Method and system for concentrating high-salt mine well water

A mine water and high-salt technology, applied in mining wastewater treatment, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as high investment and operating costs, low concentration ratio, high pressure resistance coefficient requirements, etc., to save The effect of investment and operating costs, prolonging the service life of membranes, and reducing fouling and fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

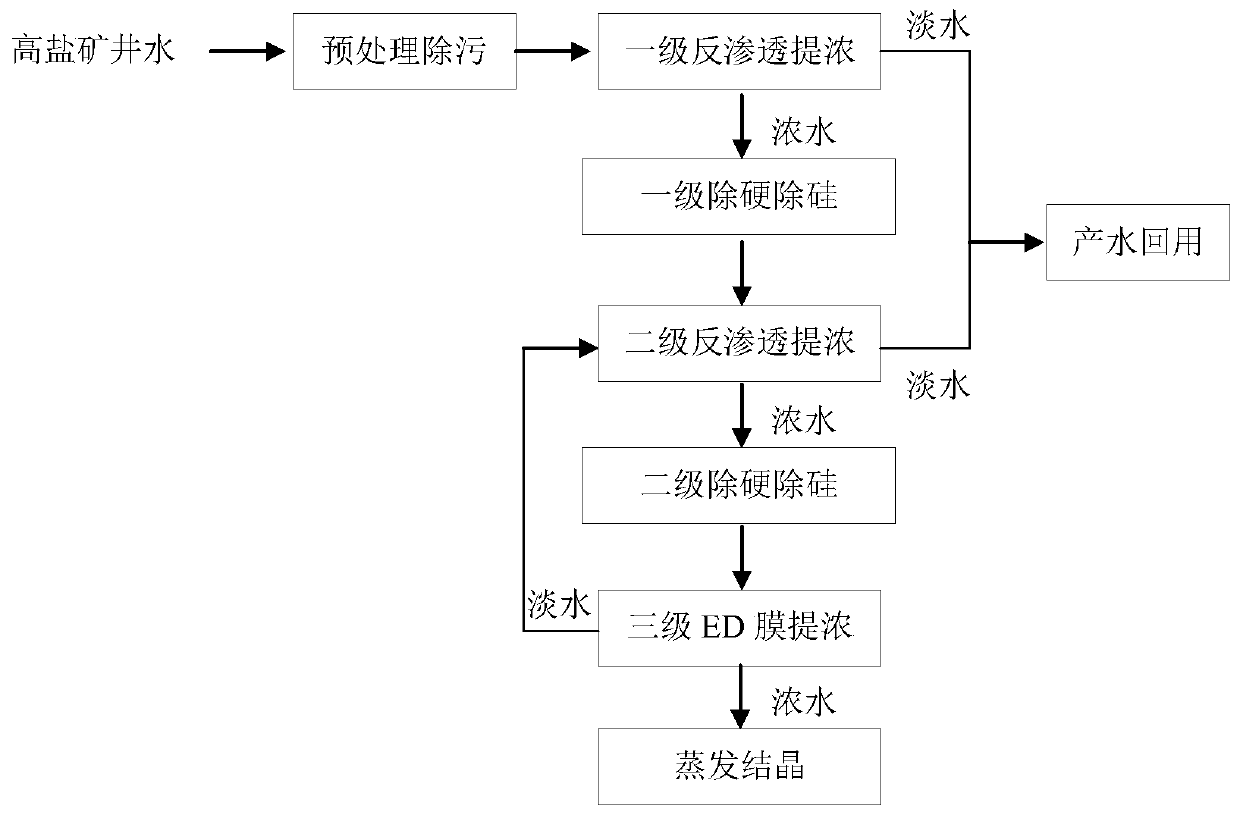

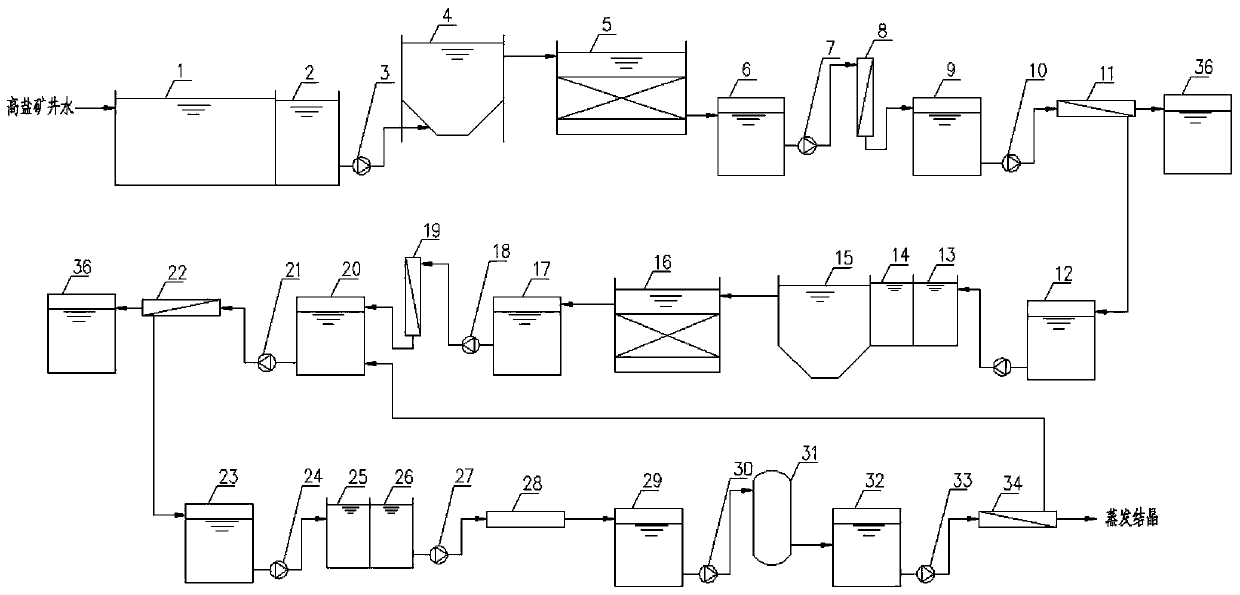

[0050] The core of the present invention is to provide a method for enriching high-salt mine water. The process flow diagram of a specific implementation is shown in figure 1 , Which is called the first embodiment, the method includes the following steps:

[0051] (1) Pretreatment and decontamination: Mine water first enters the pretreatment system, and PAC and PAM are added to the pretreatment system to remove oil and suspended solids in the water;

[0052] (2) First-level reverse osmosis enrichment: the effluent of step (1) is pumped into the first-level reverse osmosis system, the TDS in the water is concentrated to 10-20g / L, and the produced water is reused;

[0053] (3) Primary hardening and silicon removal: The concentrated water produced in step (2) is sent to the primary hardening and silicon removal system to remove most of the calcium, magnesium and silicon ions in the water, reducing membrane fouling pollution;

[0054] (4) Secondary reverse osmosis enrichment: send the effl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com