A kind of in-situ growth nickel-based mofs film photocatalyst on the surface of foamed nickel and its preparation method and application

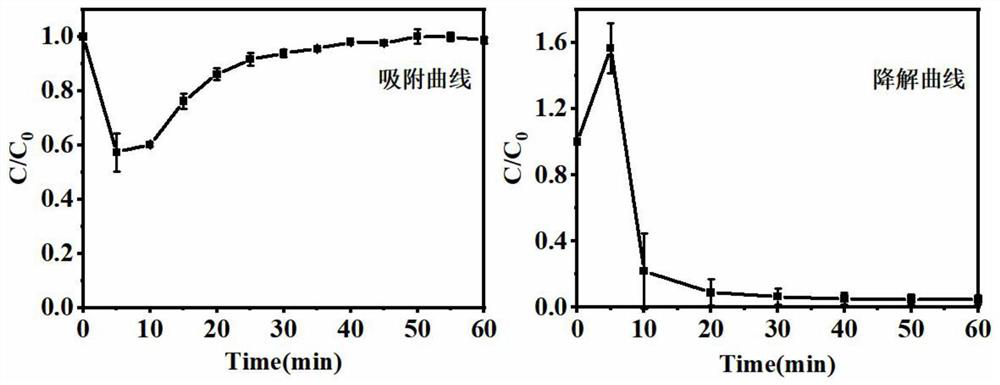

An in-situ growth and photocatalyst technology, applied in the field of photocatalytic materials, can solve the problems of small specific surface area of semiconductor catalysts, high recombination rate of photogenerated carriers, and low degradation efficiency of VOCs, and achieve rapid photogenerated carrier separation ability, The effect of excellent adsorption capacity and good electron conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

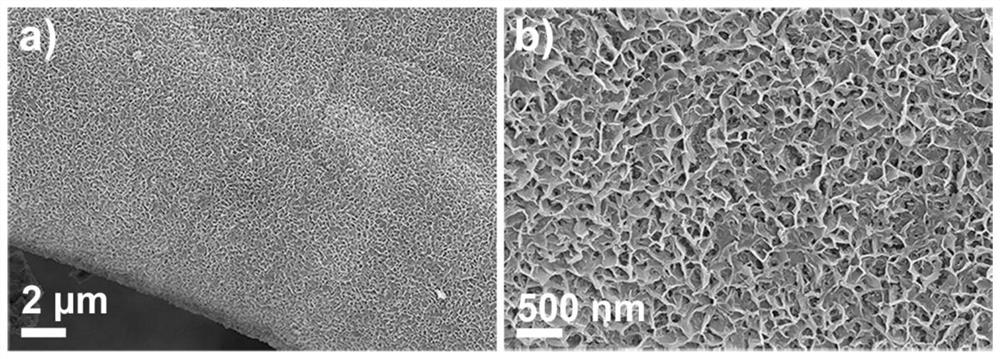

[0030] 1. Use dilute hydrochloric acid (0.5mol / L) and deionized water to soak the ultrasonic size to 1cm 2 The foam nickel, wash away the surface stains, oxide film and organic matter of the foam nickel, so that the foam nickel reveals a fresh surface. Then, put the cleaned foamed nickel into a vacuum drying oven at 60° C. to dry to obtain surface-activated foamed nickel.

[0031] 2. Immerse the surface-activated nickel foam in a polytetrafluoroethylene reaction kettle with a molar ratio of 1:1:100 of 2-methylimidazole, methanol and sodium formate mixture, place it in an oven, set the program, 1°C / Min was raised to 120°C and kept at this temperature for 12 hours. After the reaction was completed, the temperature was lowered to room temperature to obtain an unactivated nickel-based MOFs film grown on the surface of nickel foam;

[0032] 3. After cross-washing the unactivated nickel-based MOFs film grown on the surface of nickel foam with alcohols and deionized water, put it i...

Embodiment 2

[0035] 1. Use dilute hydrochloric acid (6mol / L) and deionized water to soak the ultrasonic size to 1cm 2 The foam nickel, wash away the surface stains, oxide film and organic matter of the foam nickel, so that the foam nickel reveals a fresh surface. Then, put the cleaned foamed nickel into a vacuum oven to dry at 60° C. to obtain surface-activated foamed nickel;

[0036] 2. Immerse the surface-activated nickel foam into 2-methylimidazole, methanol and sodium formate with a molar ratio of 10:1:200, mix them into a reaction kettle with polytetrafluoroethylene, place it in an oven, set the program, 5°C / Min was raised to 100°C and kept at this temperature for 12 hours. After the reaction was completed, the temperature was lowered to room temperature to obtain an unactivated nickel-based MOFs film grown on the surface of nickel foam;

[0037] 3. After cross-washing the unactivated nickel-based MOFs film grown on the surface of nickel foam with alcohols and deionized water, put i...

Embodiment 3

[0039] 1. Use dilute hydrochloric acid (3mol / L) and deionized water to soak the ultrasonic size to 1cm 2 The foam nickel, wash away the surface stains, oxide film and organic matter of the foam nickel, so that the foam nickel reveals a fresh surface. Then, put the cleaned foamed nickel into a vacuum oven to dry at 60° C. to obtain surface-activated foamed nickel;

[0040] 2. Immerse the surface-activated nickel foam into imidazole, DMF and sodium formate with a molar ratio of 5:1:150, mix them into a reaction kettle with polytetrafluoroethylene, place it in an oven, set the program, and raise it to 180 at 10°C / min. ℃, and kept at this temperature for 4h, after the reaction was completed, the temperature was lowered to room temperature, and an unactivated nickel-based MOFs film grown on the surface of nickel foam was obtained;

[0041] 3. After cross-washing the unactivated nickel-based MOFs film grown on the surface of nickel foam with alcohols and deionized water, put it in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com