An automatic distribution method for ore bins

A technology of automatic material distributing and ore silo, which is applied in the direction of transportation, packaging, loading/unloading, etc., and can solve the problems of low feeding efficiency, low feeding efficiency of cloth trolley, low feeding accuracy of silo, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] This implementation discloses an automatic material distribution system for mine bins.

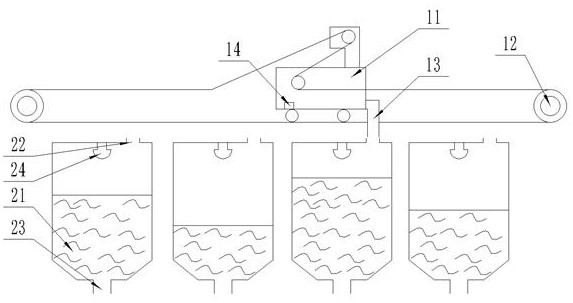

[0056] Such as figure 1 Shown: a kind of automatic distributing system that is used for ore bin, comprises a plurality of bins 21 (comprising four bins 21 in the present embodiment), also includes:

[0057] The silo 21 monitoring unit is used to obtain the material height of each silo 21 in real time;

[0058] The distributing trolley 11 unit includes the distributing trolley 11 for feeding materials to each silo 21, and the trolley monitoring component for obtaining the current position of the distributing trolley 11;

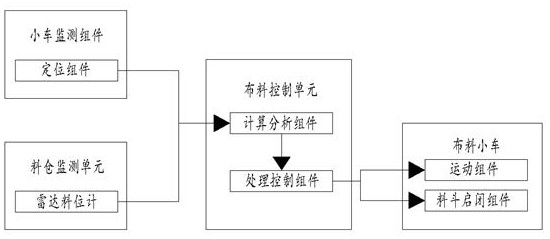

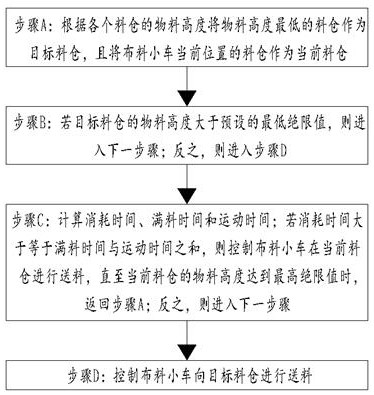

[0059] The material distribution control unit is used to control the direction of the material distribution trolley 11 according to the material height of each silo 21 and the current position of the distribution trolley 11, as well as the preset material consumption speed of each silo 21, the feeding speed and the movement speed of the fabric trolley 11. Correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com