Automatic machining equipment for water distribution pipe of cooling tower

A technology of processing equipment and water pipes, which is applied in the field of cooling towers, can solve problems such as large gap walls that are not easy to weld and affect product quality, and achieve good winding effects, high work efficiency, and easy winding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

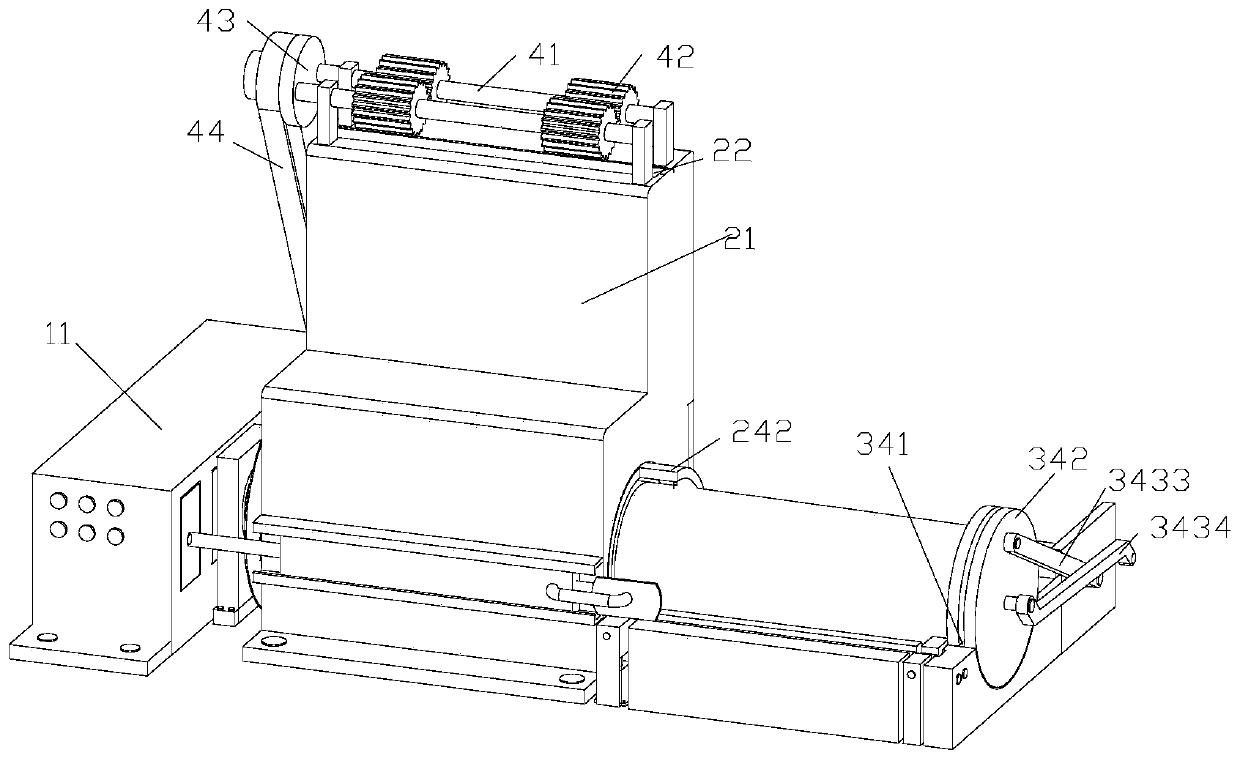

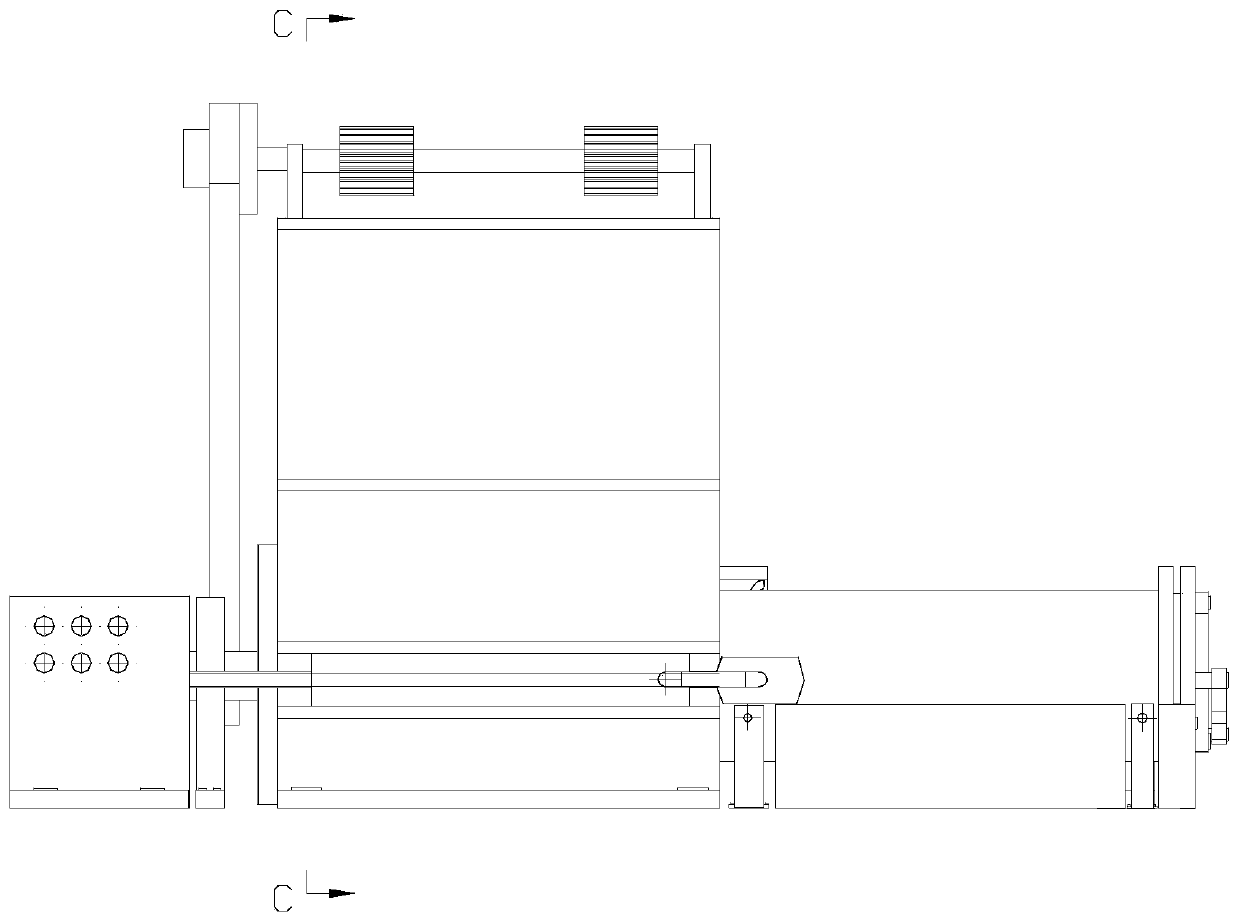

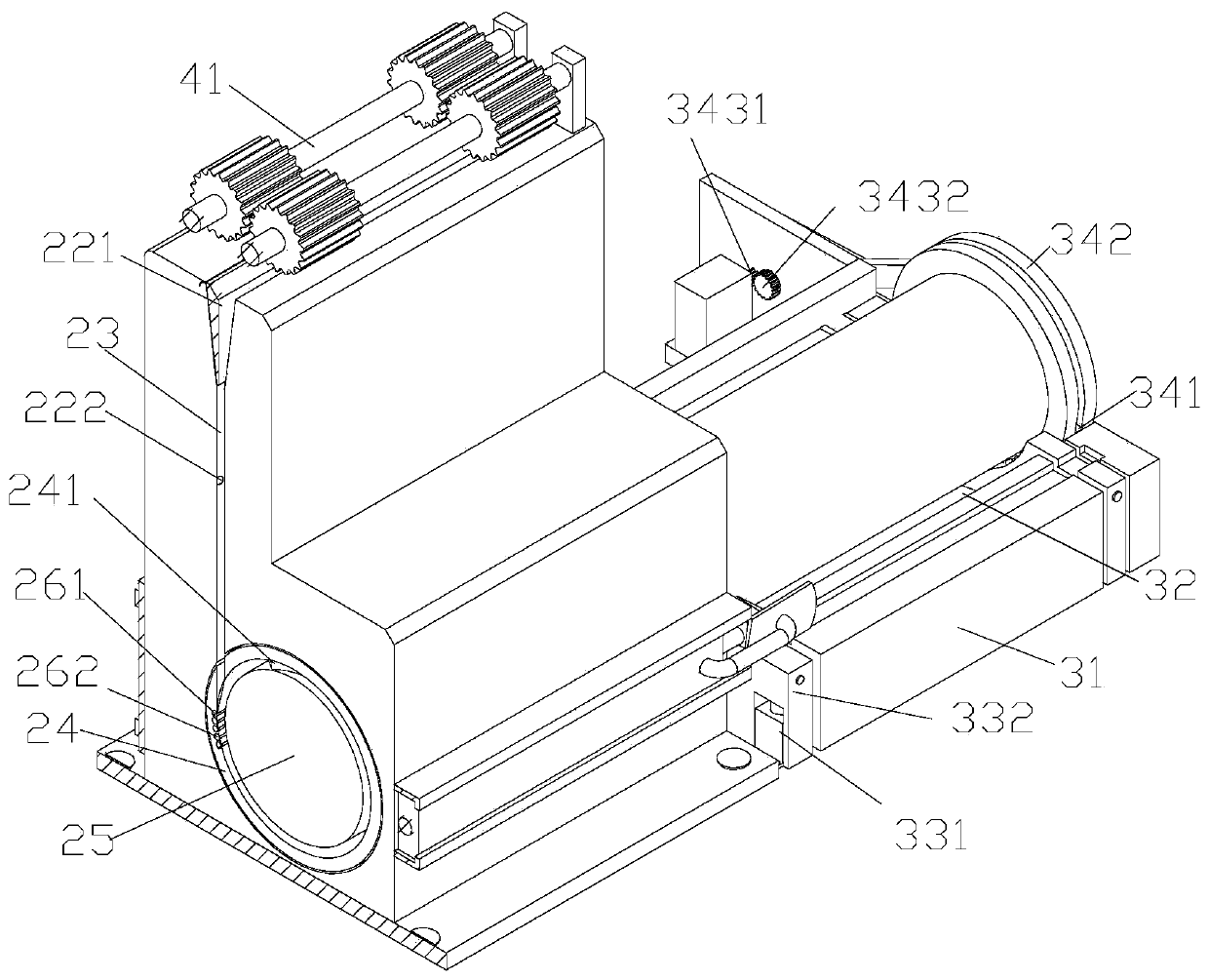

[0024] like Figure 1-9 As shown, an automatic processing equipment for cooling tower cloth water pipes includes a driving device that provides power for coiling steel plates, a coiling device for coiling steel plates into a cylindrical shape, a welding device, and a device for exporting the coiled steel plates Output device, the winding device includes a body 21, a feed port 22 arranged on the body 21, a channel 23 communicated with the feed port 22, an outer cylinder 24 for shaping the outside of the steel plate, and an outer cylinder 24 for shaping the inside of the steel plate. The inner cylinder 25 and the preloading part for guiding the steel plate; the preloading part includes a first pressing roller 261, at least one second pressing roller 262, a first gear 2611 located at one end of the first pressing roller 261 , the second gear 2612 located at the other end of the first pressure roller 261 and the second pressure roller 262, the synchronous parts and the driving par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com