Corrugated aluminum sheath high-voltage power cable resistant to buffer layer ablation

A high-voltage power, corrugated aluminum technology, used in power cables with shielding/conducting layers, power cables, insulated cables, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

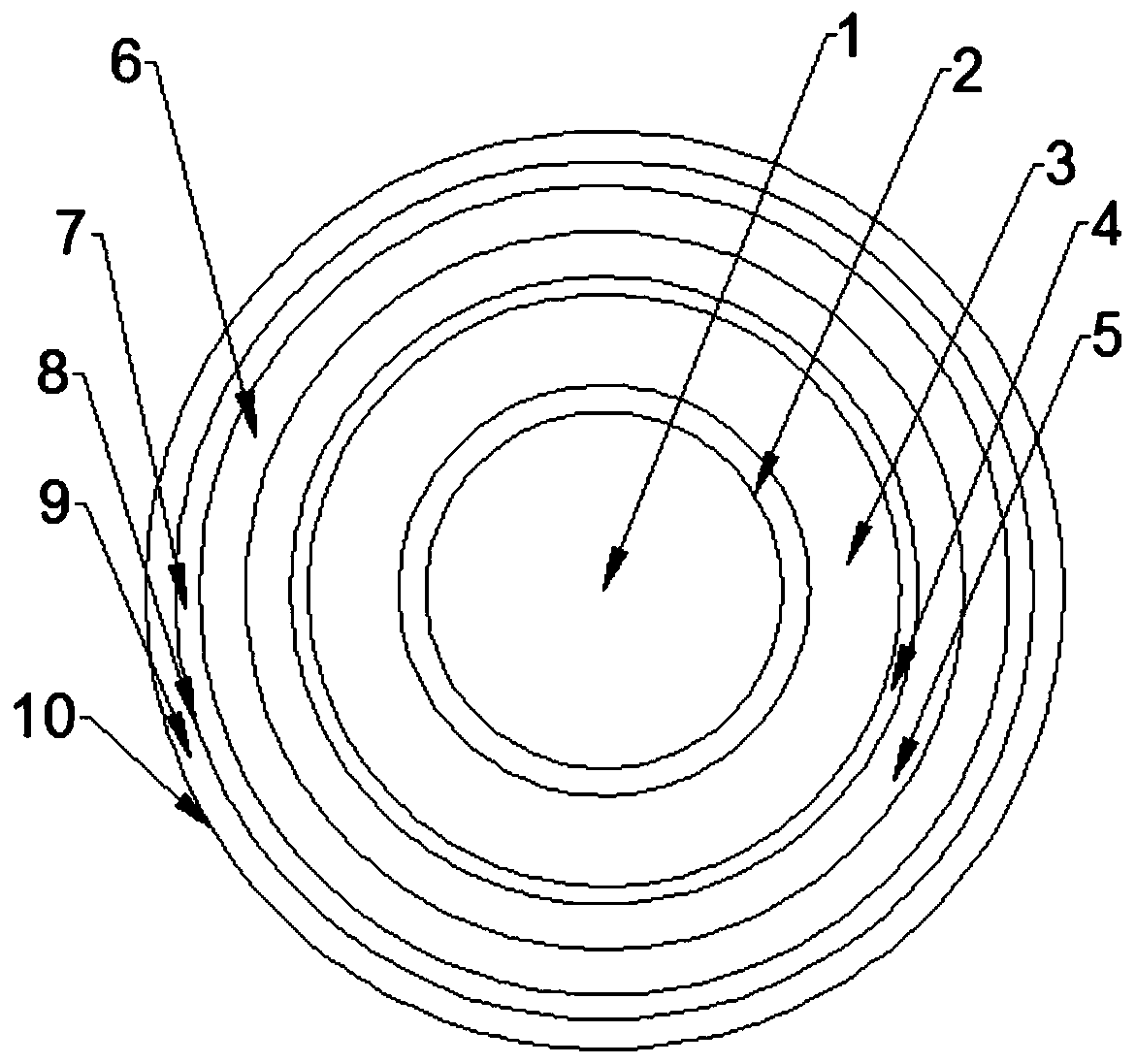

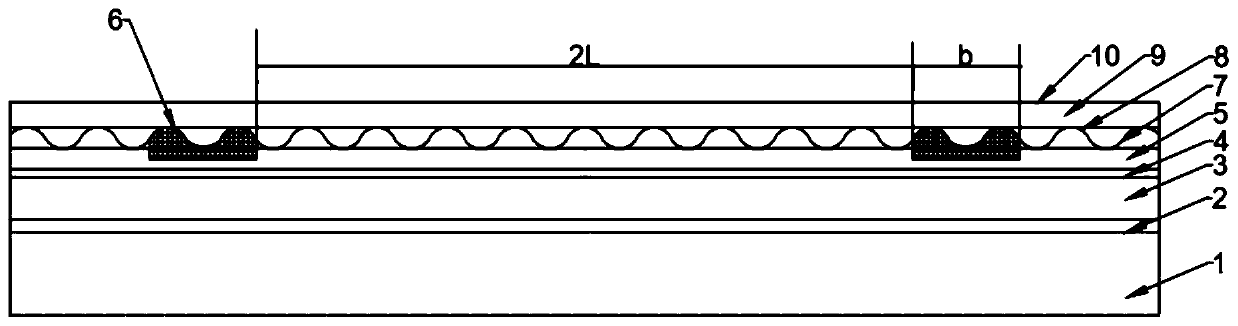

[0067] An embodiment of the present invention provides a corrugated aluminum sheathed high-voltage power cable resistant to ablation of the buffer layer, including: a conductor 1, a shielding layer 2, an insulating layer 3, an insulating shielding layer 4, and a buffer layer that are sequentially arranged on the surface of the conductor from inside to outside 5. Semi-conductive pad 6, corrugated aluminum sheath 7, anti-corrosion asphalt layer 8, non-metallic sheath 9 and graphite layer 10.

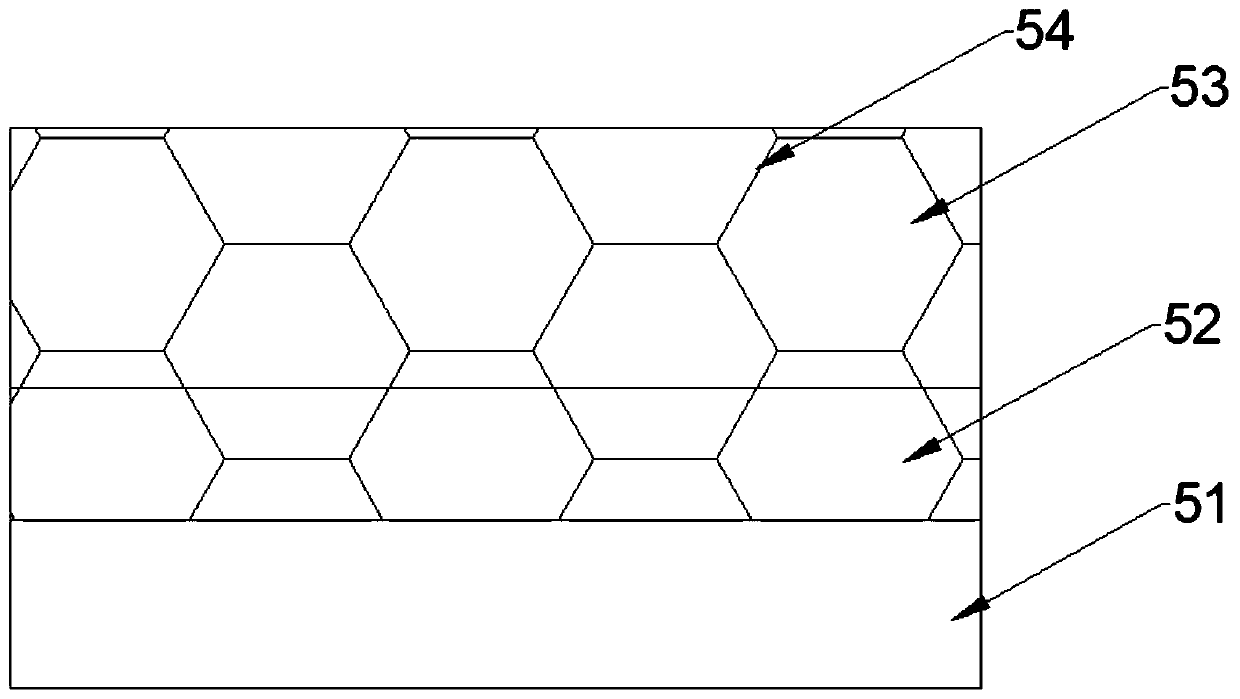

[0068] In the present embodiment, in order to realize electrical compatibility between the semiconductive spacer 6 and the cushioning layer 5, its cushioning layer 5 is made of polyester fiber nonwoven fabric 51 with conductive carbon powder, stick-coated polyacrylate expansion powder (resistor) Gouache) 52, semi-conductive fluffy cotton 53 and metal filament 54 constitute.

[0069] Wherein the metal filament 54 is intertwined between the polyester fiber non-woven fabric 51 with conductive...

Embodiment 2

[0077] On the basis of Embodiment 1, the semiconductive spacer 6 is located between the insulating shielding layer 4 and the buffer layer 5 in the cable structure in a tangential direction.

[0078] Typically, the resistivity of the insulating shielding layer 4, the semiconducting spacer 6 and the buffer layer 5 can be controlled to be 10 2 Ω·m, achieve electrical compatibility, and its buffer layer 5 can also be made of polyester fiber nonwoven fabric 51 with conductive carbon powder, sticky coated polyacrylate expansion powder (water-blocking powder) 52, and semi-conductive fluffy cotton 53 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com