Device and method for rapidly heating and melting female die of complex cavity shell layer

A rapid heating and complex type technology, applied in the direction of mold, core, mold composition, etc., can solve the problems of high energy consumption and high cost of sewage discharge, and achieve the effects of improving work efficiency, reducing costs and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

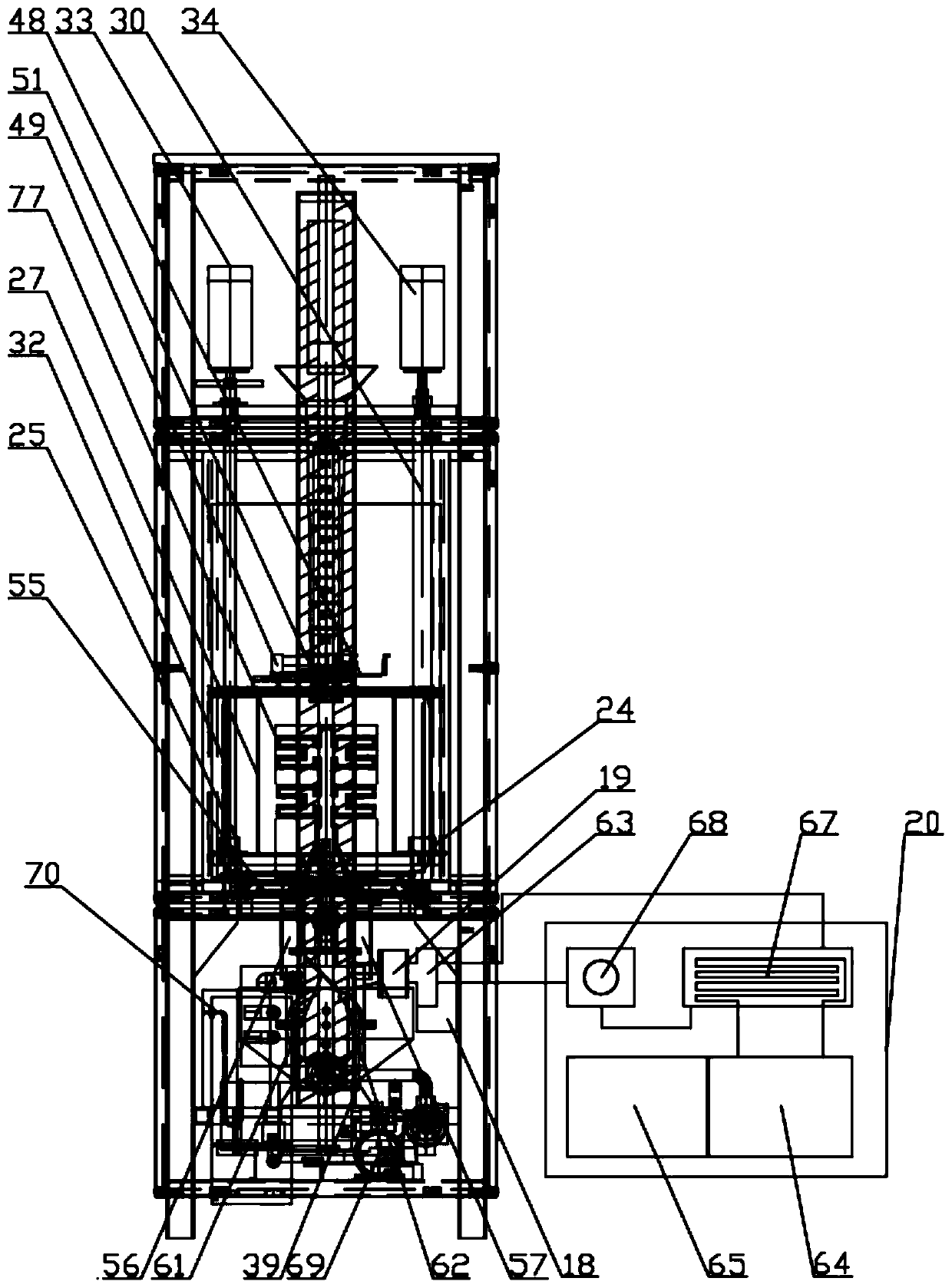

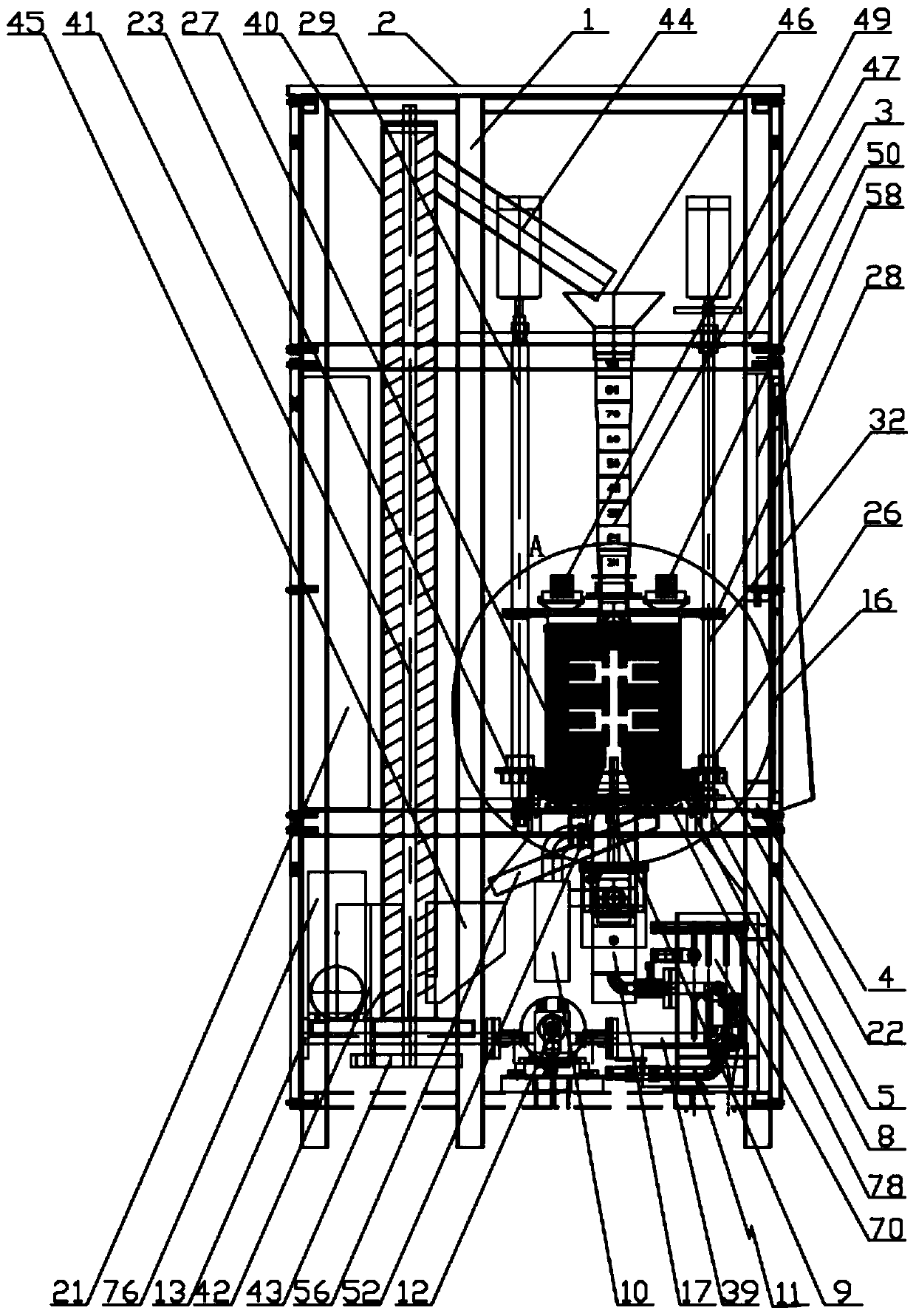

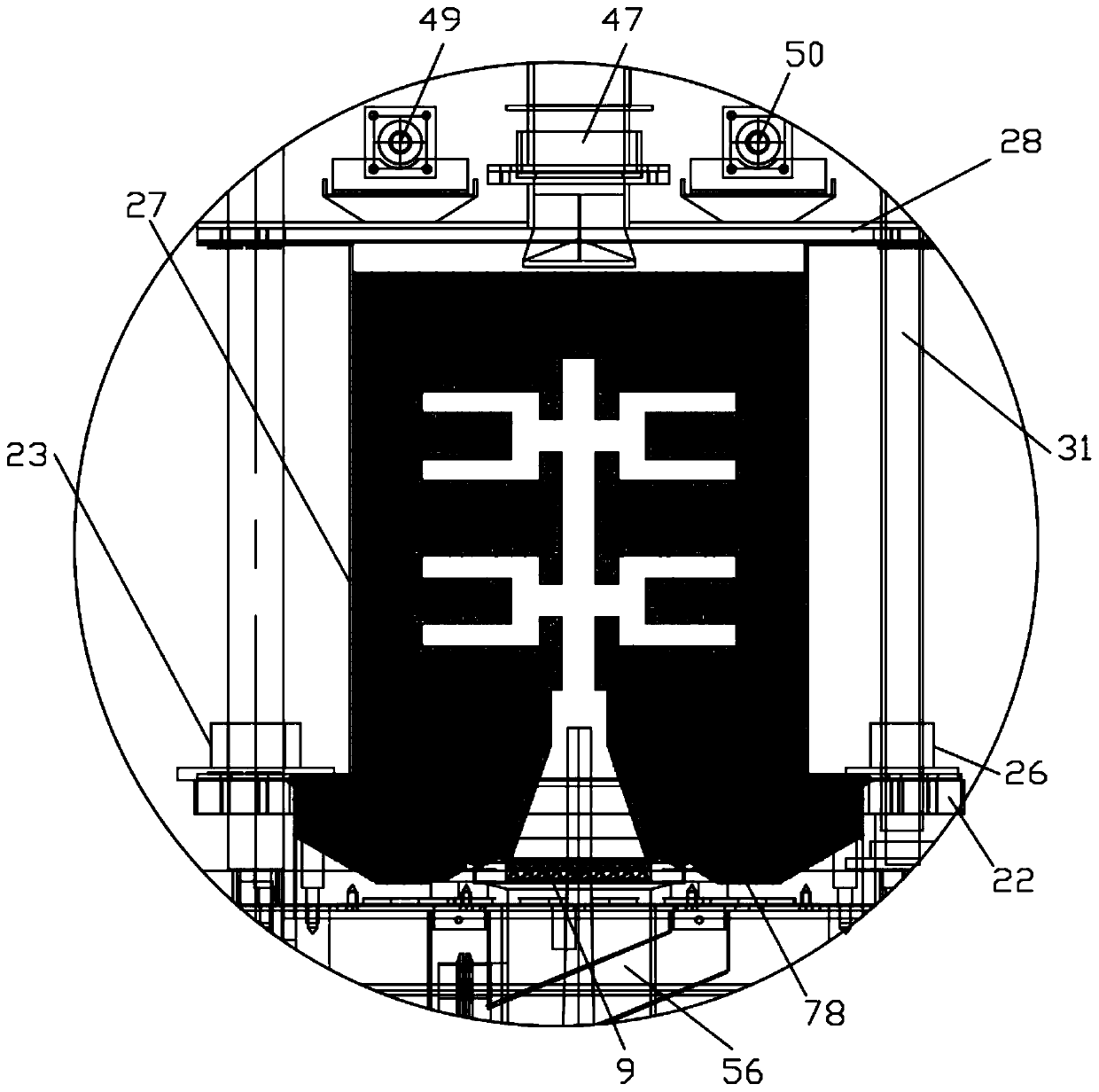

[0090] like Figure 1-Figure 28 As shown, the device for rapid heating and melting of the complex cavity shell of the present embodiment includes a frame 1 of a frame structure, the outside of the frame 1 is covered with a shell 2, and the inside of the frame 1 is installed with parallel The upper fixed plate 3 and the lower fixed plate 4, and the lifting shield 6 and the lifting mechanism 7 are installed between the upper fixed plate 3 and the lower fixed plate 4;

[0091] A hot gas circulation system 10 and a hot oil circulation system 11 are installed at the bottom of the frame 1;

[0092] The bottom of the frame 1 is fixed with a heat preservation delivery pump 12, one end of the heat preservation delivery pump 12 is connected with a first heat preservation delivery pipeline 13, and the other end of the heat preservation delivery pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com