Process for extracting osmanthus fragrans oil by using supercritical carbon dioxide fluid and application of osmanthus fragrans oil

A carbon dioxide and extraction process technology, applied in the preparation of sweet-scented osmanthus oil, application in lip balm and hand cream, and the extraction technology field of supercritical carbon dioxide fluid extraction of sweet-scented sweet-scented osmanthus oil, which can solve the volatile and natural aroma loss of heat-sensitive components of sweet-scented osmanthus essential oil , low extraction rate of essential oils, etc., to achieve the effect of increasing commercial added value, ensuring full utilization, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

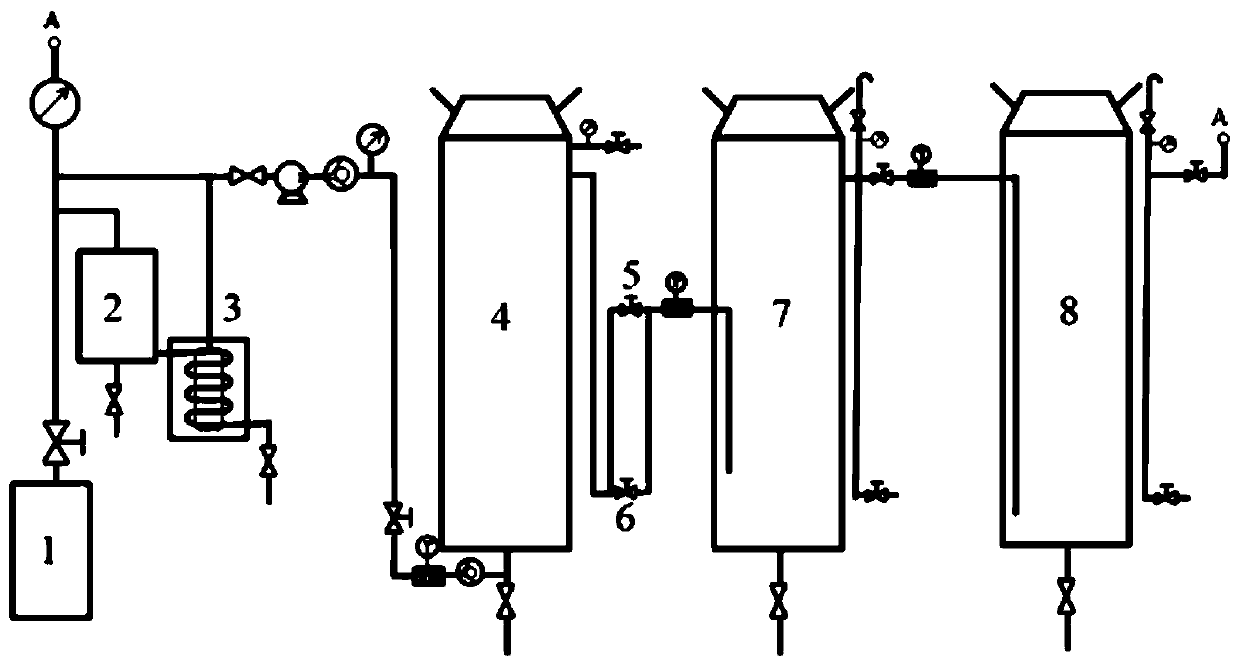

[0042] 1, a kind of extraction process of supercritical carbon dioxide fluid extraction sweet-scented osmanthus oil:

[0043] 1) 800g of fresh sweet-scented osmanthus is freeze-dried in a freeze dryer for 24h to obtain dried sweet-scented osmanthus, and the osmanthus osmanthus cell liquid is collected and stored in a refrigerator;

[0044] 2) Pulverize the dried osmanthus fragrans through a 20-mesh sieve to obtain dry osmanthus fragrans with uniform particles, and use a dry and clean ziplock bag for sealing and storage;

[0045] 3) Different from the traditional supercritical fluid extraction method, 100g of dried osmanthus flower in step 2) needs to be transferred to a 1000ml clean beaker, poured into 150ml of grapeseed oil, and stirred evenly up and down; the beaker is placed in a sonicator for 2-3h. , 10-15 times, 10 minutes each time.

[0046] 4) The sweet-scented osmanthus of step 3) is loaded into the extraction kettle for extraction; the optimized process conditions ar...

Embodiment 2

[0074] 1, a kind of extraction process of supercritical carbon dioxide fluid extraction sweet-scented osmanthus oil, concrete steps are the same as embodiment 1.

[0075] 2. A formulation and preparation process of sweet-scented osmanthus lip balm:

[0076] Calculated by mass percentage, its raw material composition and content are shown in Table 4.

[0077] Table 4

[0078] raw material name Addition amount (wt%) Osmanthus Oil 9.00 olive oil 57.18 Vitamin E 0.75 Coco fat 9.00 Beeswax 24.07

[0079] The sweet-scented osmanthus oil is obtained in step 5) of the supercritical carbon dioxide fluid extraction process.

[0080] The preparation method of above-mentioned sweet-scented osmanthus lip balm, concrete steps are such as embodiment 1.

[0081] 3. The formula and preparation process of a sweet-scented osmanthus hand cream:

[0082] The raw material formulations are shown in Table 5.

[0083] table 5

[0084]

[0085] ...

Embodiment 3

[0090] 1, a kind of extraction process of supercritical carbon dioxide fluid extraction sweet-scented osmanthus oil, concrete steps are the same as embodiment 1.

[0091] 2. A formulation and preparation process of sweet-scented osmanthus lip balm:

[0092] Calculated by mass percentage, the raw material composition and content are shown in Table 6.

[0093] Table 6

[0094]

[0095]

[0096] The sweet-scented osmanthus oil is obtained in step 5) of the supercritical carbon dioxide fluid extraction process.

[0097] The preparation method of above-mentioned sweet-scented osmanthus lip balm, concrete steps are such as embodiment 1.

[0098] 3. The formula and preparation process of a sweet-scented osmanthus hand cream:

[0099] The raw material formulations are shown in Table 7.

[0100] Table 7

[0101]

[0102]

[0103] Described osmanthus oil is supercritical carbon dioxide fluid extraction process step 5) gained;

[0104] The Osmanthus fragrans cell liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com