Method for preparing phenol or alkylphenol from methoxyphenol compounds

A technology of methoxyphenol and alkylphenol, which is applied in the field of high-value utilization of biomass, can solve the problems such as the separation and utilization of by-product methanol, which are rarely involved in research, the ability to reach 65 bar, and the difficulty of product separation and purification, so as to achieve price stability. High efficiency, good application prospects, and high utilization of reactive atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

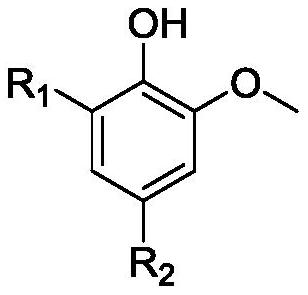

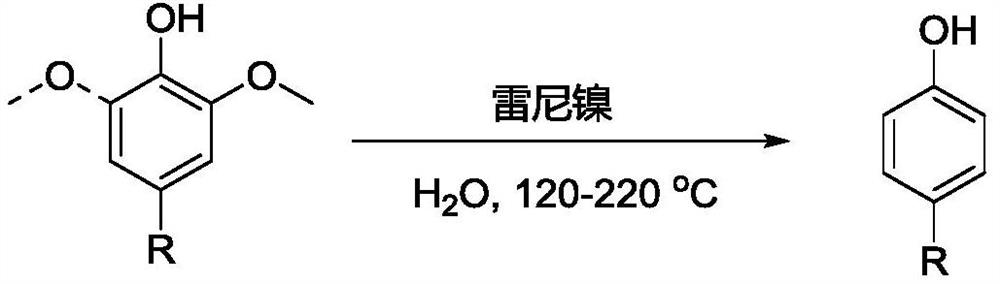

[0027] The present invention proposes a kind of preparation method of phenol or alkylphenol, it comprises the following steps:

[0028] The methoxyphenol compound reacts in the water phase at a temperature of 120-220° C. under the condition of Raney nickel catalyst to obtain a solution containing phenol or alkylphenol; the product is separated.

[0029]

[0030] The invention discloses a method for preparing alkylphenol by selective catalytic conversion and demethoxylization of methoxyphenol compounds. In the method, the methoxy phenol compound is heated in an aqueous solution in the presence of a Raney nickel catalyst to remove the methoxy group to prepare an alkyl phenol. The catalyst used in the present invention is a cheap Raney nickel catalyst, which has a wide range of applications in industry, and avoids the defect that the reaction in the prior art must be reacted under an expensive, complex preparation method supported metal catalyst , has a very good cost advanta...

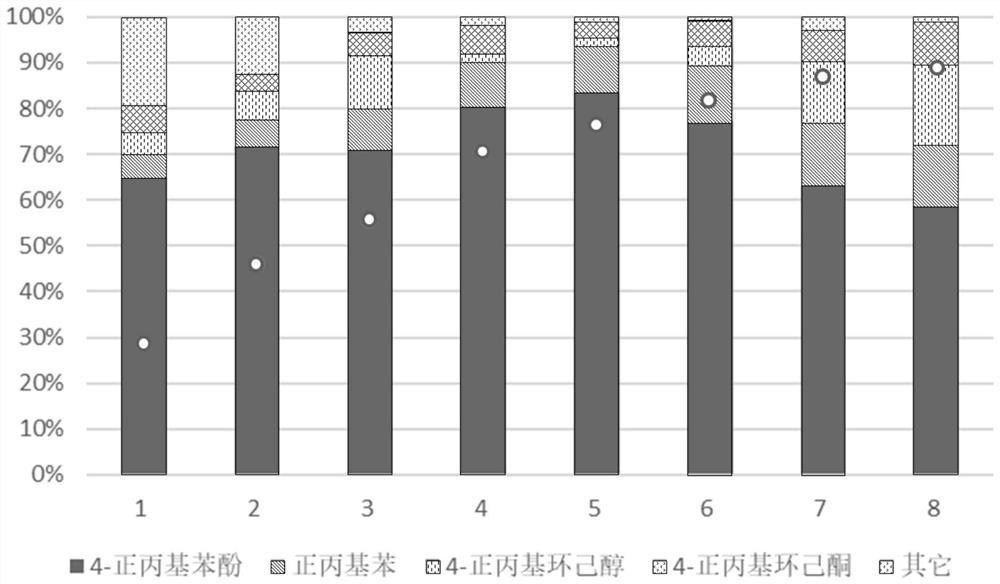

Embodiment 1

[0059] Different types of Raney nickel catalysts catalyzed the conversion of 2-methoxy-4-n-propylphenol to 4-n-propylphenol by selective demethoxylation. Specific steps are as follows:

[0060] Take by weighing raw material 2-methoxy-4-n-propylphenol 0.5mmol, Raney nickel catalyst 0.1 gram, water 3ml, join in the stainless steel reactor of 10ml, heat reactor to required temperature (in the present embodiment The reaction temperature is 180° C.), and after the reaction is completed (the reaction time is controlled to be 6 h), the reaction kettle is cooled to room temperature.

[0061] The catalyst was held by a magnet, the reaction solution was poured into a separatory funnel, and extracted with ethyl acetate (3×10ml). The extracted solution was added with 20ul of n-dodecane as an internal standard, and then analyzed by gas chromatography.

[0062] Gas chromatographic analysis conditions: GC6890 gas chromatograph, FID detector, capillary column (HP-5, 30m×0.250mm×0.25μm), take...

Embodiment 2

[0070] Selective demethoxylation of 2-methoxy-4-n-propyl phenol over Raney nickel catalysts to prepare 4-n-propyl phenol in different solvent systems. Specific steps are as follows:

[0071] Weigh raw material 2-methoxy-4-n-propylphenol 0.5mmol, Raney-4200 Raney nickel catalyst 0.1 gram, solvent 3ml, join in the stainless steel reactor of 10ml, heat reactor to required temperature (this implementation The reaction temperature in the example is 180° C.), and after the reaction is finished (the reaction time is controlled to be 6 hours), the reaction kettle is cooled to room temperature.

[0072] If water is used as solvent, then utilize magnet to hold catalyzer, reaction solution is poured in separatory funnel, by ethyl acetate (3 * 10ml) extraction, the solution after extraction adds 20ul n-dodecane as internal standard, Analysis is then performed by gas chromatography. If it is a reaction system with other organic solvents, remove the supernatant liquid after the reaction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com