Perovskite solar cell module and packaging method thereof

A technology of solar cells and encapsulation methods, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of thicker and wider, and achieve the effects of enhanced encapsulation, good water blocking effect, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

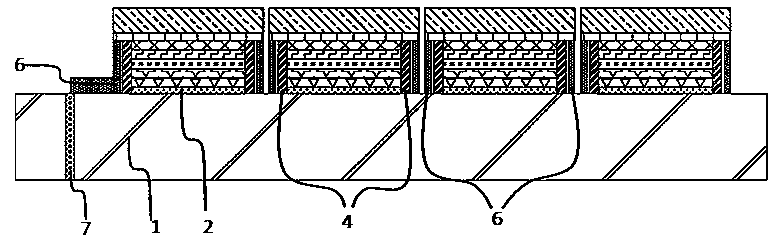

[0066] Such as Figure 1~3 As shown, this embodiment relates to a parallel perovskite solar cell module. The specific implementation steps include:

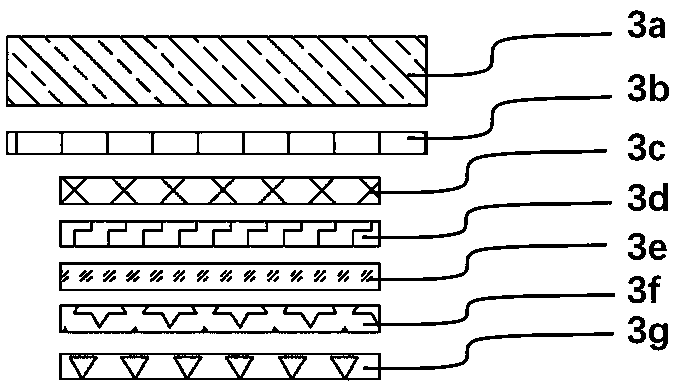

[0067] The perovskite solar cell modules arranged in 2 rows and 4 columns are laid on the tempered glass (bottom substrate 1). A transparent substrate 3a with a transparent conductive layer 3b formed on the lower surface is provided on the perovskite solar cell module. A single perovskite solar cell module includes from top to bottom: a hole blocking layer 3c, an electron transport layer 3d, a perovskite light absorbing layer 3e, a hole transport layer 3f, and a counter electrode layer 3g; wherein, the transparent conductive layer 3b is provided with There is a total electrode 5, which is used as the positive and negative terminals of a single perovskite battery module. A filling layer 2 is laid between a single perovskite solar cell module and the bottom substrate 1 , and encapsulation glue 4 is laid around the single perovsk...

Embodiment 2

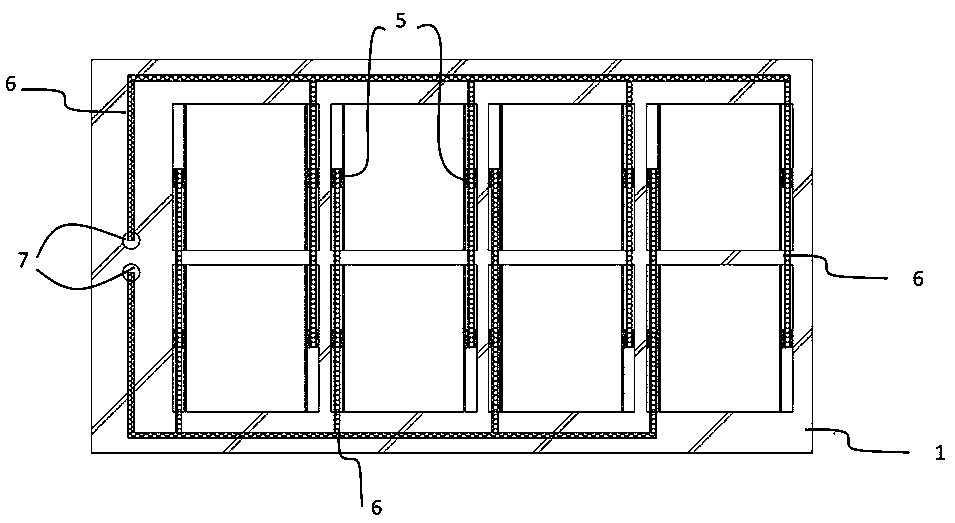

[0071] Such as Figure 5~8 As shown, this embodiment relates to a tandem perovskite solar cell module. The specific implementation steps include:

[0072] When the first row of perovskite solar cell modules are placed, the direction of positive and negative poles is the left side is the negative pole, and the right side is the positive pole; when the second row of perovskite solar cell modules is placed, the direction of the positive and negative poles is the left side is the positive pole , the right side is negative.

[0073] Use conductive copper tape (connecting wire 6) to connect the positive and negative electrodes of the perovskite solar power module laid above, and follow the Figure 7 The perovskite solar cell arrays are connected in series in the same way; after the series connection, the positive and negative electrodes are collected at one end of the tempered glass respectively, and the positive and negative electrodes are respectively passed through the through ...

Embodiment 3

[0076] MAPbI 3 Packaging of perovskite solar cell modules, wherein the perovskite solar cell module contains multiple unit cells, and each unit cell includes an FTO layer (transparent conductive layer 3b), hole blocking layer 3c, electron transport layer 3d, MAPbI 3 Perovskite layer (perovskite light-absorbing layer 3e), hole transport layer 3f, carbon counter electrode layer (counter electrode layer 3g), wherein, MAPbI 3 The perovskite layer is arranged between the electron transport layer and the carbon counter electrode layer; the FTO layers of adjacent unit cells are separated by etching lines, and the counter electrode layer is connected to the FTO layers of adjacent unit cells across the etching lines to achieve 8 The cells are connected in series.

[0077] The perovskite solar cell modules arranged in 2 rows and 2 columns are laid on the tempered glass (bottom substrate 1). A single perovskite solar cell module contains 8 unit cells connected in series, and the positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com