High-efficiency protective mask based on full-fiber electret generator and preparation method thereof

An electret and generator technology, which is used in life-saving equipment, respiratory protection devices, respiratory protection containers, etc., can solve the problems affecting the filtration stability and service life of mask materials, poor wear resistance and poor flexibility of friction materials, etc. , to achieve good flexibility, ensure stability, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

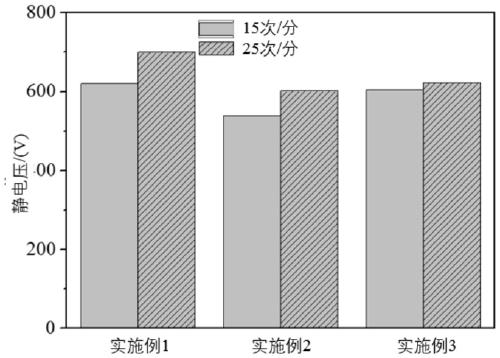

Embodiment 1

[0042] A high-efficiency protective mask based on an all-fiber electret generator of the present embodiment and a preparation method thereof, the specific steps are:

[0043](1) Accurately weigh 16.2 g of N-N dimethylformamide and 10.8 g of acetone in a 50 mL beaker with an electronic balance, then weigh 0.05 g of nano-silicon dioxide (purity 99.5%, average particle size 20 nm) in In the above mixed solvent, then use an electronic balance to accurately weigh 3.0 g of polyvinylidene fluoride and place it in the above beaker, add a stirrer, and stir for 8 h with a magnetic stirrer at 60 °C, with a stirring power of 200 W, and configure it to be uniform and stable. spinning solution.

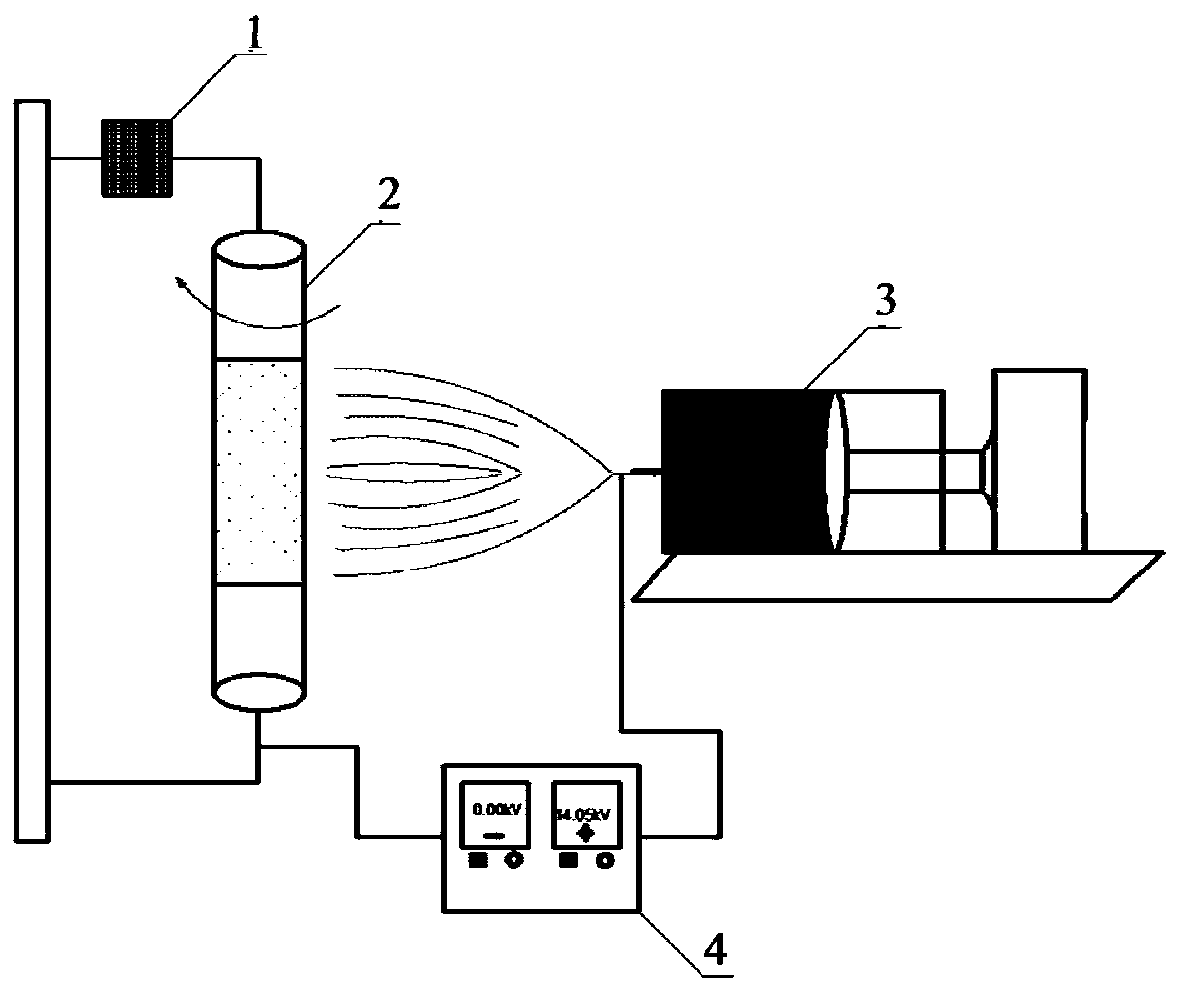

[0044] (2) Draw polyvinylidene fluoride spinning solution with a syringe, use figure 1 The electrospinning equipment shown (composed of voltage protection system 1, drum receiving control system 2, spinning solution injection system 3 and high-voltage electrostatic system 4, the same below) perfor...

Embodiment 2

[0051] A high-efficiency protective mask based on an all-fiber electret generator of the present embodiment and a preparation method thereof, the specific steps are:

[0052] (1) Accurately weigh 16.2 g of N-N dimethylformamide and 10.8 g of acetone in a 50 mL beaker with an electronic balance, then weigh 0.03 g of nano-silicon nitride (purity 99.5%, average particle size 30 nm) in In the above mixed solvent, then use an electronic balance to accurately weigh 3.6 g of polyvinylidene fluoride and place it in the above beaker, add a stirrer, and stir for 8 h at 80°C with a magnetic stirrer, with a stirring power of 300 W, and configure it to be uniform and stable. spinning solution.

[0053] (2) Draw polyvinylidene fluoride spinning solution with a syringe, use figure 1 The electrospinning equipment shown is used for electrospinning, and the non-woven fabric is used as the receiving substrate, and the electrospinning parameters are adjusted: the electrostatic high voltage is 20...

Embodiment 3

[0060] A high-efficiency protective mask based on an all-fiber electret generator of the present embodiment and a preparation method thereof, the specific steps are:

[0061] (1) Accurately weigh 30 g of dichloromethane with an electronic balance and place it in a 50 mL beaker, then weigh 0.03 g of nano-zinc oxide (average particle size 30 nm) and place it in the above solvent, and then accurately weigh 2.4 g of dichloromethane with an electronic balance. g polycarbonate was placed in the above-mentioned beaker, and ultrasonically vibrated at 60°C for 6 h with an ultrasonic power of 200 W to form a uniform and stable spinning solution.

[0062] (2) Draw the polycarbonate spinning solution with a syringe, use figure 1 The electrospinning equipment shown is used for electrospinning, and the non-woven fabric is used as the receiving substrate, and the electrospinning parameters are adjusted: the electrostatic high voltage is 25 KV, the receiving distance is 12 cm, the injection s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com