Wheel tooth gap compensation method, system and controller

A backlash compensation and controller technology, applied in belts/chains/gears, transmission parts, mechanical equipment, etc., to simplify the compensation logic and improve the compensation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

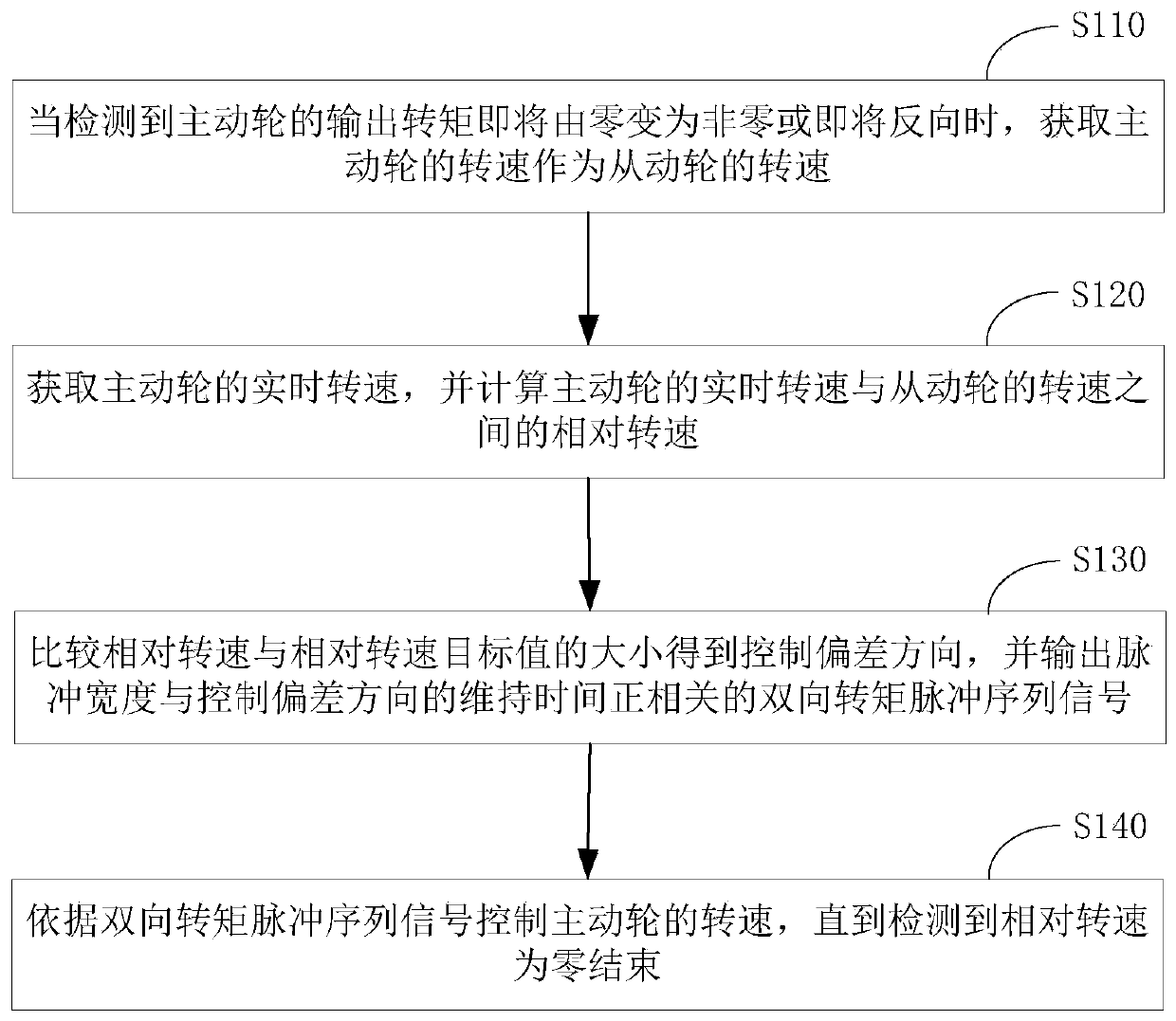

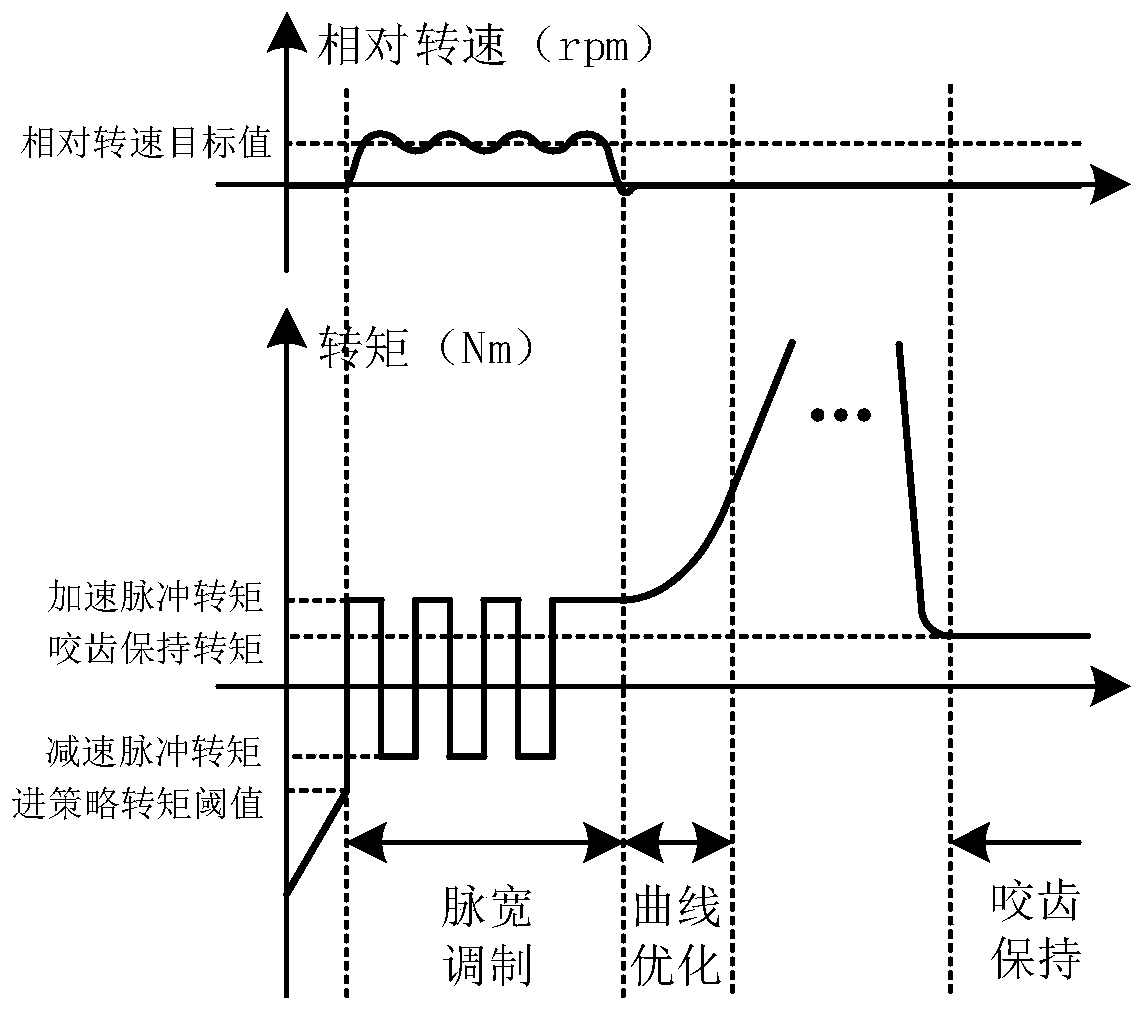

Method used

Image

Examples

Embodiment Construction

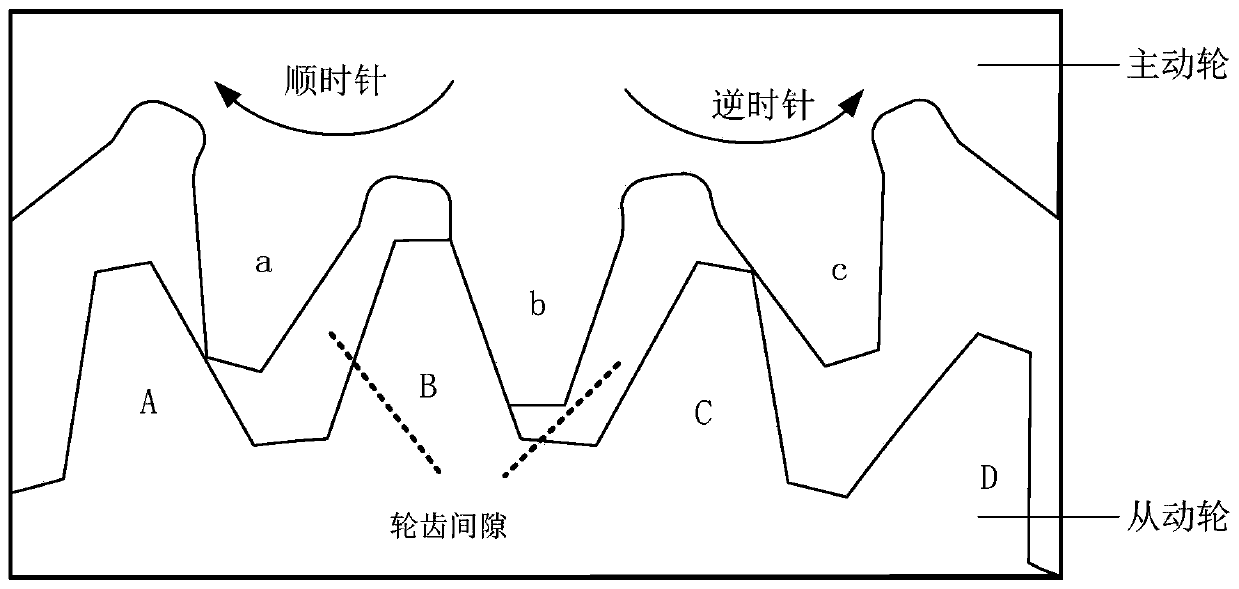

[0043] The structure of the new energy electric vehicle transmission system includes three parts: the drive motor, the gearbox, and the transmission shaft. The three parts are connected by a gear structure. Due to the existence of the gap between the teeth, when the direction of motion of the gear is reversed, it will cross the gap between the teeth and cause gnashing vibration , which in turn leads to the setback of the whole vehicle, poor comfort and driving experience.

[0044]At present, the traditional gear backlash compensation schemes are to perform torque compensation separately for different working conditions where teeth jitter occurs. Accelerator start moment; ②No bite compensation, low speed, step on the accelerator to enter the drive mode; ③No backlash compensation, low speed, release the accelerator to exit the drive mode; ④No backlash compensation, high speed, step on the accelerator, switch from feedback mode Instantaneous in driving mode; ⑤ No gear backlash co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com