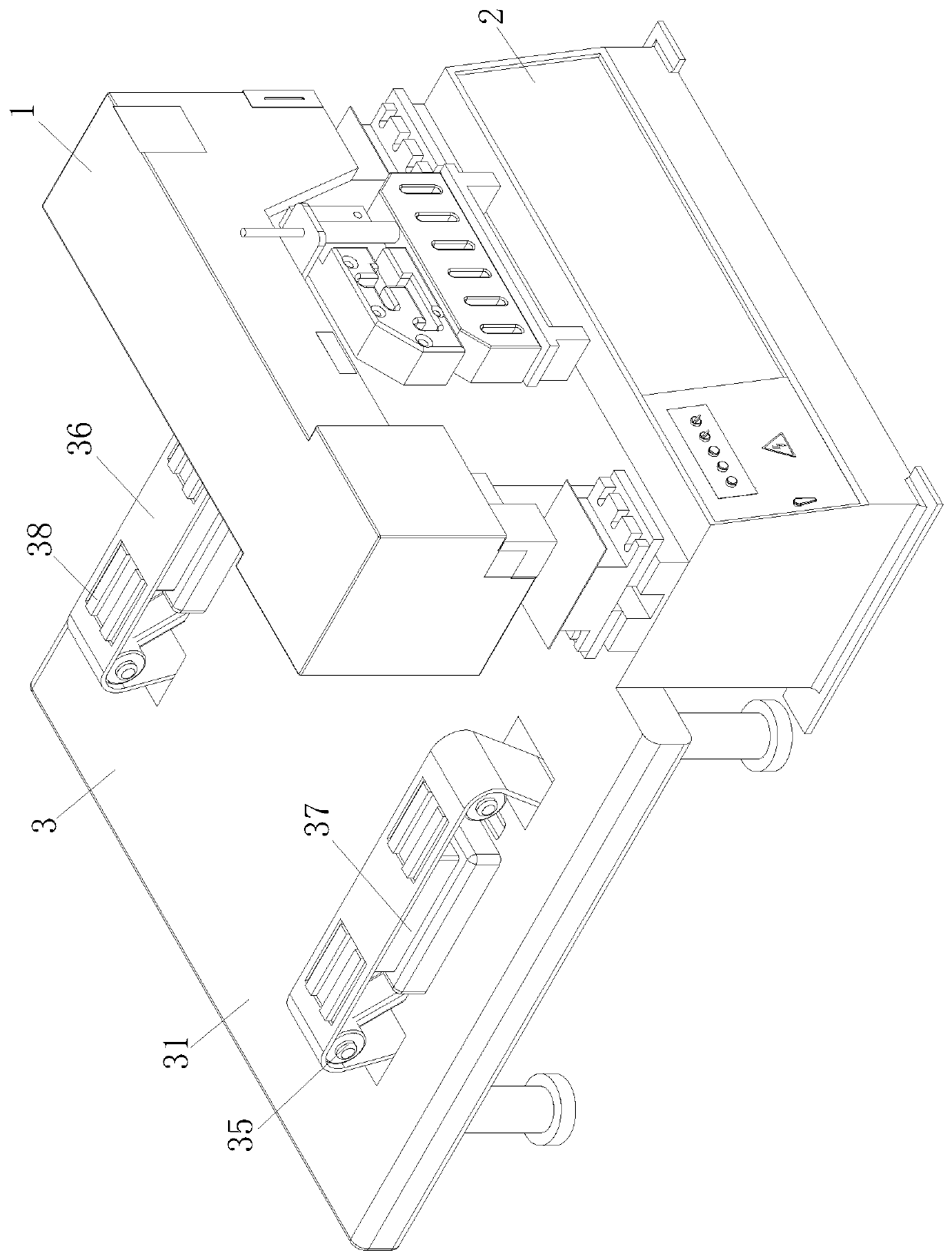

Full-automatic punching shearing machine

A punching and shearing machine, fully automatic technology, used in conveyors, metal processing equipment, feeding devices, etc., can solve the problems of punching and shearing machine failure, affecting punching and shearing processing quality and processing efficiency, etc. The number of small maintenance and adjustment of the blank position, the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

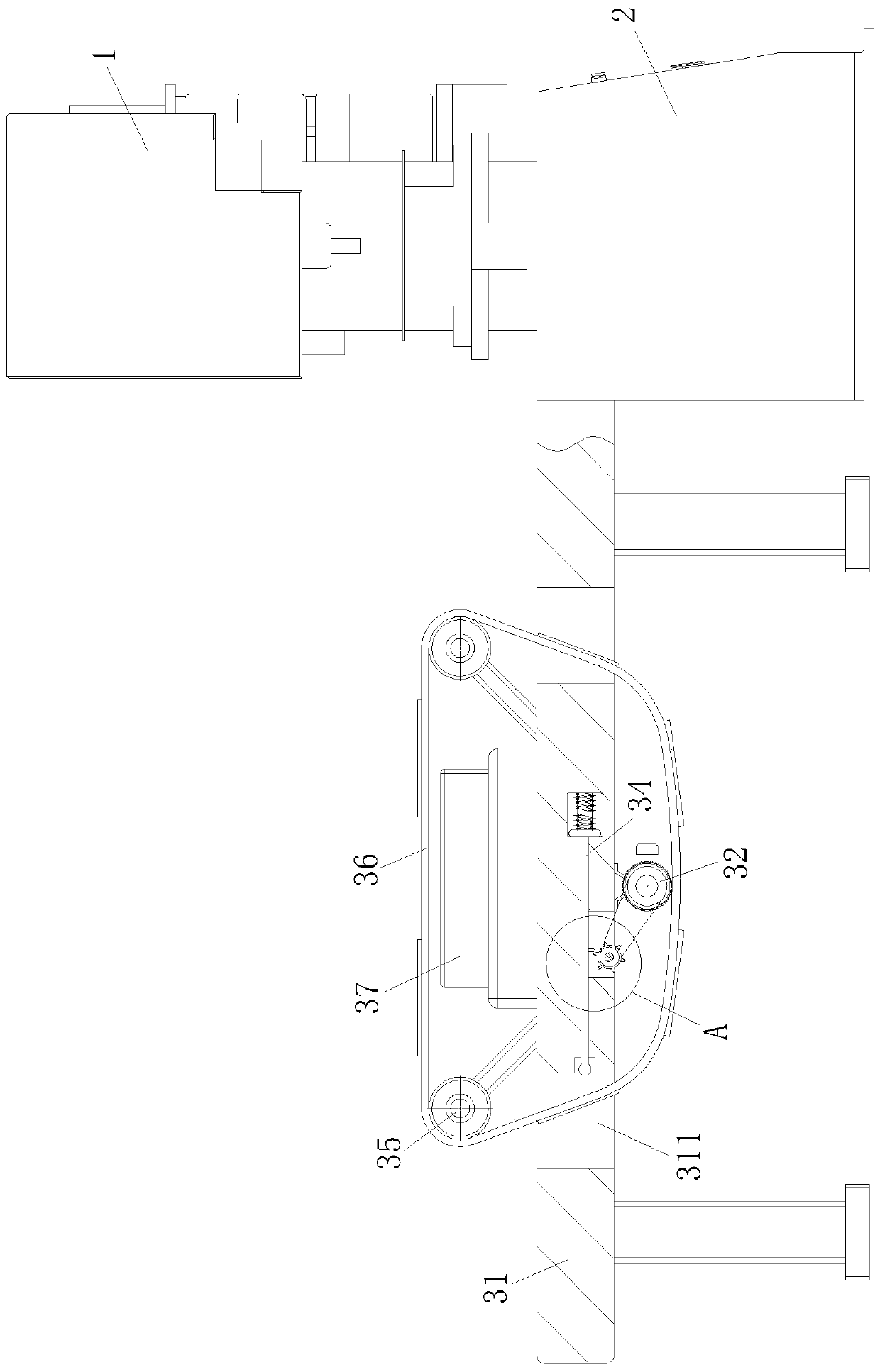

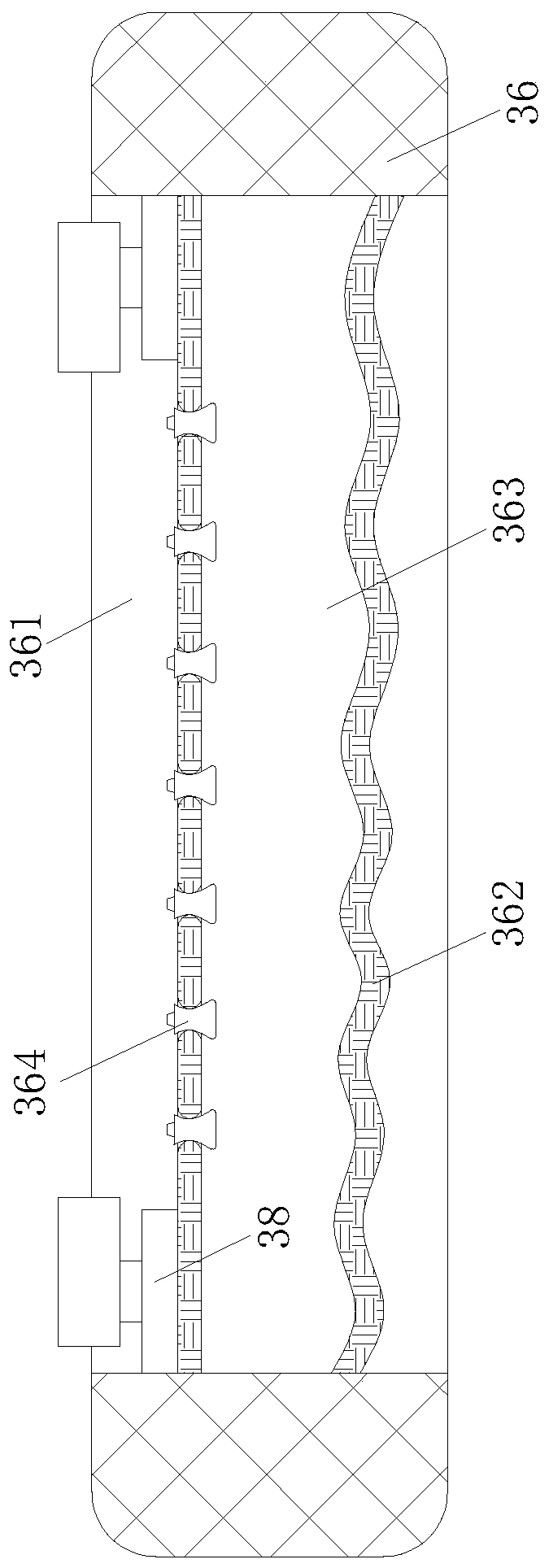

[0024] As an embodiment of the present invention, the push rod 34 is composed of a main rod 342 and an elastic rod 343; the elastic rod 343 is symmetrically installed at the end of the main rod 342, and the end of the elastic rod 343 is provided with a rolling ball 344, and Elastic bar 343 is provided with wave-shaped projection on the side wall that contacts with transmission belt 36; By the cooperation of main bar 342, elastic bar 343 and rolling ball 344, reduce the jacking force of vertical its side wall that transmission belt 36 suffers; , when the staff needs to process the blank through the punching and shearing machine, the staff first places the blank on the transmission belt 36, and at this time, the motor 32 is energized, so that the rotation of the output end of the motor 32 drives the transmission belt 36 to rotate, thereby turning the transmission belt The blank on the 36 is transported to the punching and shearing table 1. At this time, the punching and shearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com