3D printing quality computer online monitoring method

A 3D printing and computer technology, applied in the field of 3D printing, can solve the problems of uneven powder mixing and discharge, increased misjudgment ratio, error, etc., and achieve the effect of uniform temperature field, less sintering defects, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

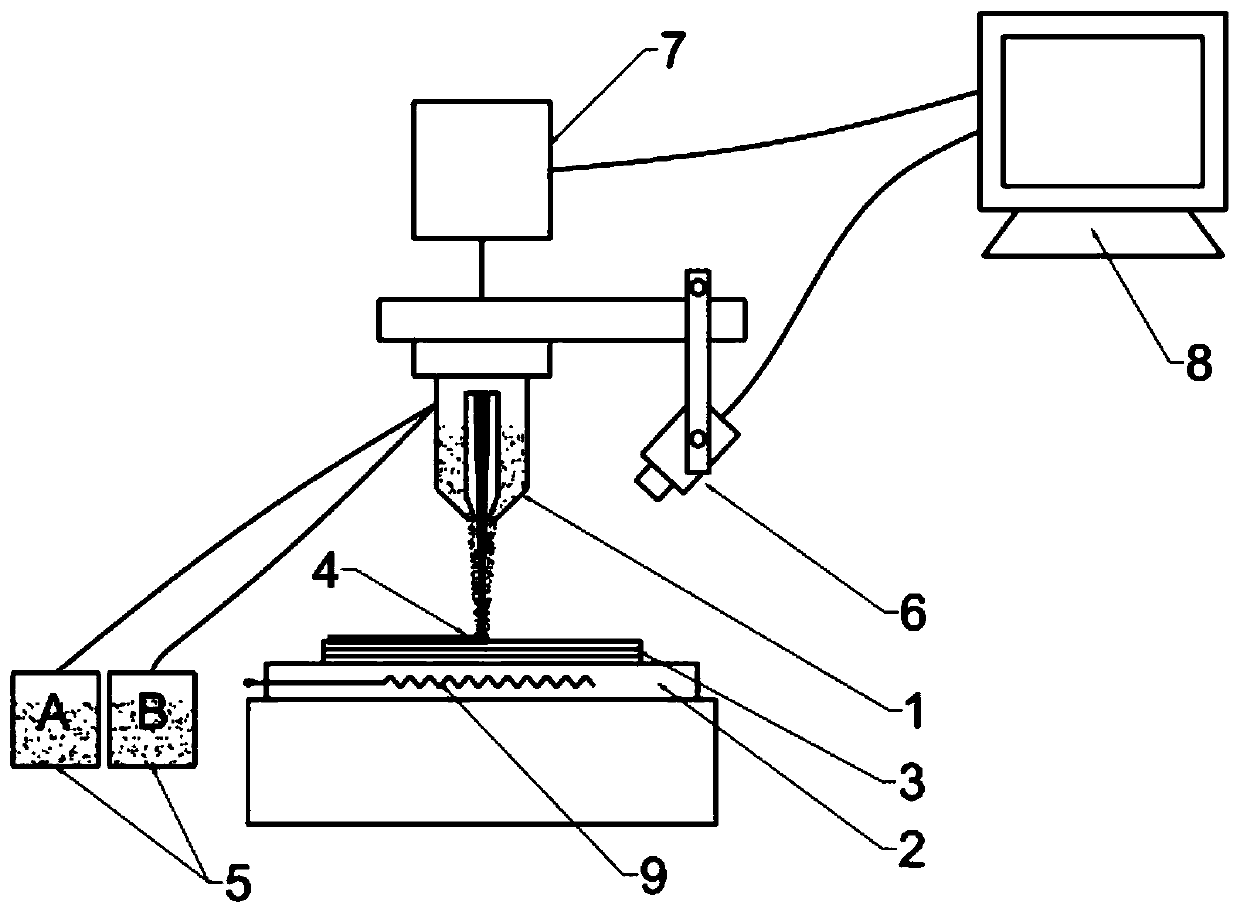

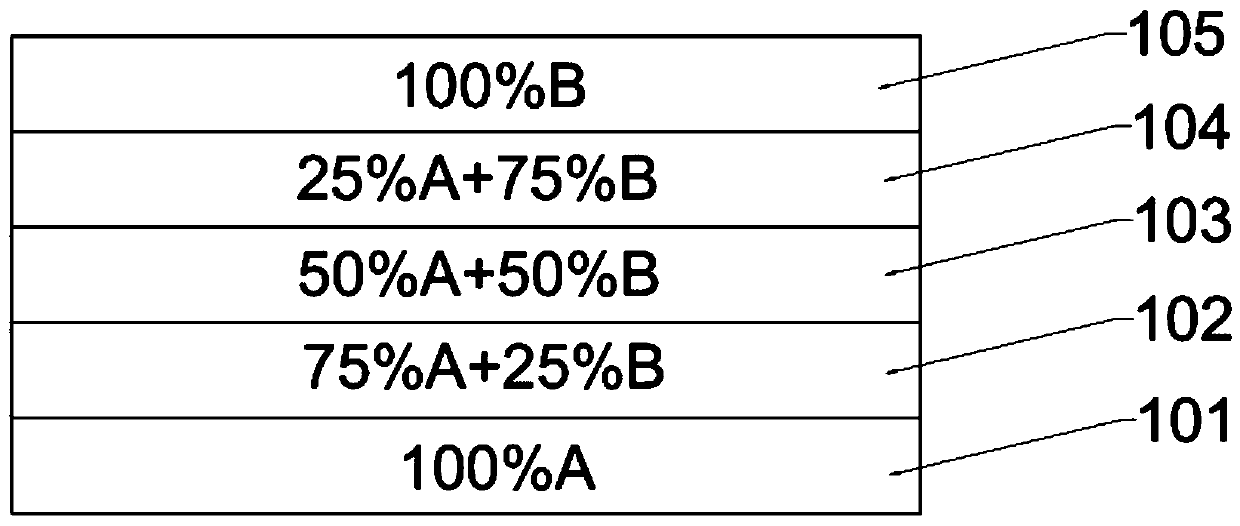

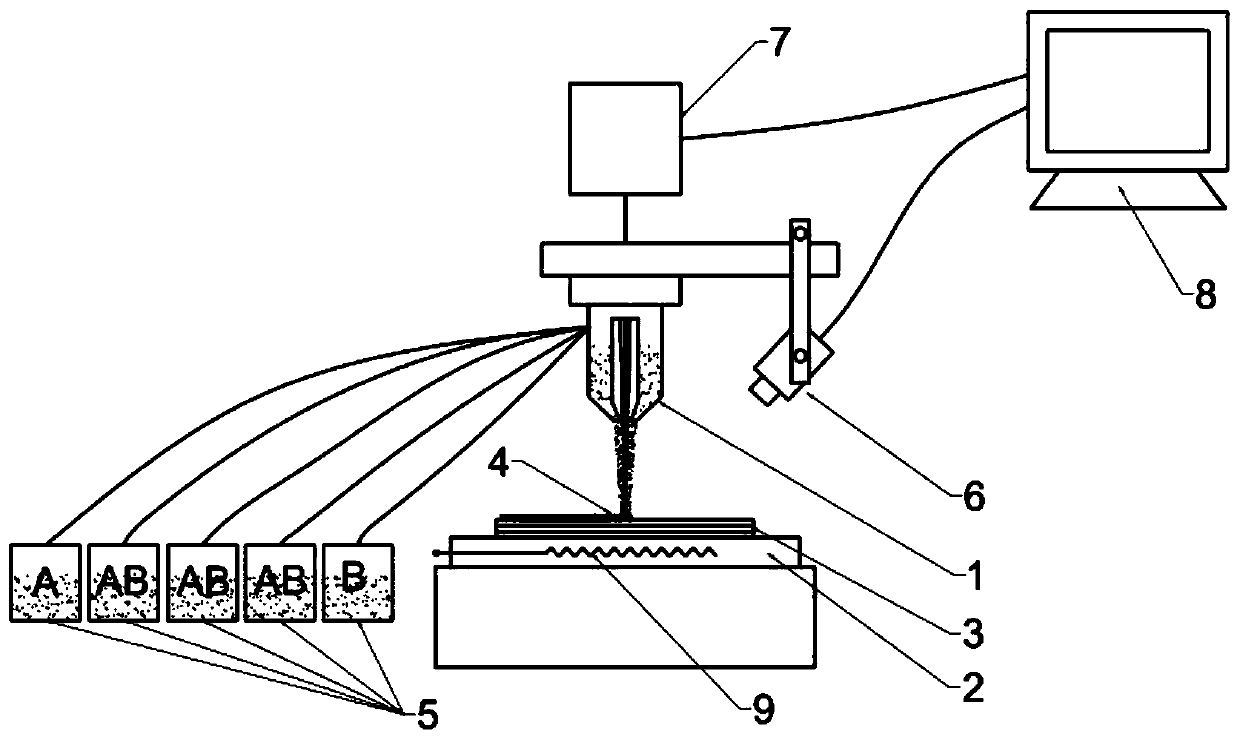

[0033] A computer online monitoring method for 3D printing quality, such as figure 1 In the shown process of laser 3D printing using multi-element powder synchronous feeding in different cylinders, the CCD camera 6 is used to collect the temperature data of the laser melting pool 4 in real time and upload it to the computer 8, which is compared with the standard temperature data pre-stored by the computer 8 and adjusted in real time Working parameters, multi-element powder synchronous powder feeding laser 3D printing is used to construct gradient functional materials, because the composition of metal elements changes, and the laser processing energy is mainly used to heat the metal powder to melt or sinter the metal powder, so When the gradient of the metal element composition changes greatly, the laser processing energy generally also changes according to the metal element composition of the current gradient layer. Therefore, the working parameters here mainly refer to the las...

Embodiment 2

[0045] To collect standard temperature data in the simulated state, the most important thing is to ensure that the simulated state is highly consistent with the actual printing parameter conditions, printing atmosphere conditions, and component heat-affected conditions in the multi-element powder synchronous powder feeding laser 3D printing. The main control printing parameters can be precisely controlled. When the printing atmosphere changes greatly, it can also be automatically adjusted by external interference. However, the formation of the heat-affected conditions of the components is passive. On the one hand, the use of high-energy laser beam forming Parts, the real-time temperature of the whole part, especially the temperature of the just completed part, is an important influencing factor. In addition to the laser energy directly irradiated to the molten pool, the temperature of the key parts of the part has the greatest influence on the cladding quality, especially for sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com