Firework water method production process

A production process and water method technology, applied in the directions of fireworks, offensive equipment, weapon types, etc., can solve the problems of deteriorating the production environment of enterprises, explosions, and easy burning, and achieve the goal of improving the production environment, ensuring personal safety, and improving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

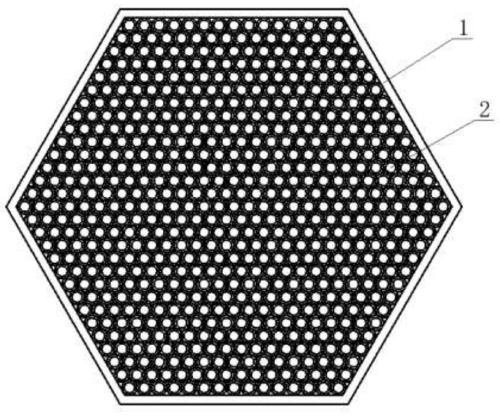

[0019] The invention provides a water method production process of fireworks, such as figure 1 shown, including the following steps:

[0020] Provide an oxidizing agent, a reducing agent, and a firecracker cake basket 1 with one end open. Several cartridges 2 are arranged inside the firecracker cake basket 1. A lead wire is placed in each cartridge 2 and the end of the lead wire extends beyond the mouth of the cartridge 2. First, uniformly mix the oxidizing agent and the reducing agent to prepare the mixed drug, then uniformly mix the mixed drug with an appropriate amount of water to make it soak, and finally fill the soaked mixed drug into each cartridge 2.

[0021] Further, the fireworks water method production process also includes the following steps:

[0022] The hydroso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com