A kind of solar cell module and preparation method

A technology of solar cells and components, applied in the field of solar cells, can solve problems such as inconvenient processing, slivers, and easy occurrence of hidden cracks, and achieve the effects of reducing usage, improving reliability, and reducing the risk of slitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The application provides a method for preparing a solar cell assembly, see Figure 1 to Figure 7 , including the following steps:

[0051] Step S1: sequentially laying the first packaging film 2, the battery string, the second packaging film 5 and the front cover 6 on the rear cover 1 to obtain a laminate;

[0052] Step S2: laminating the laminate to obtain a solar cell module.

[0053] Wherein, the battery string includes a plurality of battery slices 3 connected in a head-to-tail overlapping manner. Moreover, in the present application, there may be multiple battery strings.

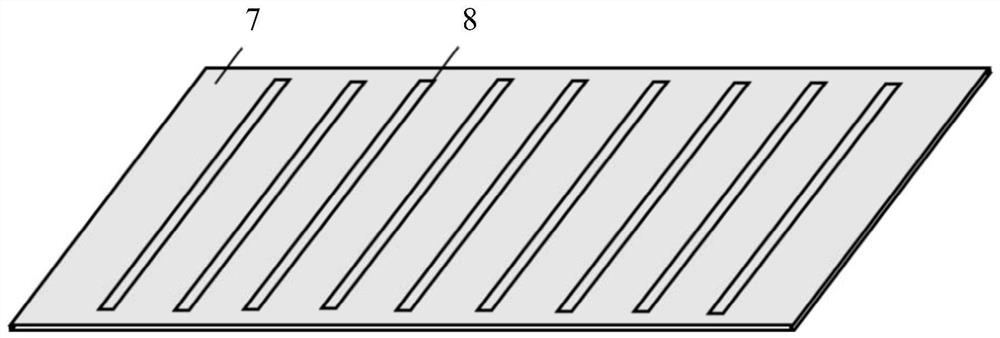

[0054] The first encapsulation film 2 and / or the second encapsulation film 5 adopt Figure 1 to Figure 3 The encapsulating adhesive film with a local protrusion 8 structure is shown. Specifically, the encapsulant film with the structure of partial protrusions 8 includes a main body 7 and a plurality of local protrusions 8 disposed on the main body 7 and corresponding to the overlapping areas...

Embodiment 1

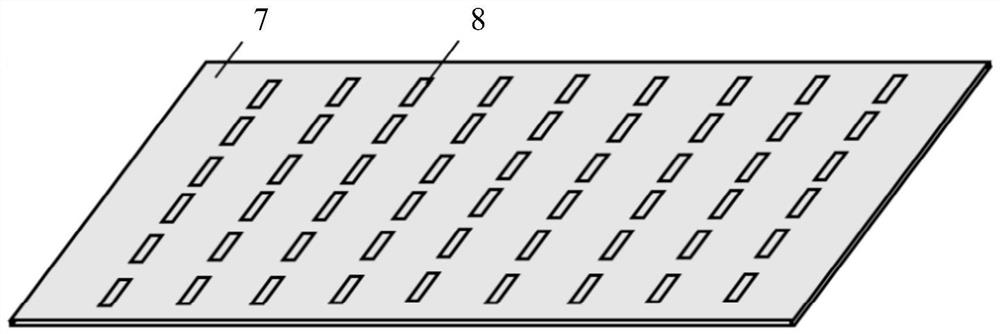

[0089] The solar cell encapsulating adhesive film of this embodiment includes: a main body 7 and a plurality of local protrusions 8, the main body 7 and the local protrusions 8 are integrally arranged to form an integral adhesive film, and the solar cell encapsulating adhesive film is an EVA adhesive film; wherein, the main body 7 The gram weight is 420g / m 2 , the weight of local protrusion 8 is 40g / m 2 ; The local protrusion 8 along the direction perpendicular to the extension of the battery string is a segmented protrusion, see figure 1 .

Embodiment 2

[0091] The solar cell encapsulating adhesive film of this embodiment includes: a main body 7 and a plurality of local protrusions 8, the main body 7 and the local protrusions 8 are integrally arranged to form an integral adhesive film, and the solar cell encapsulating adhesive film is an EVA adhesive film; wherein, the solar cell The grammage of the packaging film main body 7 is 450g / m 2 , the weight of local protrusion 8 is 60g / m 2 ; The local protrusion 8 along the direction perpendicular to the extension of the battery string is a continuous protrusion, see Figure 2 to Figure 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com