Reclaimed rubber particle permeable asphalt concrete and preparation method thereof

A technology of permeable asphalt and reclaimed rubber, applied in the field of road materials, can solve the problems of low strength of permeable pavement, poor anti-frost heave ability, insufficient durability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

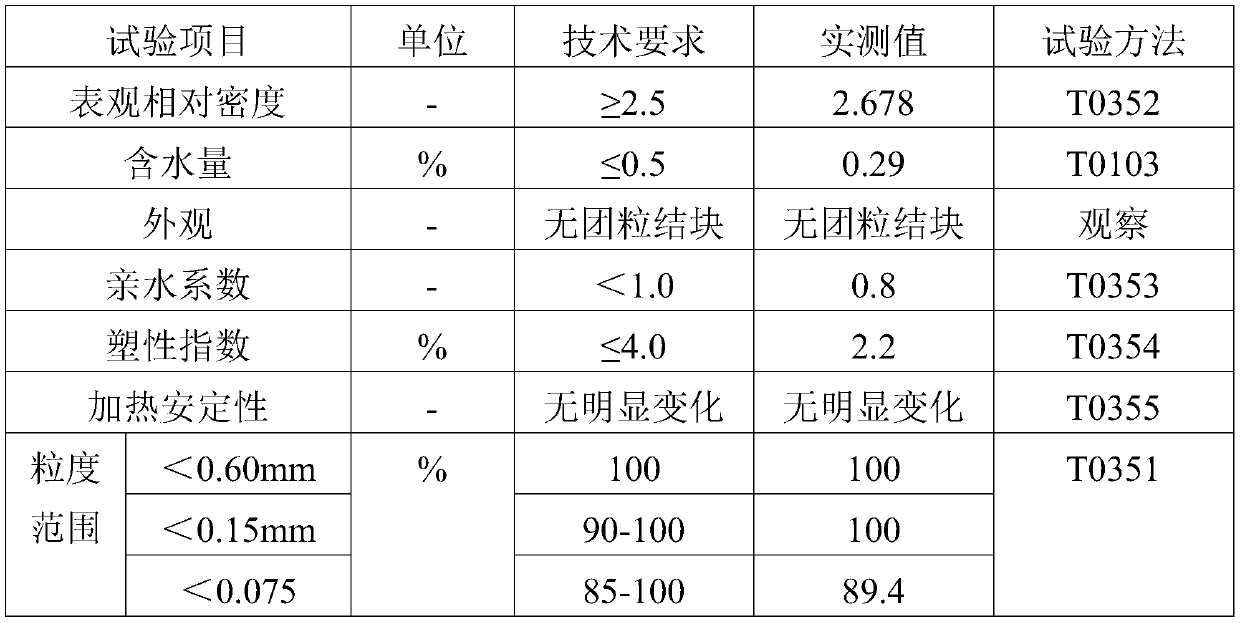

[0035] The invention provides a method for preparing permeable asphalt concrete with recycled rubber particles, comprising the following steps:

[0036] S1, heat the base asphalt to a certain temperature, add the extension agent while stirring, then add SBS and composite stabilizer, keep the temperature constant and continue stirring to obtain the modified asphalt mixture.

[0037] In a specific embodiment of the present invention, the extension agent in step S1 is one or more of rubber oil, furfural oil, waste engine oil, biomass pitch and heavy mineral oil;

[0038] Composite stabilizer comprises the component of following parts by weight: sulfur powder 40-90 parts (such as 40 parts, 45 parts, 50 parts, 55 parts, 60 parts, 65 parts, 70 parts, 75 parts, 80 parts, 85 parts, 90 parts parts), organic sulfur 10-40 parts (such as 10 parts, 15 parts, 20 parts, 25 parts, 30 parts, 35 parts, 40 parts), polyvinyl alcohol 10-20 parts (such as 10 parts, 11 parts, 12 parts , 13 parts, 1...

Embodiment 1

[0067] This embodiment provides a method for preparing permeable asphalt concrete with recycled rubber particles, which includes the following steps:

[0068] S1, add 100 parts by mass of base asphalt into a mixing tank and heat to 185°C, add 2.5 parts by mass of rubber oil while stirring, then add 6 parts by mass of SBS and 0.15 parts by mass of composite stabilizer, and keep the temperature at 150°C constant Continue to stir to obtain the mixture; wherein the composite stabilizer includes the following components by weight: 60 parts of sulfur powder, 25 parts of organic sulfur, 15 parts of polyvinyl alcohol, 15 parts of stearyl benzoyl methane and 5 parts of nano-zinc oxide ;

[0069] S2, placing the mixture obtained in step S1 in a colloid mill for shearing, storing and developing at 150° C. for 7 hours, and finally obtaining SBS modified asphalt;

[0070] S3, adding 10 parts by mass of old tire rubber powder particles to the SBS modified asphalt in step S2, stirring at 19...

Embodiment 2

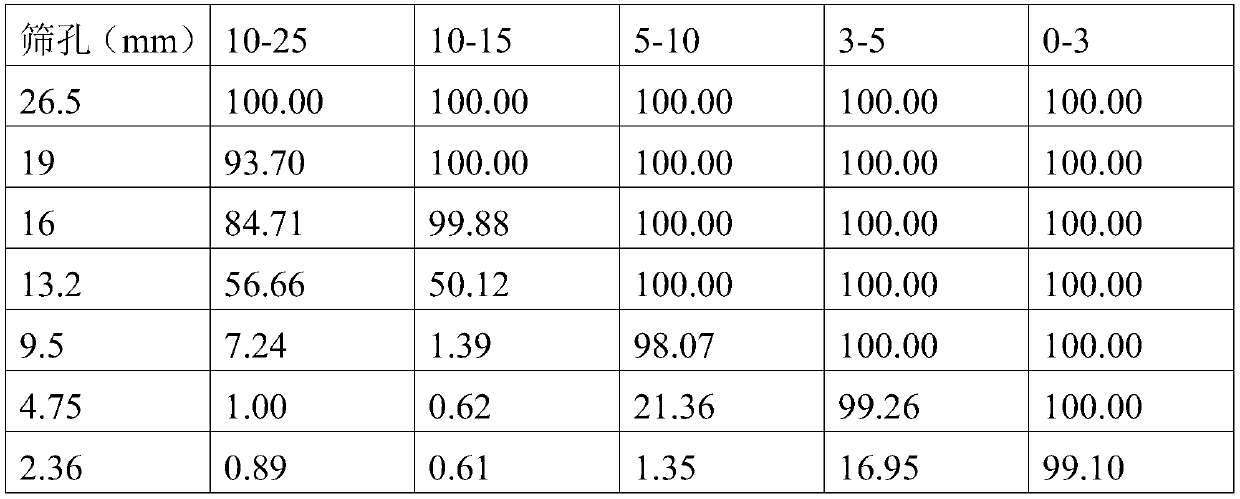

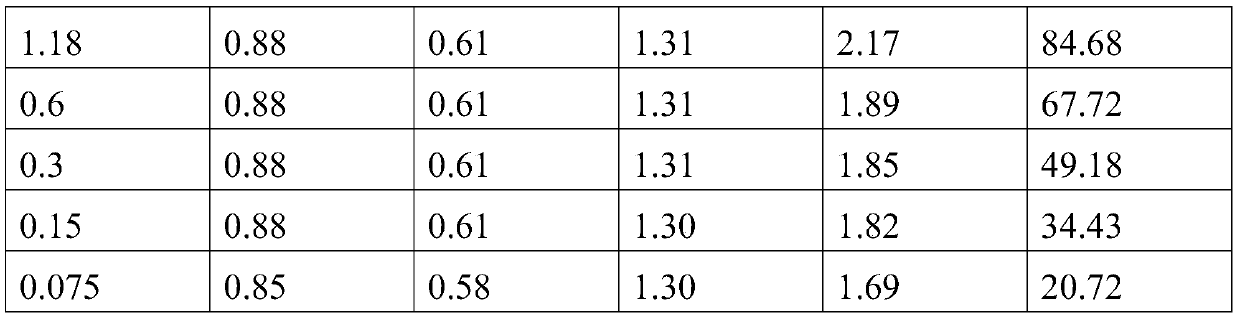

[0083] This embodiment provides a method for preparing permeable asphalt concrete with regenerated rubber particles. The difference between this embodiment and Embodiment 1 is that in step S4, the mass ratio of SBS regenerated rubber particles modified asphalt to different graded batches is changed. That is to change the asphalt ratio of recycled rubber particle permeable asphalt concrete with different gradations. The oil-stone ratio of PAC20 recycled rubber particle permeable asphalt concrete is 4.5%, 5%, 5.5% and 6%. The oil-stone ratio of PAC16 recycled rubber particle permeable asphalt concrete is 4.5%, 5%, 5.5% and 6%, the oil-stone ratio of PAC13 recycled rubber particle permeable asphalt concrete is 5%, 5.5%, 6% and 6.5%, the oil-stone ratio of PAC10 recycled rubber particle permeable asphalt concrete is 5%, 5.5% %, 6% and 6.5%; the mass percentages of each component in batches of different grades are shown in Table 5 below.

[0084] The mass percent of each component ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com