Novel foaming forming die

A foam molding, a new type of technology, applied in the field of new foam molding molds, can solve the problems of product surface defects, easy deformation and blockage of air grooves, and easy roughening of product surfaces, etc., to achieve reasonable structure, shorten cooling time, and improve surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

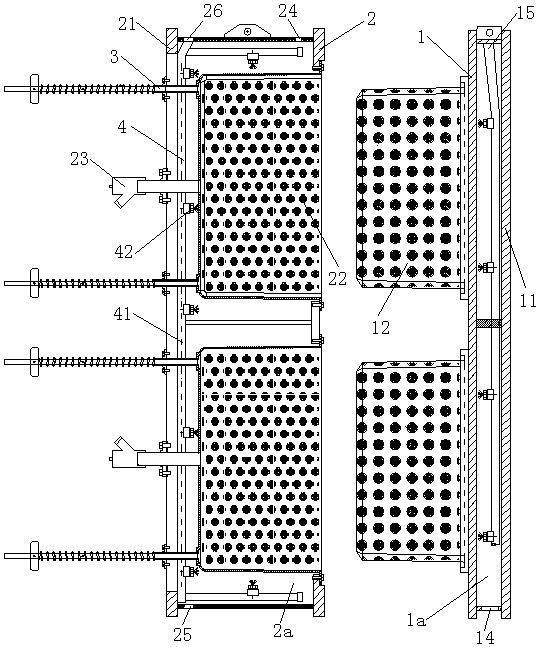

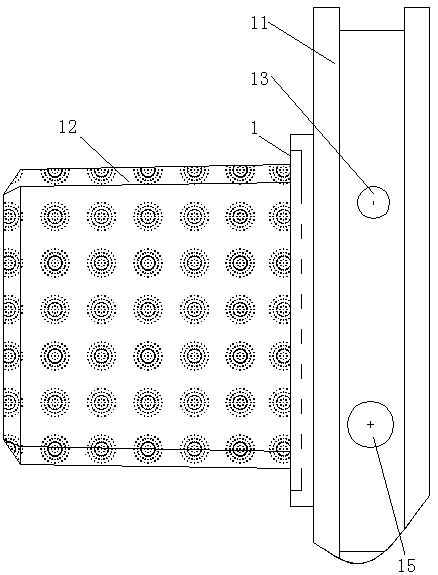

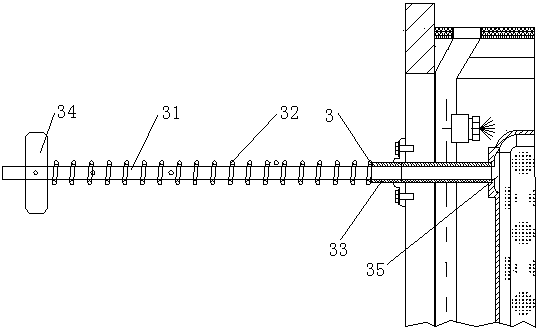

[0014] Refer to attached figure 1 , attached figure 2 , attached image 3 , a new foam molding mold of the present invention, it is made up of punch 1, die 2, demoulding mechanism 3, cooling device 4, and demoulding mechanism 3 is arranged on the die 2, and described punch 1 is made up of The punch jacket 11 and the punch core 12 are composed of the punch jacket 11 and the punch core 12 to form an air chamber I1a, and the punch jacket 11 is respectively provided with an air inlet 13, an air outlet 14, and a water inlet 15; The die 2 described above is composed of a die coat 21 and a die core 22. The die coat 21 and the die core 22 form an air chamber II 2a, and the die coat 21 is respectively provided with a feed port 23 and an air inlet. 24. The air outlet 25, the water inlet 26, and the cooling device 4 are arranged in the air chamber I1a and the air chamber II2a; the punch core 12 and the die core 22 are bent and welded with 2mm-6mm stainless steel plates Form, and be v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com