Preparation process of multi-layer composite automobile leather

A multi-layer compounding and preparation technology, applied in lamination, coating, layered products, etc., can solve the problems of no barrier protection, easy to be sunburned, leather aging, etc., to increase protection and sun protection, Good sun protection performance, the effect of improving anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

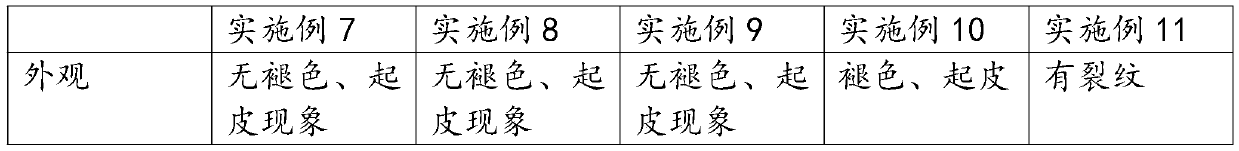

Examples

Embodiment 1

[0031] see figure 1 Shown, the preparation method of sunscreen is:

[0032] S1. Add 0.23mol 2-amidinoacetate methyl ester hydrochloride, 10mmol sodium tert-butoxide and 1L solvent dioxane into the reaction kettle, replace the air in the reaction kettle with nitrogen gas, and add 0.1mol o-hydroxyl Benzaldehyde, heat up to 105°C and reflux while stirring, and continue to reflux for 2.5-3h. After the reaction, cool to room temperature, use a rotary evaporator to remove the solvent, and separate and purify by column chromatography. The chromatographic solution is petroleum ether: dichloro Methane: ethyl acetate = 10:1:3, to obtain intermediate A;

[0033] S2, the intermediate A prepared in step S1, 0.22mol 1-(2-pyrimidinyl)-4-hydroxypiperidine, 20g catalyst (sulfamic acid: zirconium tungstate mass ratio=4:1) and 1L solvent Add toluene into the reaction kettle, feed nitrogen to replace the air in the reaction kettle, raise the temperature to 115°C and reflux, and continue the ref...

Embodiment 2

[0036] The sunscreen lotion includes the following raw materials by weight: 7g of acrylate, 5g of fatty alcohol polyoxyethylene ether, 2g of sodium acetate, 1g of olive oil, 7g of sunscreen, 8g of polydimethylsiloxane, 20g of propylene glycol, and 100g of deionized water;

[0037] The preparation method of sunscreen lotion is:

[0038] (1) Add acrylate, fatty alcohol polyoxyethylene ether, sodium acetate, and deionized water into a mixer and stir to obtain A emulsion;

[0039] (2) Olive oil, sunscreen, propylene glycol are joined in another blender and stirred evenly to obtain B emulsion;

[0040] (3) Place emulsion A in a water bath at a temperature of 40°C, and add emulsion B to emulsion A dropwise while stirring. After the dropwise addition, cool down to 30°C and continue stirring for 5 hours to obtain a sunscreen emulsion.

Embodiment 3

[0042] The sunscreen lotion includes the following raw materials by weight: acrylate 10g, fatty alcohol polyoxyethylene ether 4g, sodium acetate 1.5g, olive oil 2g, sunscreen 9.5g, polydimethylsiloxane 7g, propylene glycol 25g, deionized water 100g ;

[0043] The preparation method of sunscreen lotion is:

[0044] (1) Add acrylate, fatty alcohol polyoxyethylene ether, sodium acetate, and deionized water into a mixer and stir to obtain A emulsion;

[0045] (2) Olive oil, sunscreen, propylene glycol are joined in another blender and stirred evenly to obtain B emulsion;

[0046](3) Place emulsion A in a water bath at a temperature of 45°C, and add emulsion B to emulsion A dropwise while stirring. After the dropwise addition, cool down to 30°C and continue stirring for 5 hours to obtain a sunscreen emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com