Intelligent automatic plate cleaning machine

A board cleaning machine and driven wheel technology, applied to the cleaning method using tools, cleaning methods using liquid, dryers, etc., can solve the inconvenient drying of boards, inconvenient dust cleaning on the board surface, and inconvenient waste liquid Filtering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

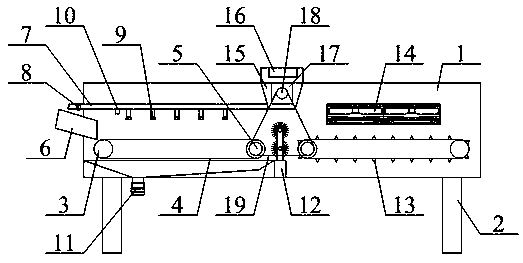

[0041] as attached figure 1 And attached image 3 shown

[0042]The present invention provides an intelligent automatic plate cleaning machine, which includes a fixed outer frame 1, a longitudinal leg 2, a left conveying roller 3, a left conveying belt 4, a left driven wheel 5, an introduction frame 6, a horizontal water conveying pipe 7, an electromagnetic Valve 8, nozzle 9, sensor 10, waste filter discharge frame structure 11, cleaning frame structure 12, prop up conveying frame structure 13, drying frame structure 14, protective cover 15, controller 16, driving motor 17, driving wheel 18 and Transmission belt 19, four longitudinal legs 2 are provided, and the bolts of the longitudinal legs 2 are installed at the lower four corners of the fixed outer frame 1; two left conveying rollers 3 are provided, and the The left conveying roller 3 is pivotally connected to the left side and the middle position of the middle position of the fixed outer frame 1; the left conveying belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com