Flow shop production scheduling method for distributed precast concrete components

A technology for prefabricated components and production scheduling, applied in forecasting, manufacturing computing systems, complex mathematical operations, etc., can solve problems such as prefabricated component characteristic analysis, production efficiency decline, and corporate revenue decline, so as to improve algorithm efficiency and improve solution quality , the effect of improving the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

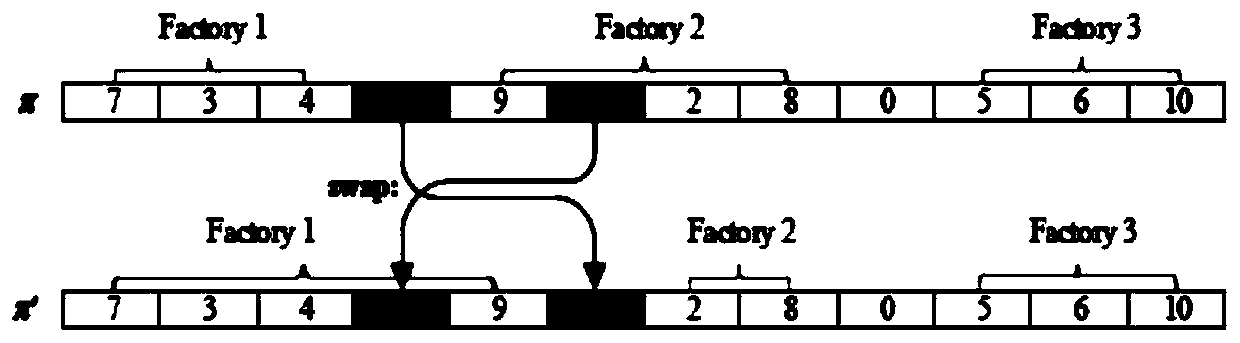

[0064] The present invention provides a production scheduling method for a distributed concrete prefabricated component flow shop, comprising the following steps:

[0065] S1. Collect relevant production data and establish relevant mathematical models;

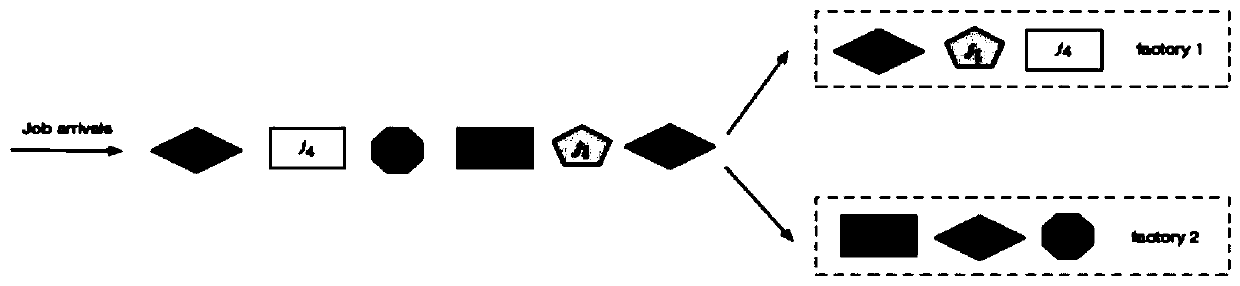

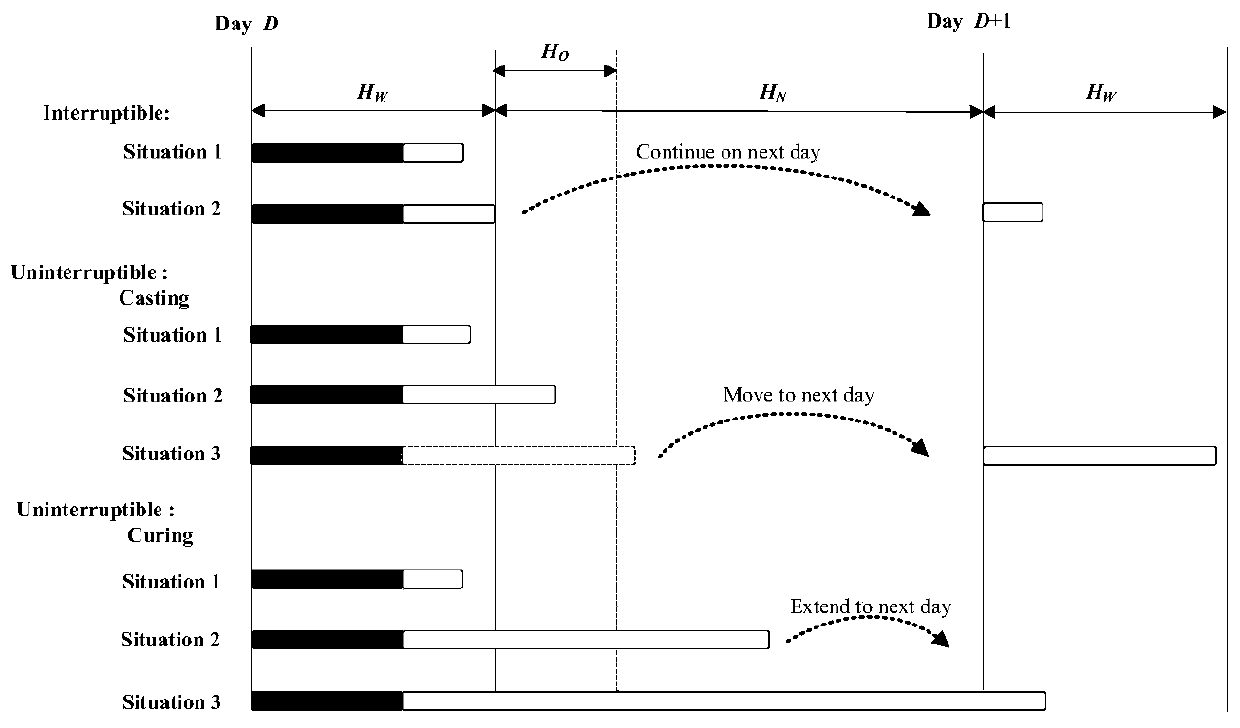

[0066] Relevant production data collection: the number of workpieces, the number of factories, the number of processes, the processing time of workpieces in each process, the operation content and characteristics of each process, the time of factory commute and overtime; to minimize the inventory and delay of distributed factories Penalty cost is used as the target constraint; the distributed production mentioned means that the number of processes is 6, and the number of factories is 2, 3 and 5 respectively.

[0067] The production of prefabricated components is mainly composed of six major processes:

[0068] (1) Mold assembly;

[0069] (2) Place steel bars and embedded parts;

[0070] (3) Concrete pouring;

[0071] (4) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com