Self-rescue winch suitable for industrial vehicle

A technology for industrial vehicles and winches, applied in the field of self-rescue winches, can solve the problems of increasing production costs, troubles, and inability to travel, and achieve the effects of improving the scope of application, simple positioning effect, and improving use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

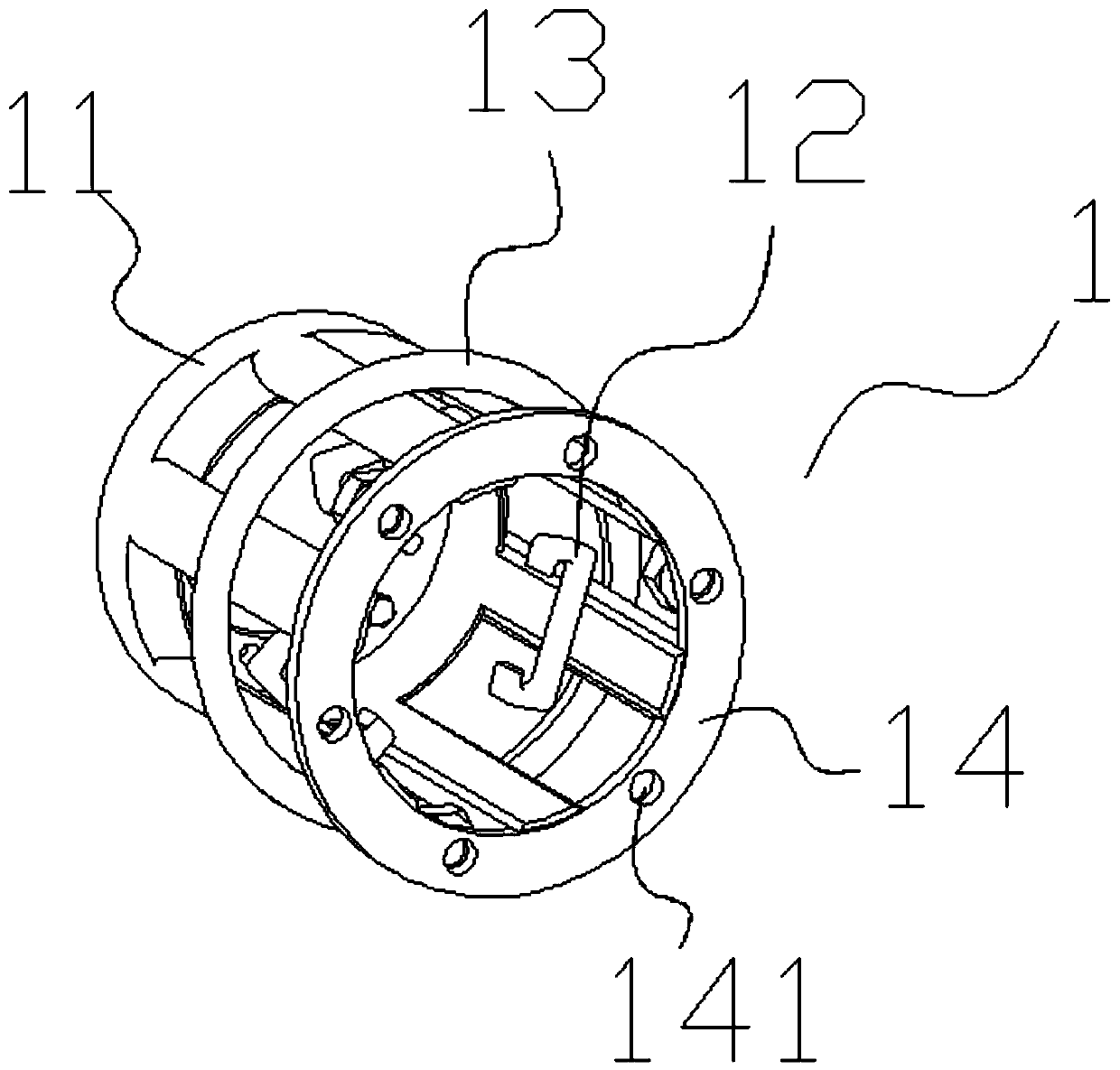

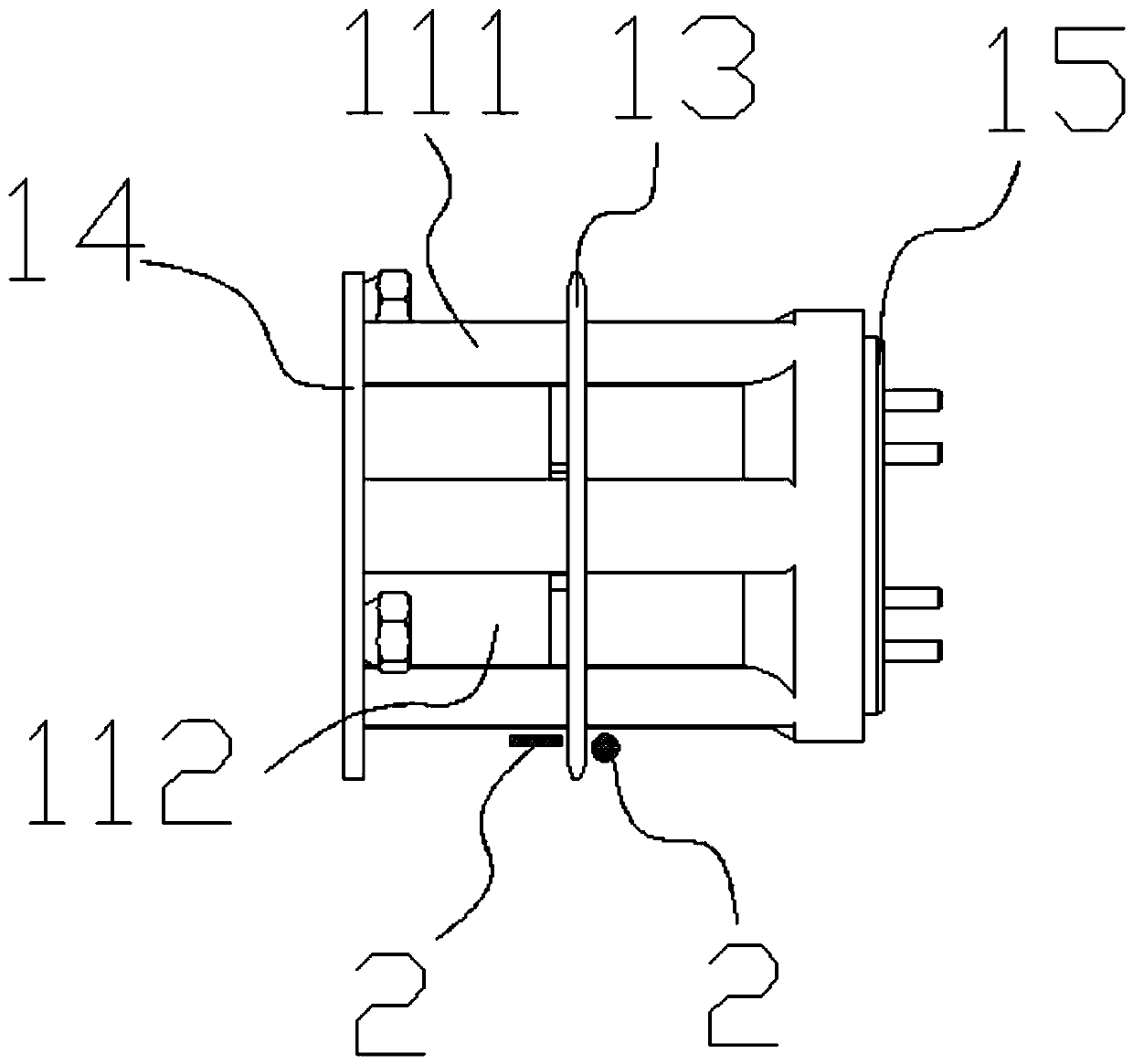

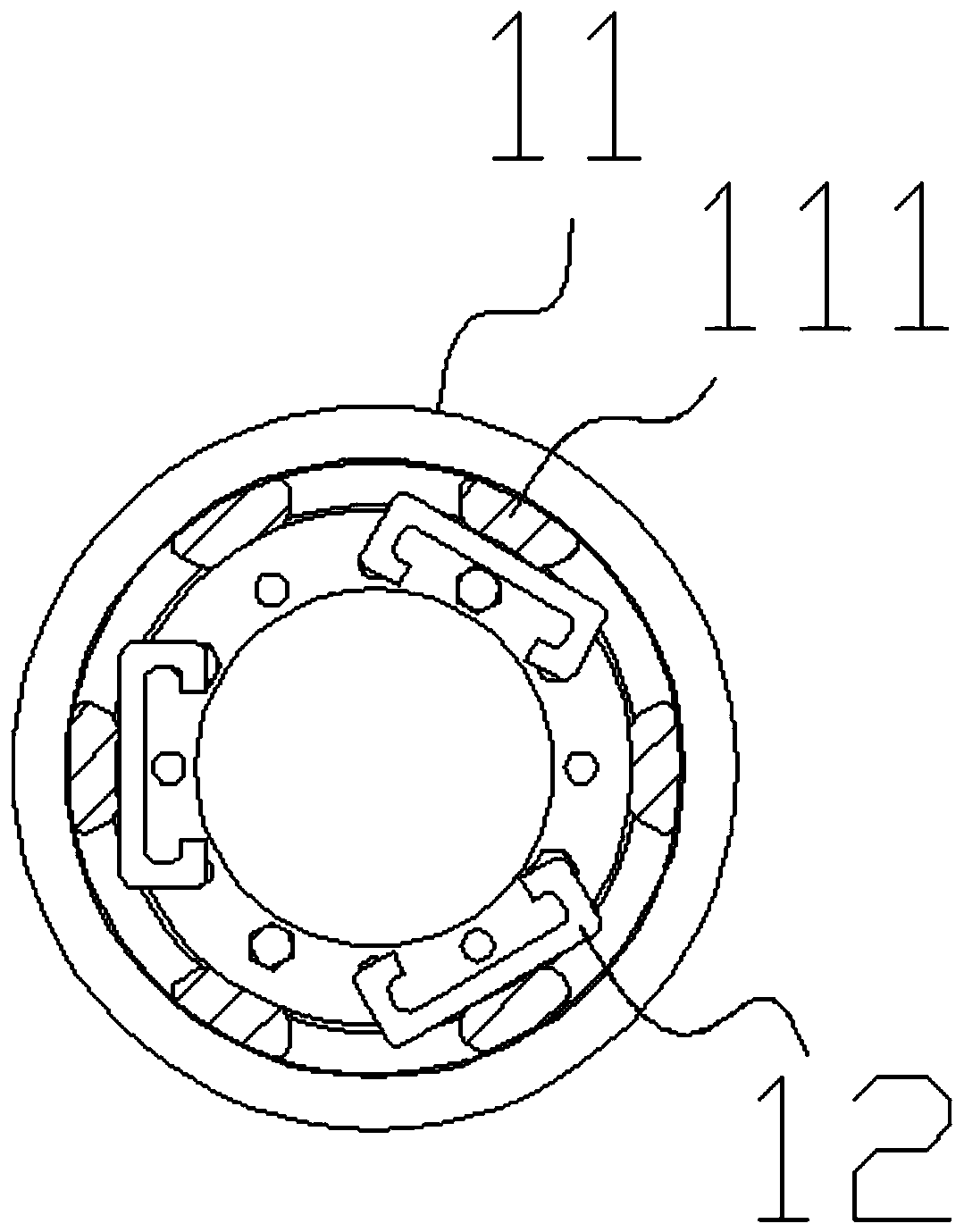

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] like Figure 1-7 A self-rescue winch suitable for industrial vehicles is shown, the self-rescue winch is installed at the axial end face of the vehicle hub 3, and the end face of the wheel hub 3 includes a hub installation disk surface 31 and a wheel hub installation disk surface 31 end surface. The half-shaft end cover 32, this kind of self-rescue winch makes the winch body 1 have the function of selectively assembling on the end face of the hub mounting plate 31 or the end face of the half-shaft end cover 32 by adopting a two-way assembly scheme, and at the same time combines the winch body 1 The structural optimization realizes the functions of light weight and easy hooking of the winch. The specific structure is as follows:

[0027] The self-rescue winch includes a winch body 1, one end of the winch body 1 is provided with an assembly surface 14 for being fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com