A kind of stamping die and its stamping forming method

A technology of stamping dies and stamping forming, which is applied in the field of molds to achieve the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

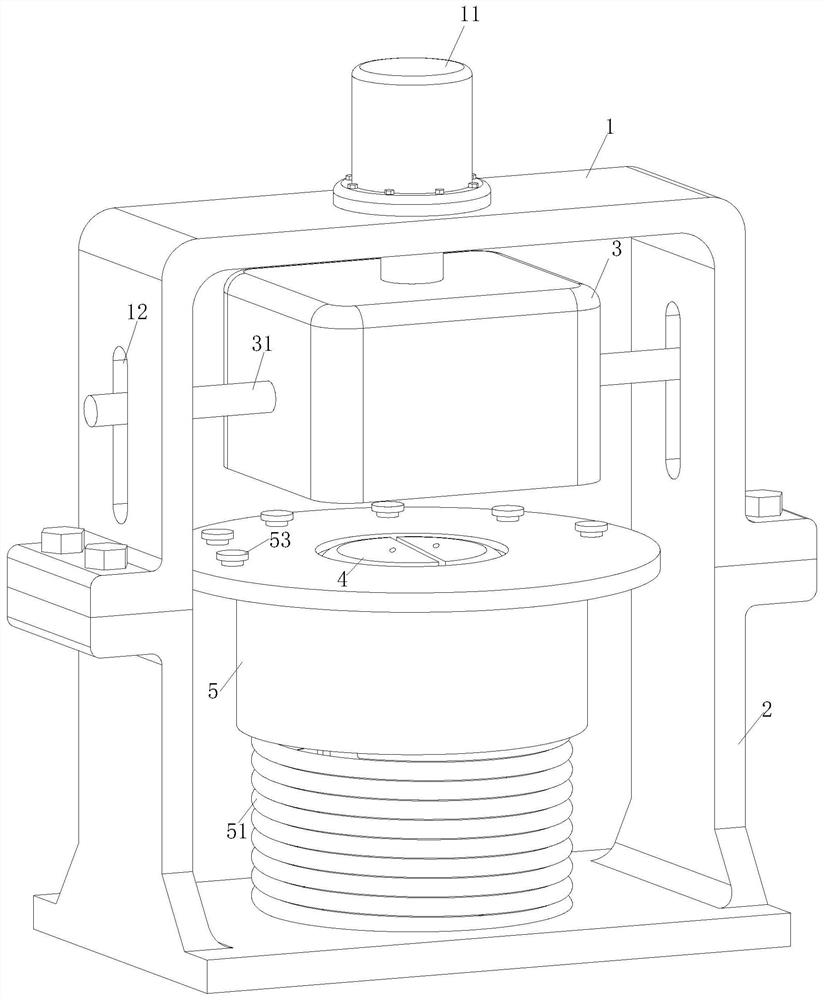

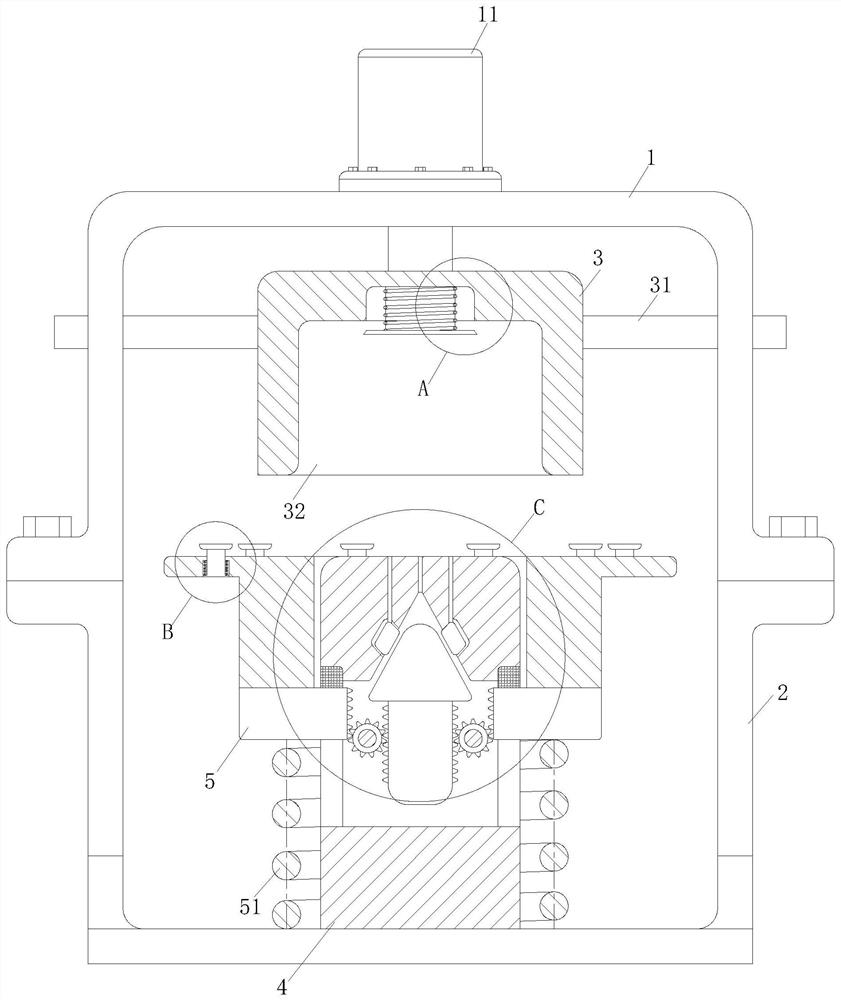

Image

Examples

specific Embodiment approach

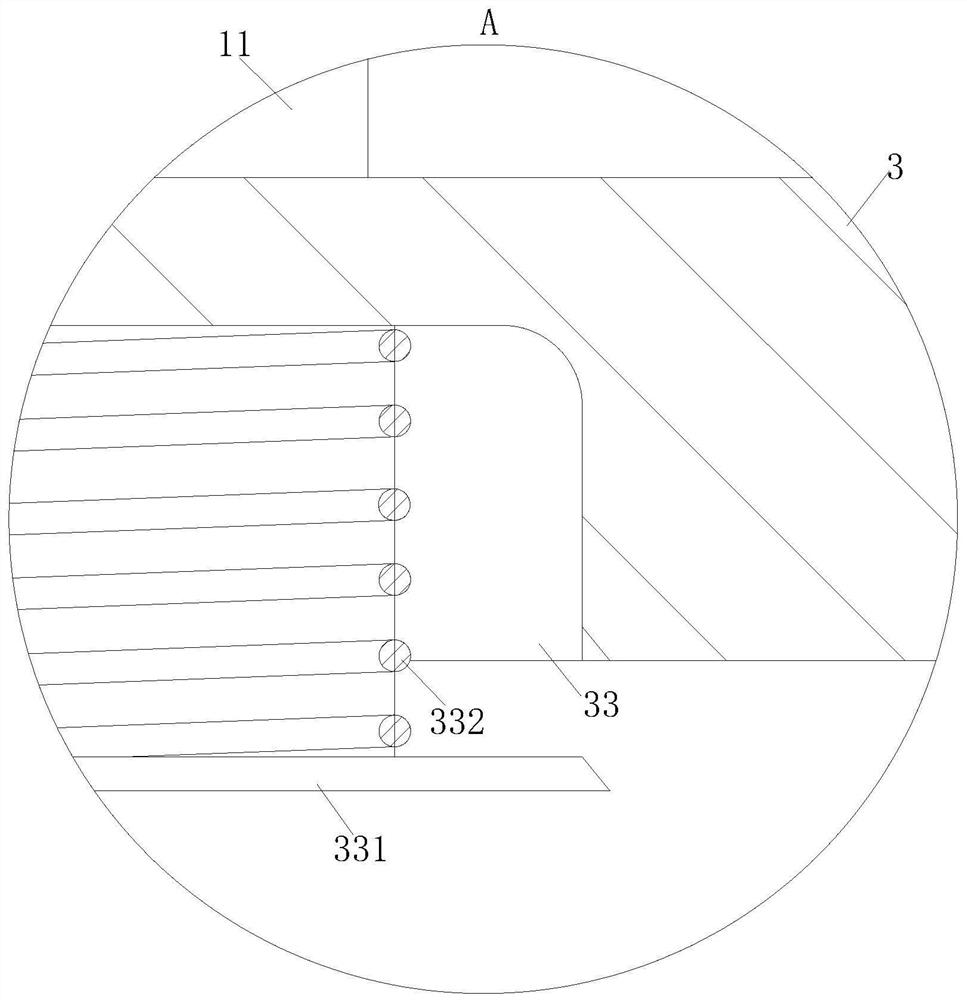

[0028] As a specific embodiment of the present invention, the inner bottom surface of the first groove 32 is provided with a second groove 33, and a push plate 331 is arranged in the second groove 33; the push plate 331 is connected to the second groove by a second spring 332 33 inner bottom surface; through the cooperation between No. 2 spring 332 and push plate 331, prevent the parts after stamping from being embedded in No. 1 groove 32; There will be sliding friction between the No. 1 groove 32, and the parts will also have active friction with the outer wall of the fixed mold 4. If the active friction between the parts and the No. 1 groove 32 is greater than the friction between the parts and the fixed mold 4, the parts will When demolding, the parts will be clamped in the No. 1 groove 32, and when the movable mold 3 is lifted by the cylinder 11, the stamped parts will rise together with the movable mold 3, and then the stamped parts will be removed manually, at this time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com