet, wherein the particle size of the abrasive is 30 microns;

[0133] (2) above-mentioned abrasive sheet is installed on the circular grinding disc frame that diameter is 6 inches (or 6 inches);

[0134] (3) The speed of the grinding disc is 3500 revolutions per minute (RPM), and the direction is clockwise (positive);

[0135] (4) The pressure value when the grinding disc is in contact with the glass surface is 1N;

[0136] (5) Coarse throwing time: 3 minutes;

[0137] (6) Coarse throwing path: proceed along the periphery, continuously reducing the radius until the middle; and

[0138] (7) The number of cycles is 8 times.

[0139] 2. Coarse throwing process

[0140] (1) The mechanical arm automatically shif...

Embodiment 2

[0163] Except that the rough polishing process uses ABRALON J3 600, the grinding disc speed is 4000 revolutions per minute (RPM), and the pressure when the grinding disc is in contact with the glass surface is 3N, the rough polishing and mirror polishing processes are carried out in the same manner as in Example 1.

[0164] In Example 2, the surface of the mobile phone glass is smooth after the rough polishing and mirror polishing processes, without visible scratches.

Embodiment 3

[0166] Except for fixing the position of the mobile phone and grabbing the abrasive disc by the mechanical arm to carry out the rough polishing and mirror polishing process, the rough polishing and mirror polishing process is carried out in the same manner as in Example 1.

[0167] In Example 3, the surface of the mobile phone glass is smooth after the rough polishing and mirror polishing processes, without any scratches visible to the naked eye.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com