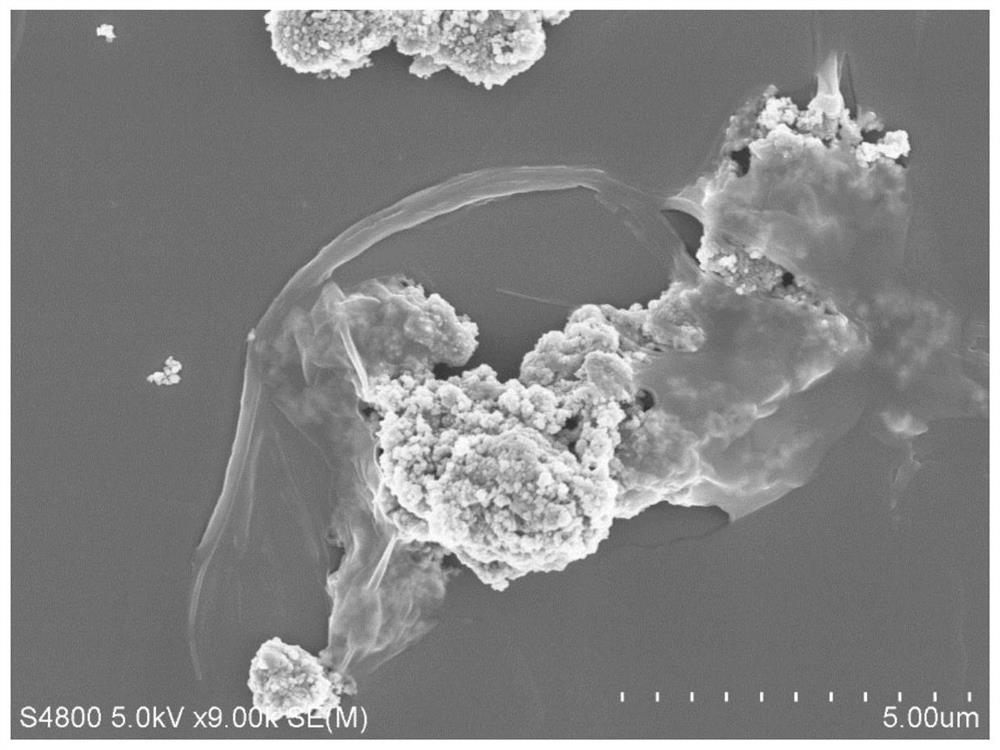

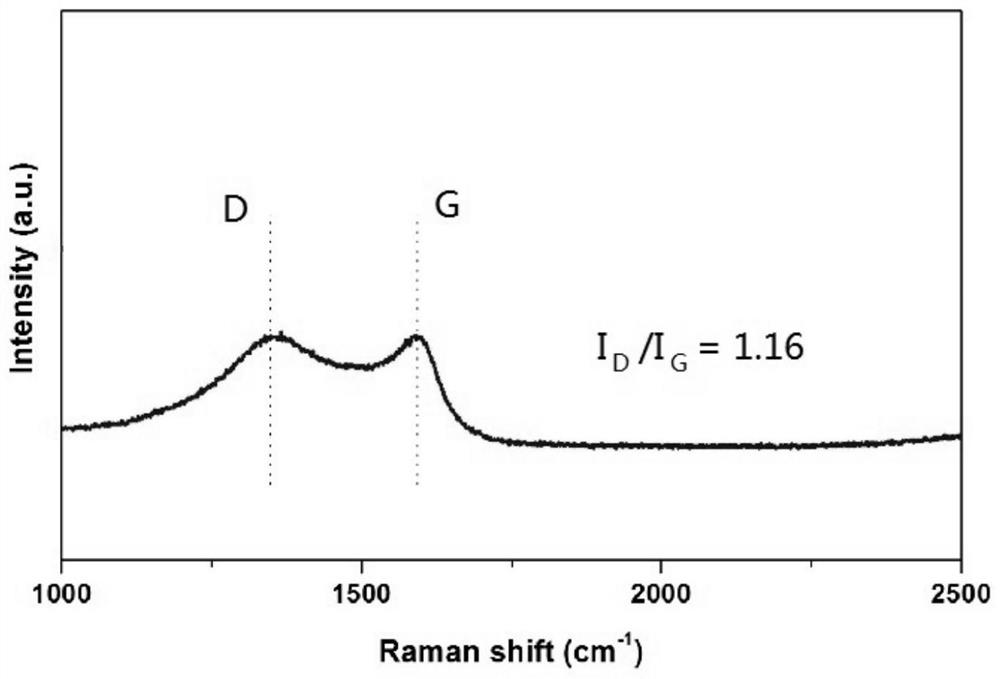

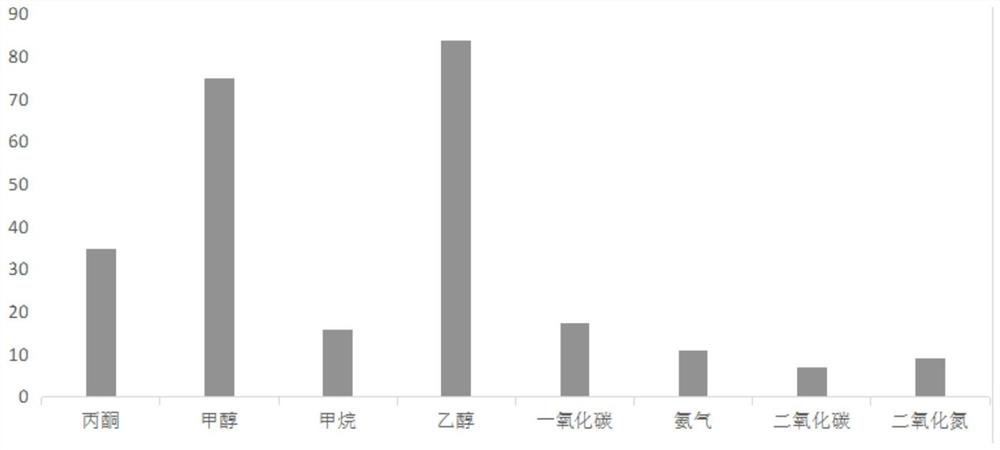

A kind of preparation method of cobalt oxide/rgo organic alcohol molecule sensitive film

A sensitive film and organic alcohol technology, applied in liquid chemical plating, metal material coating process, coating, etc., can solve problems such as poor anti-interference ability, weak selectivity, and failure to meet fine detection requirements, and achieve operational Convenience, controllability, and quick response/recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Analytical pure Co(CH 3 COO) 2 4H 2 O was fully dissolved in deionized water, and the pH value of the solution was adjusted to 2.0 with acetic acid; fully stirred for 1 hour to obtain a red transparent solution A, and the Co in the solution 2+ The concentration is 0.5mmol / mL;

[0032] 2) Uniformly disperse GO in anhydrous ethanol solvent, and perform ultrasonic treatment, specific ultrasonic conditions: frequency 30Hz, power 200W, time 30min, to obtain solution B, whose graphene oxide concentration is 0.5mg / mL;

[0033] 3) Mix solutions A and B according to the volume ratio of 1:0.2, so that graphene oxide and Co(CH 3 COO) 2 4H 2 The mass ratio of O is 1 mg: 5.0 mg to obtain a mixed solution C;

[0034] 4) Add the mixed solution C into the microwave hydrothermal reaction kettle, the filling ratio is 50%, put the pre-cleaned silicon substrate into the reaction kettle, then seal the reaction kettle, install it in the microwave hydrothermal instrument, select the ...

Embodiment 2

[0037] 1) Analytical pure Co(CH 3 COO) 2 4H 2 O was fully dissolved in deionized water, and the pH value of the solution was adjusted to 3.0 with acetic acid; fully stirred for 1 hour to obtain a red transparent solution A, and the Co in the solution 2+ The concentration is 0.6mmol / mL;

[0038] 2) Evenly disperse GO in anhydrous ethanol solvent, and perform ultrasonic treatment, specific ultrasonic conditions: frequency 30Hz, power 200W, time 30min, to obtain solution B, whose graphene oxide concentration is 1.0mg / mL;

[0039] 3) Mix solutions A and B according to the volume ratio of 1:0.2, so that graphene oxide and Co(CH 3 COO) 2 4H 2 The mass ratio of O is 1mg:10.0mg, obtains mixed solution C;

[0040] 4) Add the mixed solution C into the microwave hydrothermal reaction kettle, the filling ratio is 67%, put the pre-cleaned silicon substrate into the reaction kettle, then seal the reaction kettle, install it in the microwave hydrothermal instrument, select the control ...

Embodiment 3

[0043] 1) Analytical pure Co(CH 3 COO) 2 4H 2 O was fully dissolved in deionized water, and the pH value of the solution was adjusted to 6.0 with acetic acid; a red transparent solution A was obtained by fully stirring for 1 h, and Co in the solution 2+ The concentration is 1.2mmol / mL;

[0044] 2) Uniformly disperse GO in anhydrous ethanol solvent, and perform ultrasonic treatment. The specific ultrasonic conditions are: frequency 30Hz, power 200W, time 30min, to obtain solution B, whose graphene oxide concentration is 2.0mg / mL;

[0045] 3) Mix solution A and B according to the volume ratio of 1:1.5, so that graphene oxide and Co(CH 3 COO) 2 4H 2 The mass ratio of O is 1mg: 12.0mg, and the mixed solution C is obtained;

[0046] 4) Add the mixed solution C into the microwave hydrothermal reaction kettle, the filling ratio is 30%, put the pre-cleaned silicon substrate into the reaction kettle, then seal the reaction kettle, install it in the microwave hydrothermal instrume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com