Device facilitating disassembly and assembly of strut and operation method thereof

A technology of screw rod and action, applied in the field of devices that facilitate the disassembly and assembly of struts, can solve the problems of inconvenient disassembly and assembly of mechanical springs, and achieve the effect of ensuring operation efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

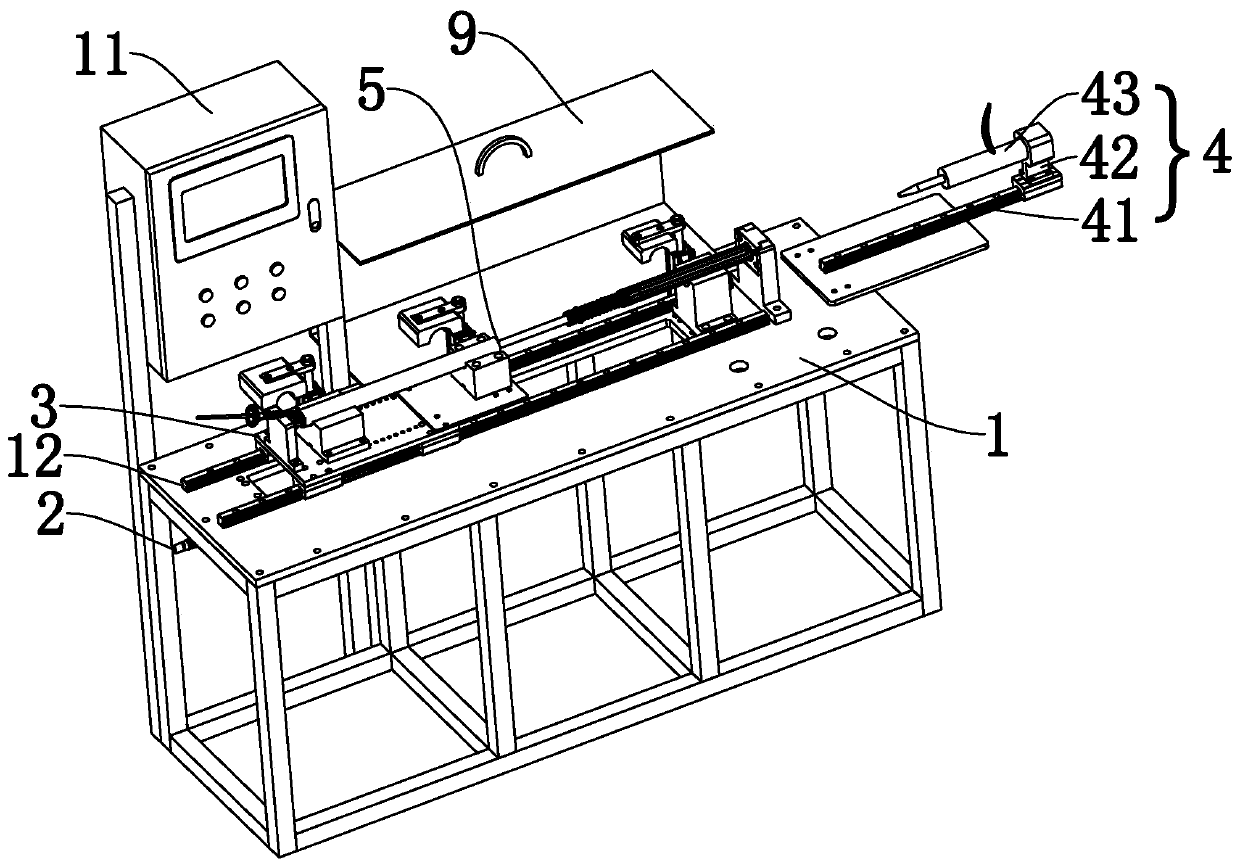

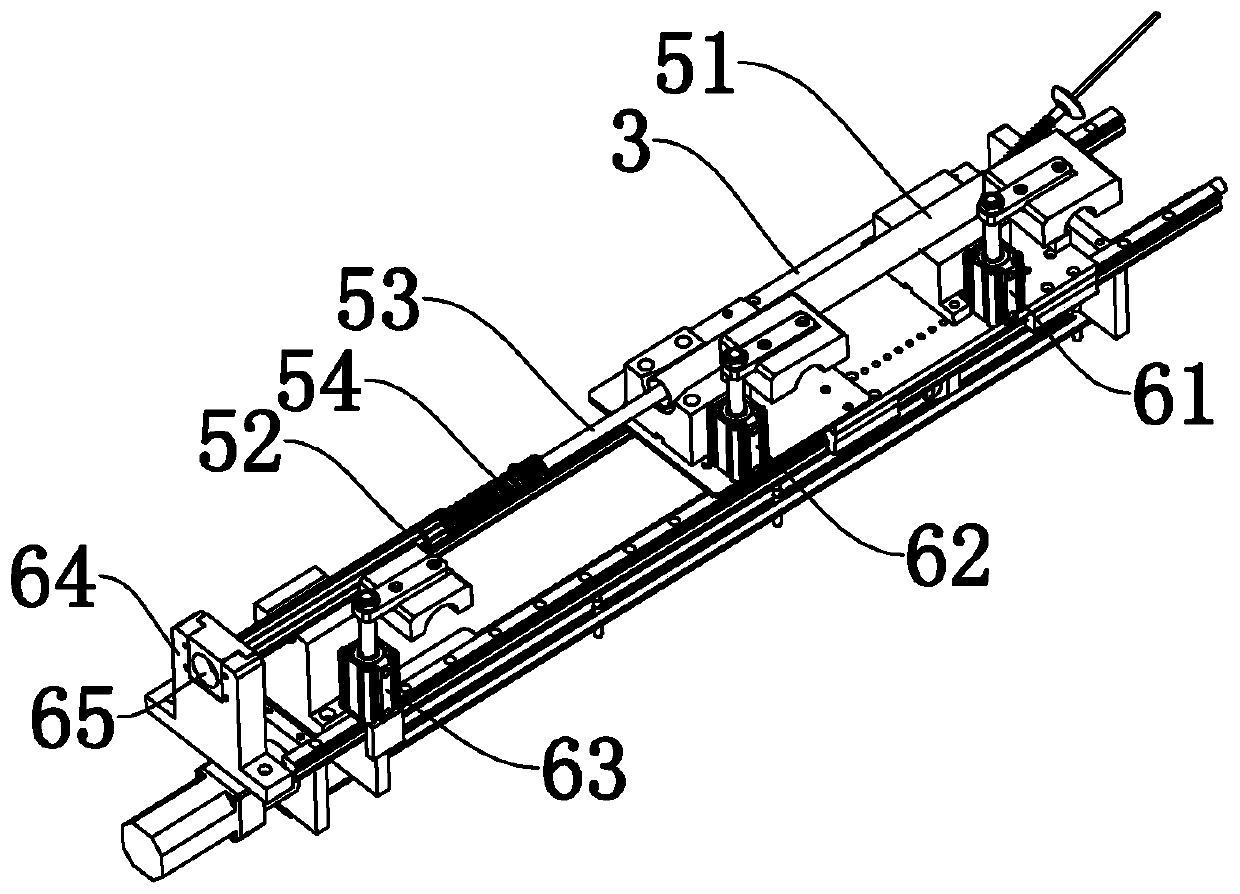

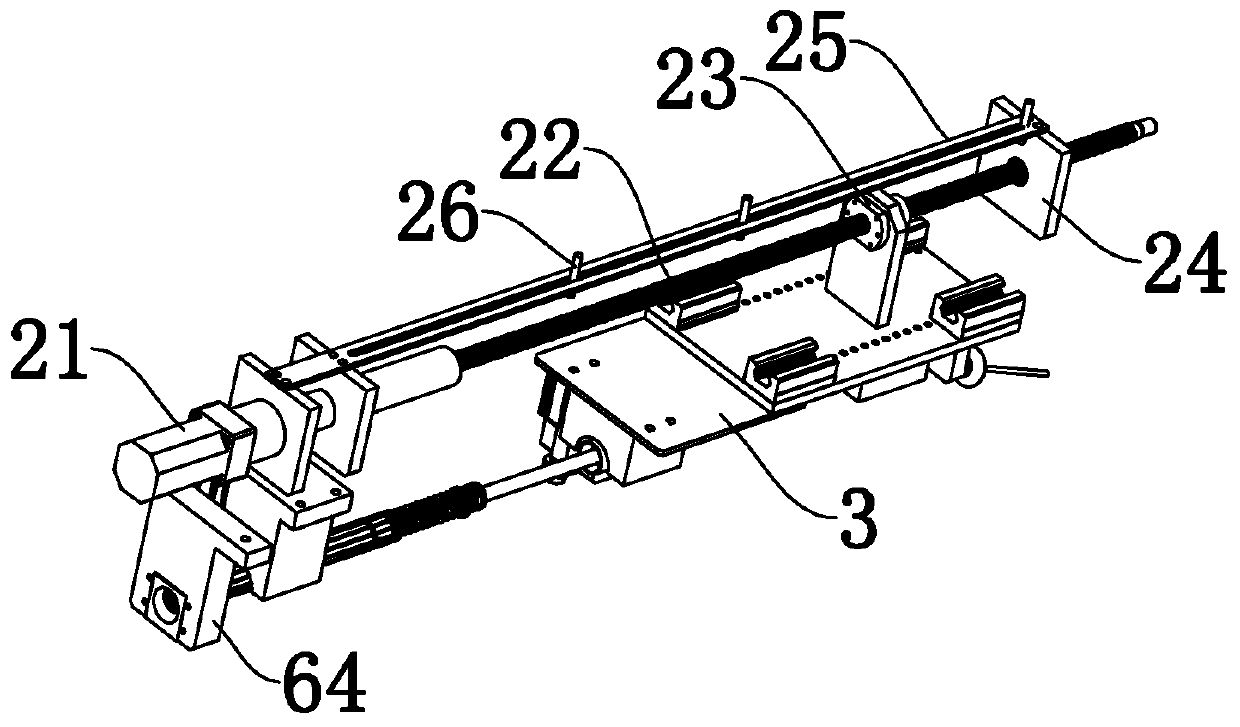

[0043] refer to Figure 1 to Figure 4 As shown in , the device provided in this embodiment to facilitate the disassembly and assembly of the strut is used to disassemble the strut 5, and the strut 5 includes an outer sleeve 51, a spring sleeve 52, and a screw sleeve that are integrated from the outside to the inside. Tube 53, and the mechanical spring 54 sleeved on the outside of the screw sleeve 53 is housed in the spring sleeve 52, and one end of the screw sleeve 53 is connected with a ball socket. The above-mentioned devices include:

[0044] Workbench 1;

[0045] The sliding seat 3 is horizontally movable and installed on the workbench 1, and a mounting position for placing the strut 5 is formed on the sliding seat 3;

[0046] The driving assembly 2 is connected to the sliding seat 3 by transmission at the power output end, so as to drive the sliding seat 3 to move horizontally;

[0047] The first clamp 61 and the second clamp 62 are installed on the sliding seat 3 respe...

Embodiment 2

[0060] This embodiment provides a working method based on the above-mentioned device for facilitating disassembly and assembly of the strut, including a disassembly process and an assembly process, wherein the disassembly process includes:

[0061] Step 1, put the outer sleeve 51 of the strut 5 into the mounting position of the first clamp 61 and the second clamp 62, put the spring sleeve 52 of the strut 5 into the mounting position of the third clamp 63, and drive the first The first clamp 61, the second clamp 62 and the third clamp 63 act and clamp the strut 5;

[0062] Step 2, the drive assembly 2 runs, driving the sliding seat 3, the first clamp 61, the second clamp 62 and the strut 5 to move backward synchronously until the screw sleeve 53 and the ball socket of the strut 5 protrude independently The through hole 65 of the fourth jig 64;

[0063] Step 3, release the thread fit between the ball socket and the screw sleeve 53;

[0064] Step 4, the driving assembly 2 conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com