A kind of preparation method and preparation system of lithium-ion battery cathode material precursor

A technology for lithium-ion batteries and positive electrode materials, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., to achieve a wide range of applications, strong operability, and the effect of reducing the content of micropowder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

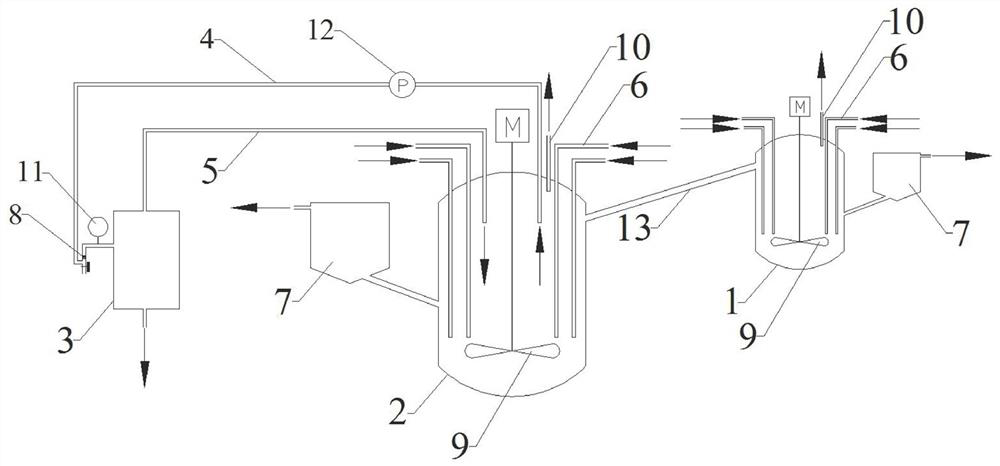

Method used

Image

Examples

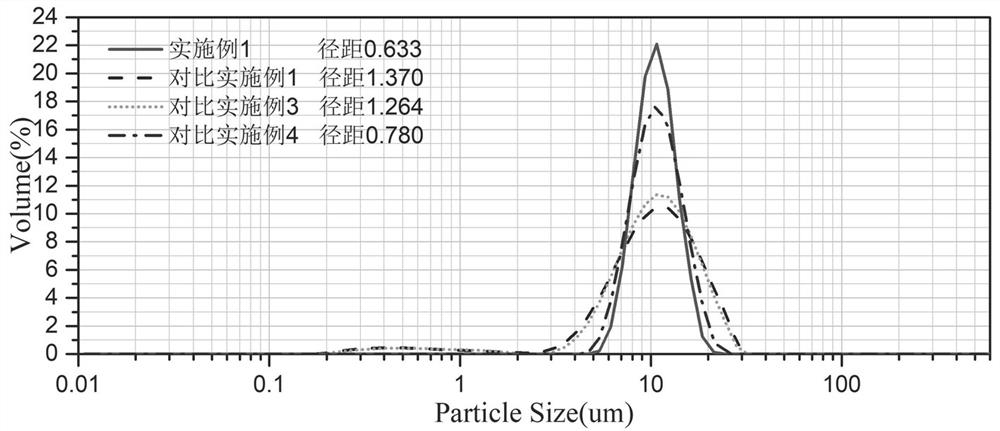

Embodiment 1

[0049] A preparation method of a lithium-ion battery positive electrode material precursor, the method is used to prepare a D50 of 10.5 μm, a slurry diameter of 0.633 precursor products, comprising the following steps:

[0050] (1) Prepare nickel sulfate, cobalt sulfate, and manganese sulfate solutions with a total metal concentration of 2mol / L, the molar ratio of nickel, cobalt, and manganese is 6:2:2, prepare 2mol / L sodium hydroxide solution and 6mol / L ammonia aqueous solution.

[0051] (2) Add the mixed salt solution of nickel, cobalt and manganese into the primary reaction kettle, and at the same time feed the sodium hydroxide solution and ammonia solution, and control the feed flow rate of the mixed salt solution of nickel, cobalt and manganese to 1L / min to maintain the primary reaction The pH value in the kettle is 11.0-11.5, the concentration of ammonium ion is 20g / L, the reaction temperature is 55°C, the stirring speed is 400rpm, and nitrogen protection is introduced i...

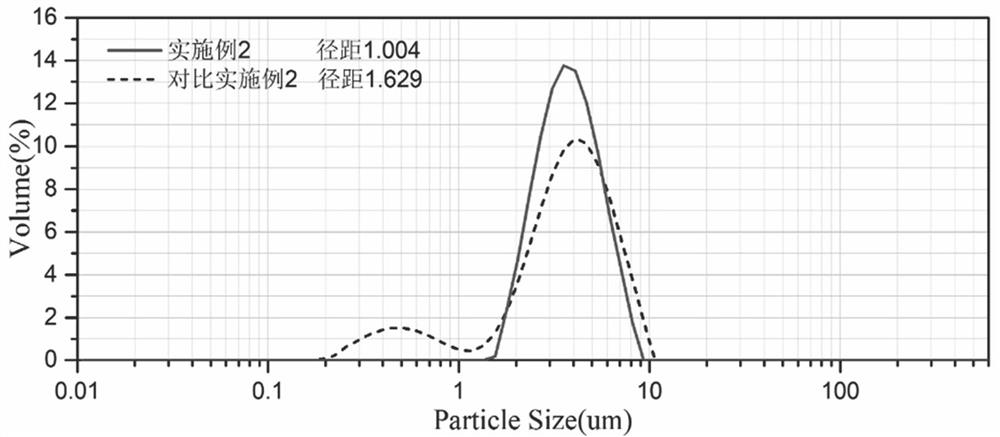

Embodiment 2

[0058] A preparation method of a lithium-ion battery positive electrode material precursor, the method is used to prepare a D50 of 3.7 μm, a slurry diameter of 1.004 of the precursor product, comprising the following steps:

[0059] (1) Prepare a solution of nickel sulfate, cobalt sulfate and manganese sulfate with a total metal concentration of 2mol / L, the molar ratio of nickel, cobalt and manganese is 5:2:3, prepare 2mol / L sodium hydroxide solution and 6mol / L ammonia aqueous solution.

[0060] (2) Add the mixed salt solution of nickel-cobalt-manganese into the primary reactor, and feed the sodium hydroxide solution and ammonia solution at the same time, control the feed flow rate of the mixed salt solution of nickel-cobalt-manganese to 1.2L / min, and keep the reactor The pH value in the reactor is 11.0-11.5, the ammonium ion concentration is 10g / L, the reaction temperature is 60°C, the stirring speed is 500rpm, and nitrogen protection is introduced into the reactor. By adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com