Treatment process and treatment device for high-concentration hydrogen sulfide gas

A gas treatment and hydrogen sulfide technology, applied in gas treatment, combined device, combustible gas purification, etc., can solve problems such as personal safety threats to staff, long production shutdown and recovery period, and secondary air pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

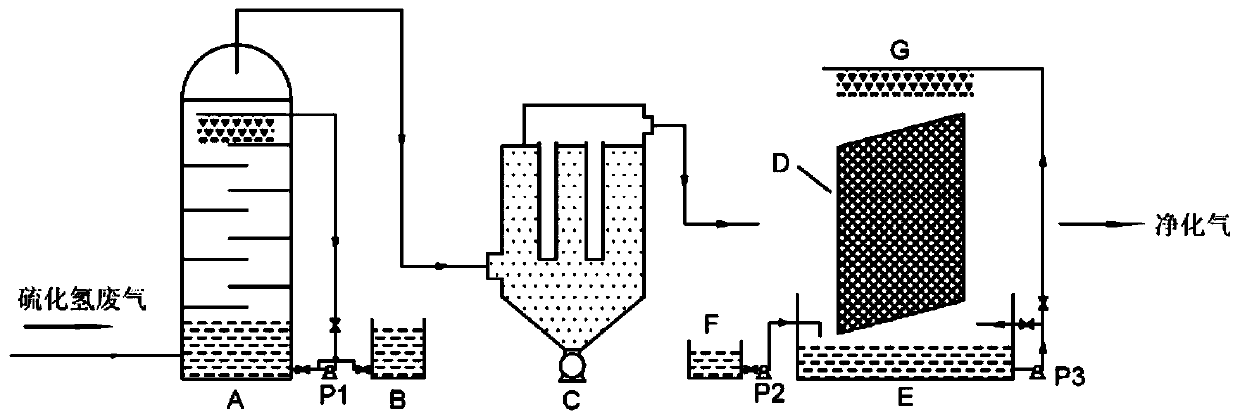

[0070] The hydrogen sulfide concentration in the hydrogen sulfide exhaust gas is 200ppm. After the gas is sprayed with 5% (mass fraction) hydrogen peroxide, the hydrogen sulfide concentration drops to 20ppm. The gas enters the ion exchange fiber purification unit after passing through the dust removal device.

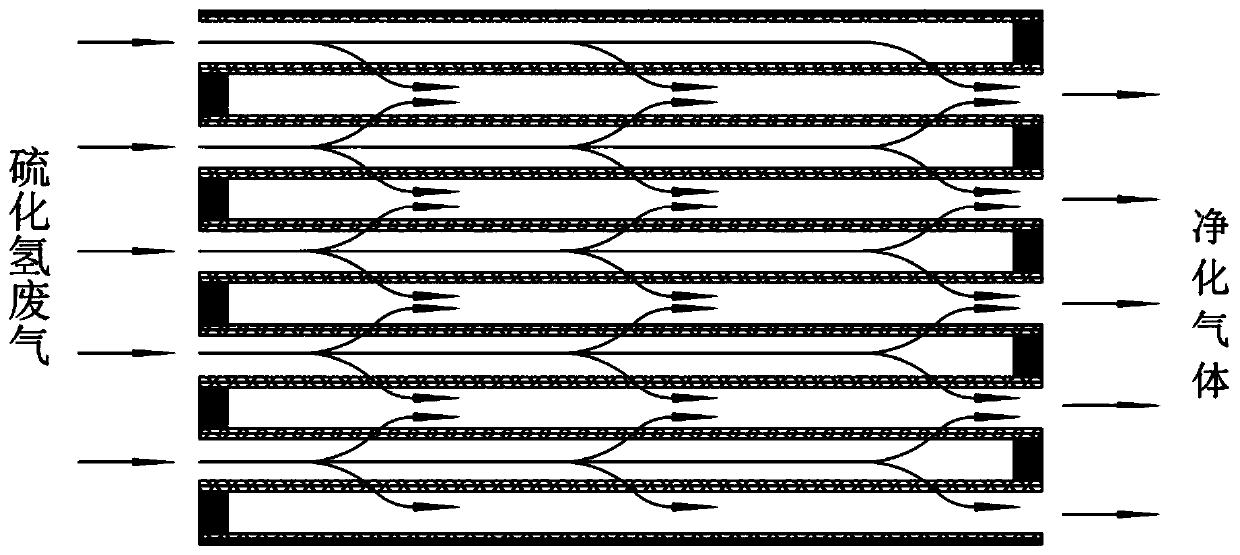

[0071] The filter layer is purified by ion-exchange fibers whose surface functional groups are amine groups, and the air volume is controlled at 1000m 3 / h, the wind speed of gas passing through the purification filter layer is 5m / min. Within 25 minutes after the start of adsorption, the concentration of purified gas was detected to be 0ppm; turn on the regeneration solution spray pump, and spray 3% sodium carbonate solution for regeneration for 3 minutes; Add hydrogen peroxide, reflux and stir for 15 minutes; after repeating this 15 times, the concentration of purified gas remains at 0ppm after testing, and the concentration of hydrogen sulfide in the air above the sat...

Embodiment 2

[0074] The hydrogen sulfide concentration in the hydrogen sulfide waste gas is 500ppm. After the gas is sprayed with 20% (mass fraction) hydrogen peroxide, the hydrogen sulfide concentration drops to 70ppm. The gas enters the ion exchange fiber purification unit after passing through the dust removal device.

[0075] The filter layer is purified by ion-exchange fibers whose surface functional groups are amine groups, and the air volume is controlled at 500m 3 / h, the wind speed of gas passing through the purification filter layer is 2.5m / min. Within 20 minutes after the start of adsorption, the concentration of purified gas was detected to be 0ppm; turn on the regeneration solution spray pump, and spray 5% sodium hydroxide solution for regeneration for 1 minute; 1 Add hydrogen peroxide, reflux and stir for 15 minutes; after repeating this 15 times, the concentration of purified gas remains at 0ppm after testing, and the concentration of hydrogen sulfide in the air above the sa...

Embodiment 3

[0078] The hydrogen sulfide concentration in the hydrogen sulfide waste gas is 1000ppm. After the gas is sprayed with 10% (mass fraction) hydrogen peroxide, the hydrogen sulfide concentration drops to 50ppm. The gas enters the ion exchange fiber purification unit after passing through the dust removal device.

[0079] The filter layer is purified by ion-exchange fibers whose surface functional groups are amine groups, and the air volume is controlled at 100m 3 / h, the wind speed of gas passing through the purification filter layer is 0.5m / min. Within 30 minutes after the start of adsorption, the concentration of purified gas was detected to be 0 ppm; turn on the regeneration solution spray pump, and spray 0.5% sodium hydroxide solution for regeneration for 5 minutes; 1 Add hydrogen peroxide, reflux and stir for 20 minutes; after repeating this 15 times, the concentration of purified gas remains at 0ppm after testing, and the concentration of hydrogen sulfide in the air above t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com