NON-PVC base material type 3D printed floor and preparation method thereof

A NON-PVC, 3D printing technology, applied in the direction of chemical instruments and methods, wood layered products, lamination, etc., can solve the problems of detachment of polyolefin base layer and easy warping of solid wood layer, so as to enhance the connection force and ensure Background color, the effect of ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

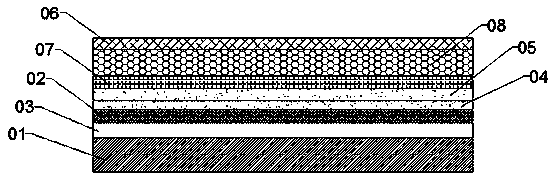

[0048] A kind of NON-PVC base material 3D printing floor, its structure is as attached figure 1 As shown, it includes a NON-PVC substrate layer 01, a balance layer 03, a solid wood layer 02, a UV primer layer 04, a UV white paint layer 05, and a pattern layer 07, which are sequentially arranged on the NON-PVC substrate layer 01. , concave-convex effect layer 08, UV topcoat layer 06.

[0049] The thickness of the NON-PVC substrate layer 01 is equivalent to the thickness of the conventional floor substrate layer, and the thickness of the balance layer is preferably 95 microns to 115 microns, and in this embodiment, it is further preferably 105 microns. The thickness of the solid wood layer 02 is preferably 0.1 cm-0.3 cm, and 0.3 cm is selected in this embodiment. The thicknesses of the UV primer layer 04 and the UV white paint layer 05 are equivalent, preferably 40 microns to 60 microns, preferably 55 microns in this embodiment.

[0050] The NON-PVC substrate layer 01 is mainl...

Embodiment 2

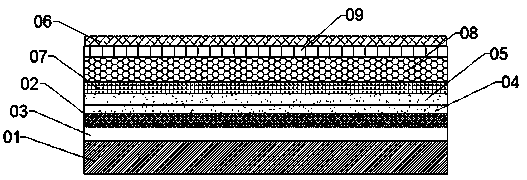

[0058] A kind of NON-PVC base material 3D printing floor, its structure is as attached figure 2 As shown, it includes a NON-PVC substrate layer 01, a balance layer 03, a solid wood layer 02, a UV primer layer 04, a UV white paint layer 05, and a pattern layer 07, which are sequentially arranged on the NON-PVC substrate layer 01. , Concave-convex effect layer 08, UV wear-resistant paint layer 09, UV topcoat layer 06. The thickness of the NON-PVC substrate layer 01 is equivalent to that of the conventional floor substrate layer, and the thickness of the balance layer is 100 microns. The thickness of solid wood layer 02 is 0.2cm. The thickness of the UV primer layer 04 and the UV white paint layer 05 is equivalent, which is 40 microns.

[0059] The NON-PVC substrate layer 01 is mainly composed of PP+wood powder, and the preparation method of the substrate layer 01 is as follows:

[0060] (1) 300 parts by weight of wood powder and 500 parts by weight of PP powder were mixed an...

Embodiment 3

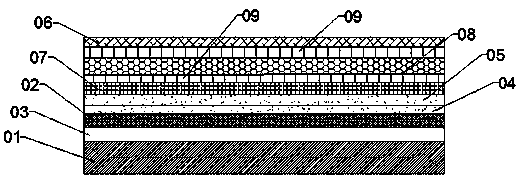

[0068] A kind of NON-PVC base material 3D printing floor, its structure is as attached image 3 As shown, it includes a NON-PVC substrate layer 01, a balance layer 03, a solid wood layer 02, a UV primer layer 04, a UV white paint layer 05, and a pattern layer 07, which are sequentially arranged on the NON-PVC substrate layer 01. , UV wear-resistant paint layer 09, concave-convex effect layer 08, UV wear-resistant paint layer 09, UV topcoat layer 06.

[0069] The NON-PVC substrate layer 01 is mainly composed of high-density PE+wood powder, and the preparation method of the substrate layer 01 is as follows:

[0070] (1) 300 parts by weight of wood powder and 400 parts by weight of PP powder were mixed and pre-plasticized to obtain wood-plastic mixed powder;

[0071] (2) Put the obtained wood-plastic mixed powder into an extruder, and extrude the wood-plastic mixed powder through a die to form a plate shape, and obtain the NON-PVC substrate layer 01.

[0072] Floor preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com