Flame-retardant and efficient air filter paper

An air filter paper, high-efficiency technology, applied in the direction of filter paper, filtration separation, membrane filter, etc., can solve the problems of drop, flame retardant blocking performance, easy moisture absorption of flame retardant paper, etc., to achieve excellent filtration performance, flame retardant performance Good, not easy to absorb moisture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

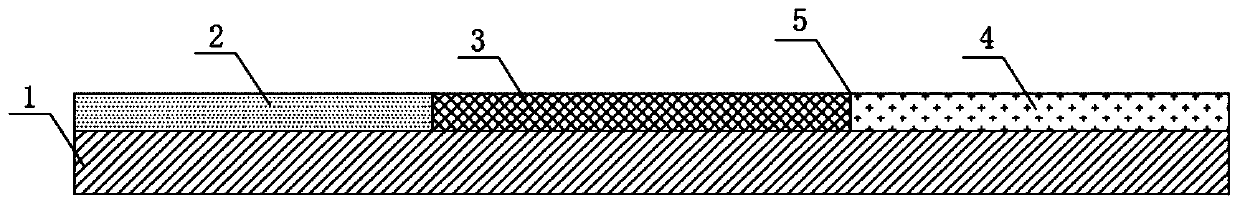

[0034] see Figure 1-2 , The present invention provides a technical solution: a flame-retardant high-efficiency air filter paper, comprising: a base paper sheet 1 and a flame-retardant emulsion 5 .

[0035] Wherein, the flame retardant emulsion 5 includes phenolic resin glue 2 , hydrosol film forming 3 and flame retardant 4 .

[0036] Further, the phenolic resin glue 2 improves the dust holding capacity compared with normal hydrosol film formation.

[0037] Further, the hydrosol film forming 3 provides the required strength for paper forming and certain water resistance.

[0038] Further, flame retardant 4 provides paper flame retardancy.

[0039] Wherein, the flame retardant emulsion 5 is coated on the surface of the base paper sheet 1 .

[0040] Wherein, the phenolic resin glue 2 forms a three-dimensional structure on the surface of the base paper sheet 1 .

[0041] Further, the retention of dust holding capacity is greatly improved.

Embodiment 2

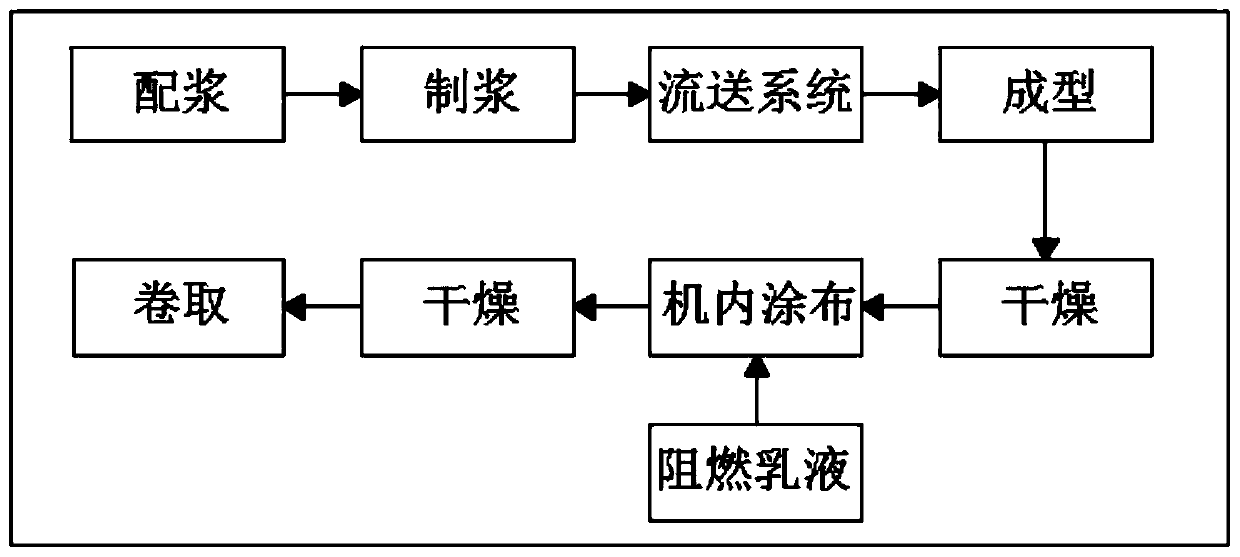

[0043] see figure 2 , the present invention provides a technical solution: a method for preparing flame-retardant and efficient air filter paper, comprising the following steps:

[0044] S1. Pulp preparation: choose hardwood pulp 10% + softwood pulp 65% + polyester fiber 20% + glass fiber 5% raw materials, the addition of polyester fiber and glass fiber can greatly improve performance and service life;

[0045] S2. Pulping: During the pulping process, the wood pulp raw material is crushed by a pulper. The crushing time is 30 minutes, and the concentration is controlled at 7.2%. Then the polyester fiber raw material and the glass fiber raw material are dispersed in the hydraulic pulper. Time 2min;

[0046] S3. Flow delivery system: the wood pulp passes through the deflaker, and the stepped tooth disc deflaker is selected. Without feeding the knife, the polyester fiber and glass fiber also pass through the deflaker to make them more fully dispersed;

[0047] S4. Forming: Send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com