Color film substrate, preparation method thereof and display panel

A technology of color filter substrate and base substrate, which is applied to identification devices, instruments, diodes, etc., can solve problems such as the limitation of nozzle accuracy, the inability of quantum dot color filter substrates to meet high-resolution display requirements, and the inability to achieve display requirements, etc. To achieve the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

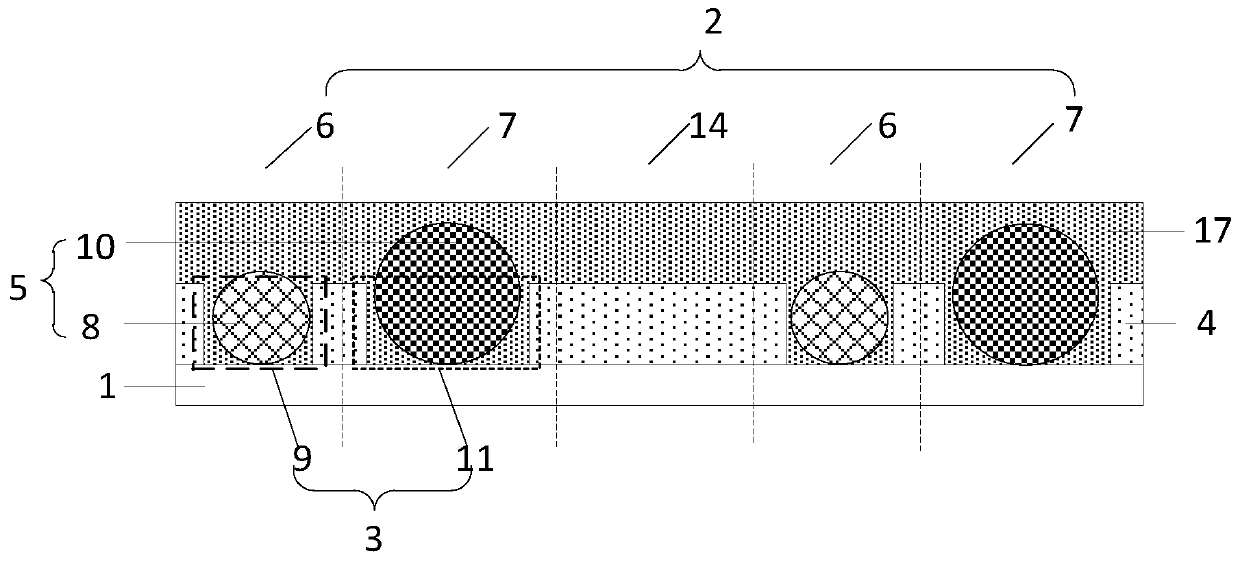

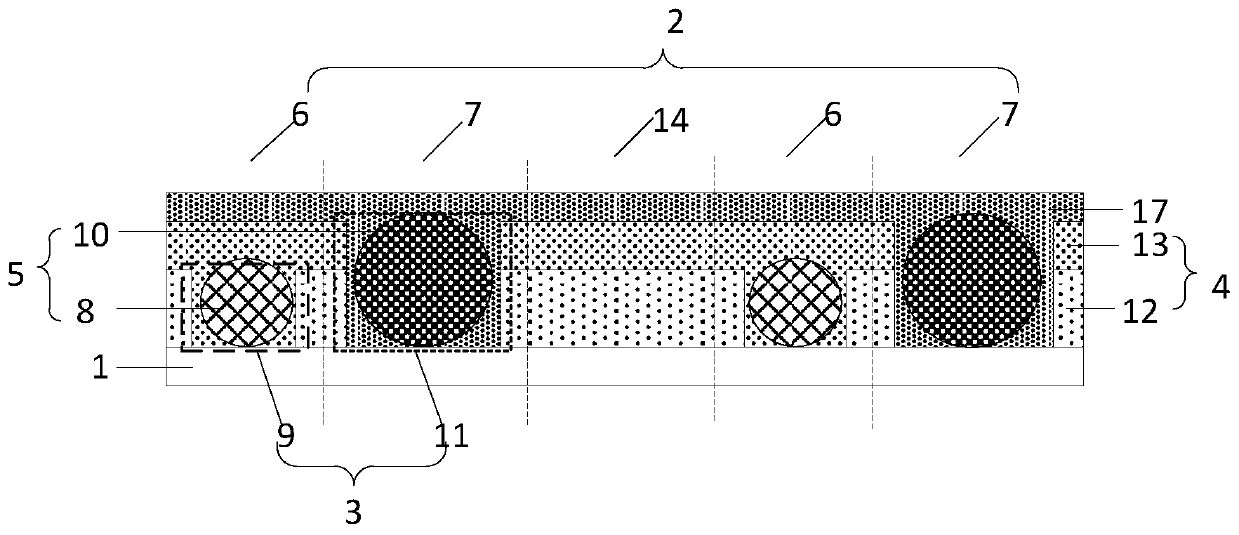

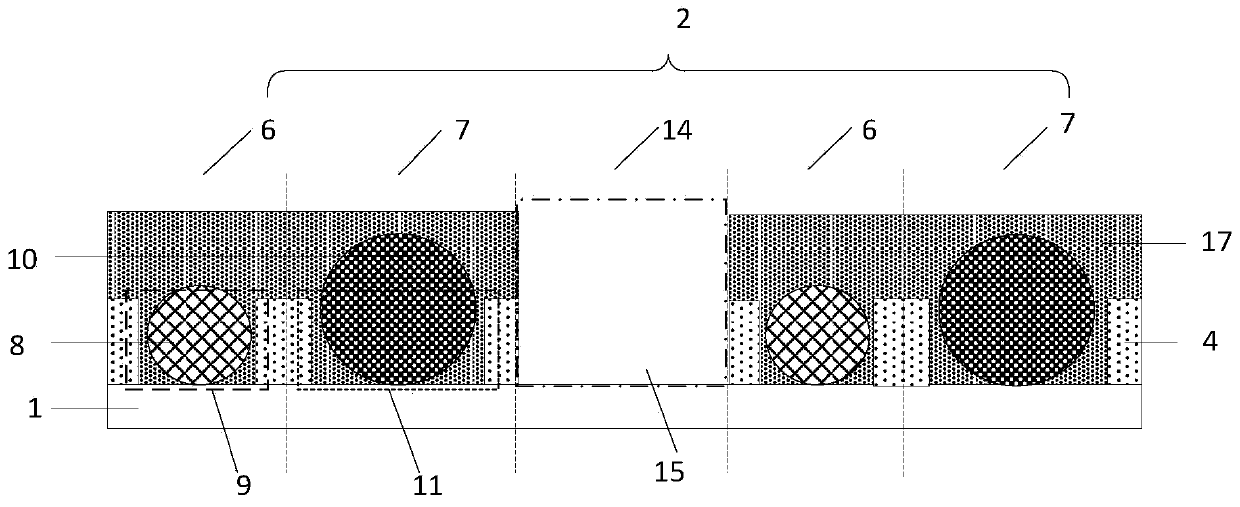

[0061] The embodiment of the application provides a color film substrate, such as figure 1 , figure 2 As shown, the color filter substrate includes: a base substrate 1 and sub-pixel regions 2 arranged in an array on the base substrate 1;

[0062] At least part of the sub-pixel area 2 includes: a light-transmitting layer 4 having a groove 3, and quantum dot microspheres 5 located in the groove 3 and corresponding to the color of light emitted from the sub-pixel area 2; the groove The width of 3 is greater than the diameter of the quantum dot microsphere 5 in the groove 3.

[0063] The color film substrate provided by the embodiment of the present application uses quantum dot microspheres as the color film layer, and the quantum dot microspheres are arranged in the groove of the light-transmitting layer, so that the size of the groove and the corresponding quantum dot microsphere can be adjusted. The diameter of the display product can change the pixel density of the display product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com