Damper manufacturing method using auxiliary materials to assist impregnation

A manufacturing method and auxiliary material technology, applied in the field of elastic wave manufacturing, can solve problems such as vibration imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

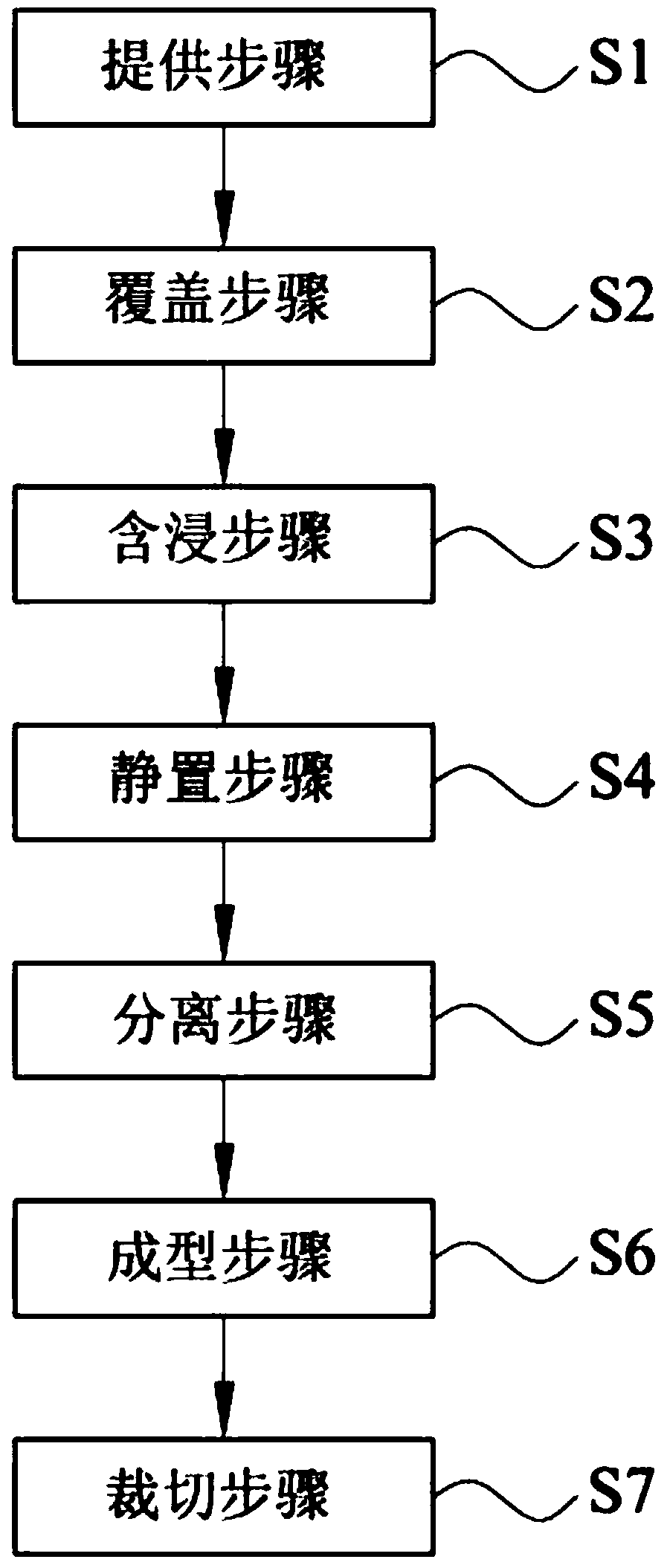

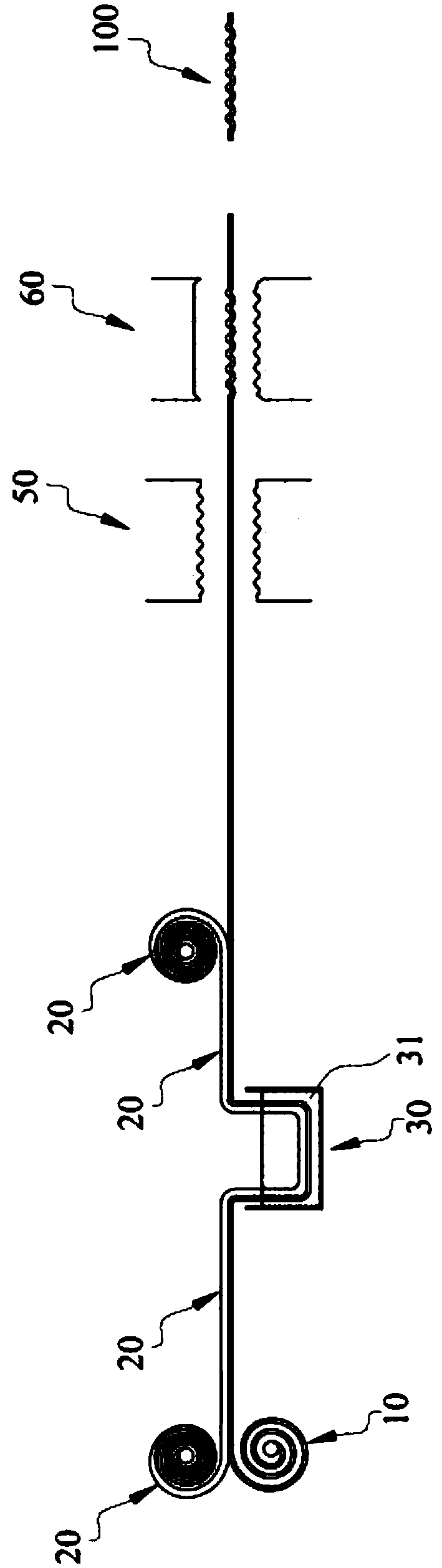

[0032] see figure 1 and figure 2 , which are respectively the flow chart of the manufacturing method and the schematic diagram of the manufacturing process in the first embodiment of the present invention, which disclose a method of elastic wave manufacturing using auxiliary materials to assist in impregnation. The steps of the manufacturing method include:

[0033] A providing step S1 , providing a base material 10 and at least one auxiliary material 20 .

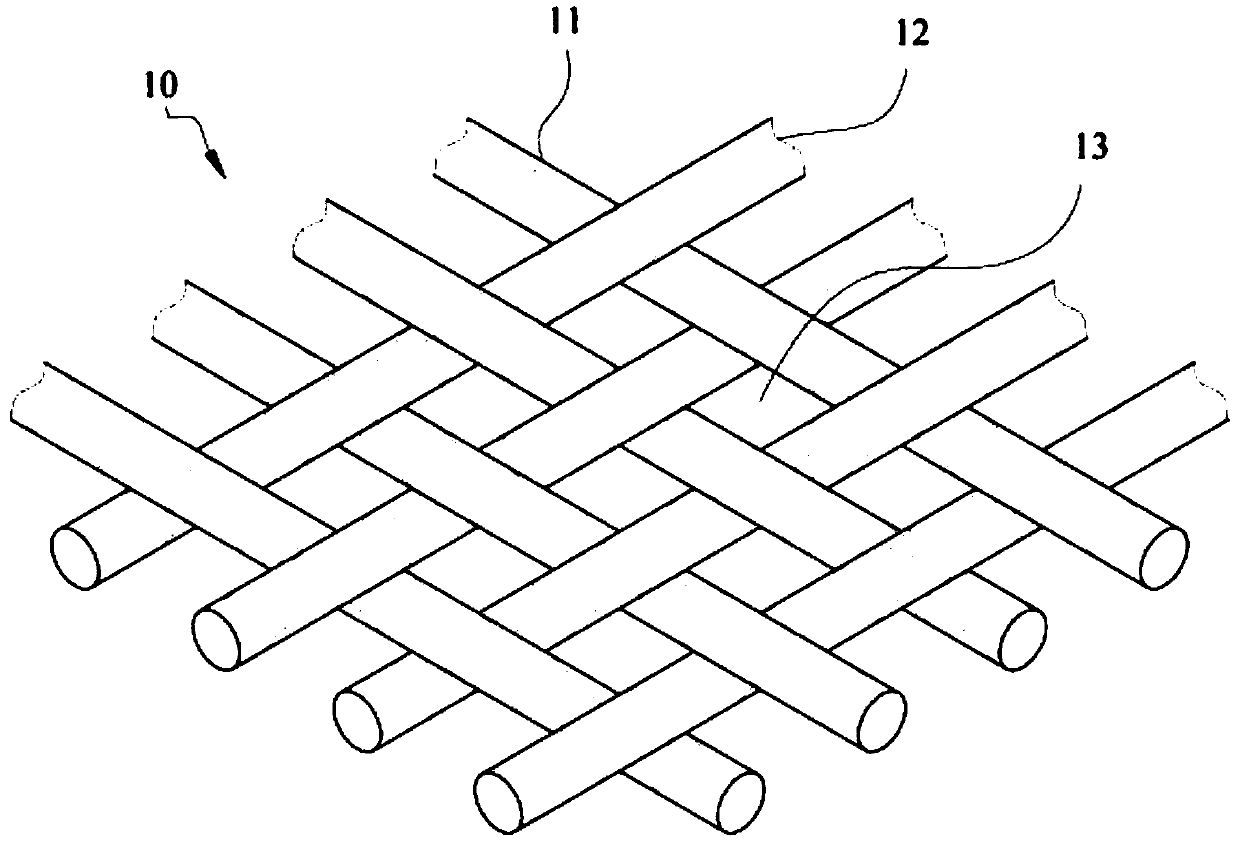

[0034] The base material 10 is the base material of the elastic wave, and is processed in the subsequent steps to form the elastic wave of the horn. Please also see image 3 , which is a partially enlarged schematic view of the substrate 10 . The base material 10 is woven by interlacing a plurality of warp yarns 11 and a plurality of weft yarns 12, and a plurality of gaps are formed between the warp yarns 11 and the weft yarns 12, which are called meshes herein. 13. Warp yarn 11 and weft yarn 12 are selected from pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com