Crystallizer for copper alloy electromagnetic continuous casting

A copper alloy and mold technology, which is applied in the field of molds for electromagnetic continuous casting of copper alloys, can solve the problems of low production efficiency, surface defects, large grain size, etc. Internal quality, overcoming the effect of large grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. What needs to be declared here is that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not conflict with each other.

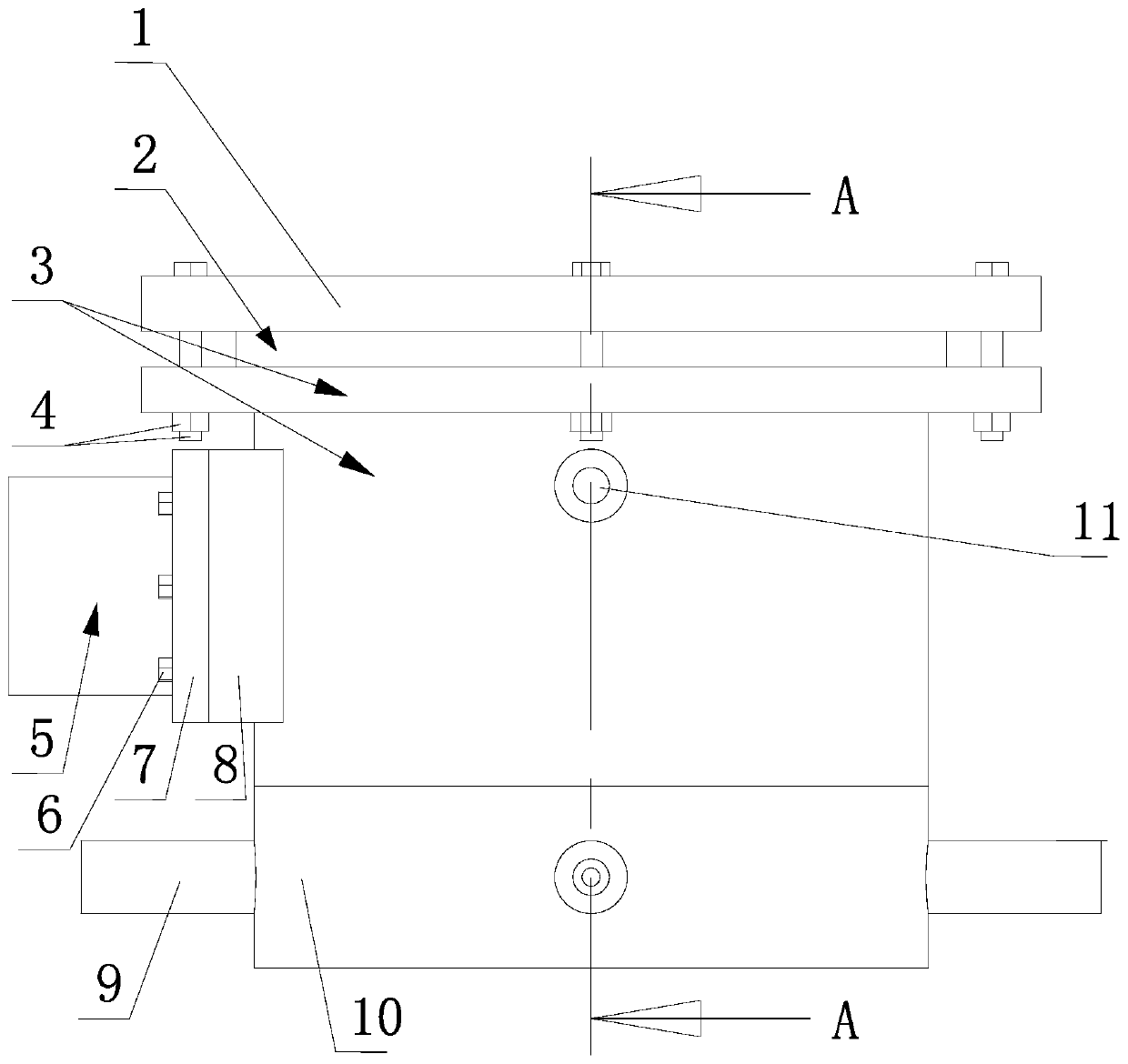

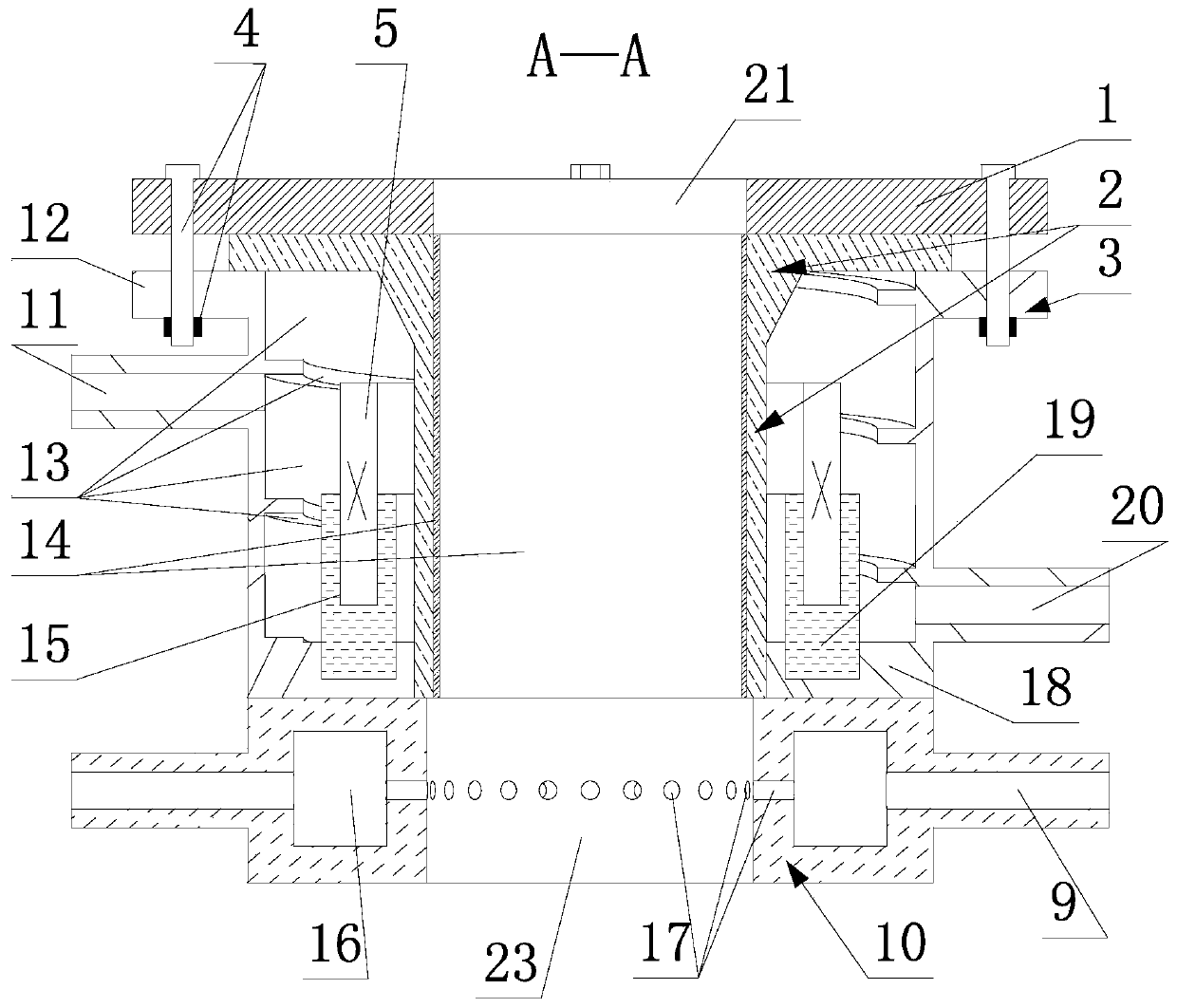

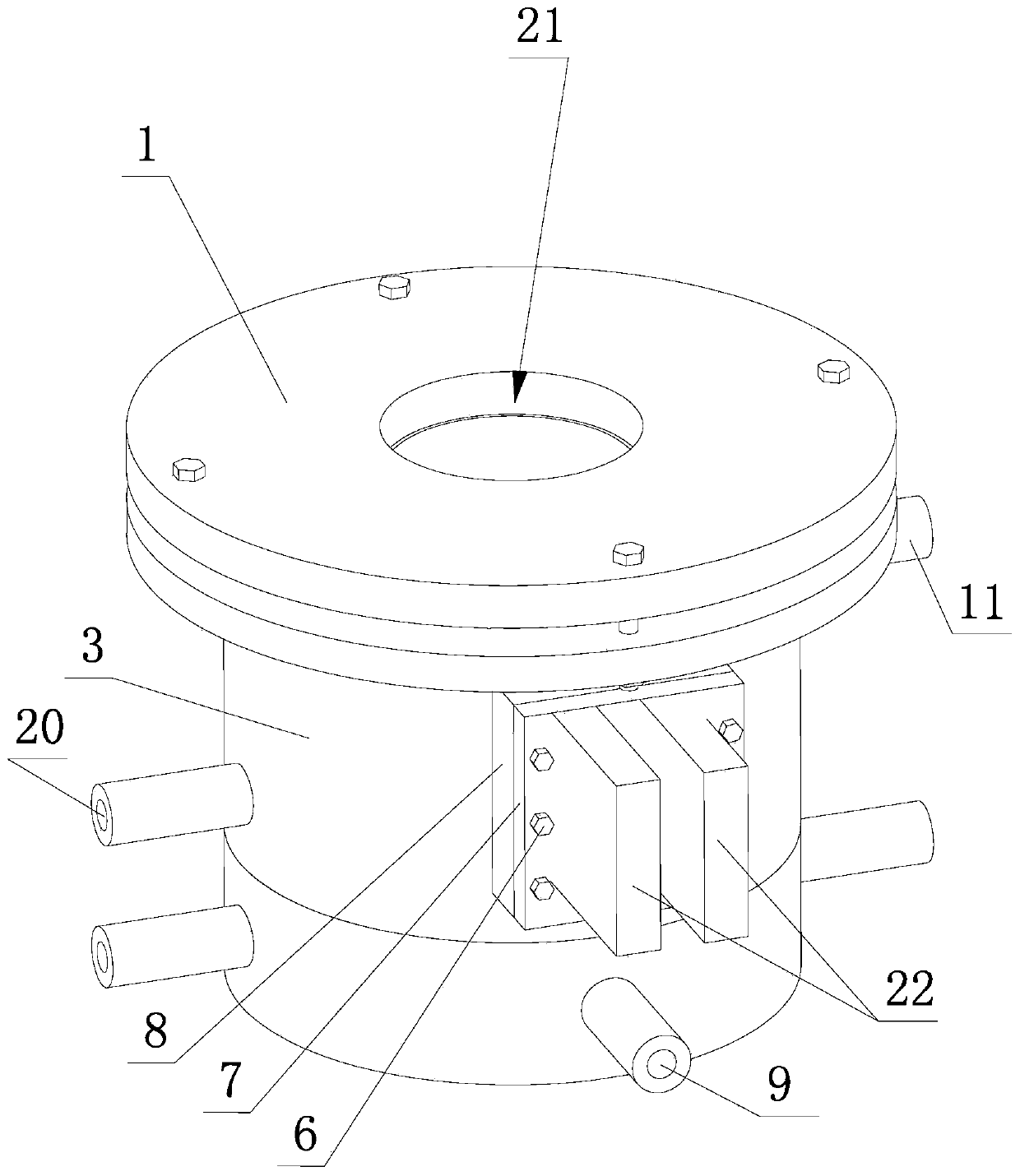

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 shown

[0028]The copper alloy electromagnetic continuous casting crystallizer of the present invention comprises a copper alloy liquid inlet, a copper alloy accommodating cavity, a copper ingot outlet, an upper cover 1, a slotted crystallizer cylinder body 2, a first cooling water jacket 3 and a first cooling water jacket fixed on the first The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com