Nourishing and repairing lyophilized powder and preparation method thereof

A technology of freeze-dried powder and solvent, applied in the field of cosmetics, can solve the problems of not being able to retain active ingredients, achieve excellent anti-inflammatory properties, improve skin elasticity, and smooth fine wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

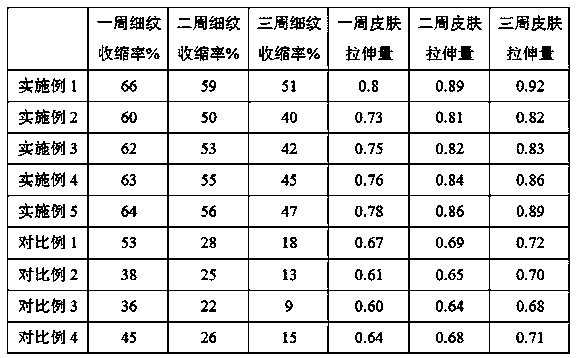

Examples

Embodiment 1

[0035] A nourishing and repairing freeze-dried powder, comprising a freeze-dried powder part and a solvent part, the freeze-dried powder part is made of the following raw materials in parts by weight: 91.67 parts of deionized water, 5 parts of mannitol, 0.9 parts of trehalose, 0.12 parts of Sodium chloride, 0.18 part of disodium hydrogen phosphate, 0.1 part of sodium dihydrogen phosphate, 1 part of blue copper peptide, 1 part of ectoine, 0.03 part of mixed peptide.

[0036] The mixed peptide is composed of palmitoyl tetrapeptide-7, tripeptide-1, hexapeptide-9, palmitoyl pentapeptide-4, palmitoyl tripeptide-1, palmitoyl tripeptide-5, and the palmitoyl tetrapeptide -7. The weight ratio of tripeptide-1, hexapeptide-9, palmitoyl pentapeptide-4, palmitoyl tripeptide-1 and palmitoyl tripeptide-5 is 6:1:1:1:1:1.

[0037] The solvent part is composed of the following raw materials in parts by weight: 98.3 parts of deionized water, 0.05 parts of sodium hyaluronate, 0.05 parts of polygl...

Embodiment 2

[0049] The difference between embodiment 2 and embodiment 1 is that the proportioning of the freeze-dried powder part is different, and the others are the same.

[0050] The freeze-dried powder part is made of the following raw materials in parts by weight: 90 parts of deionized water, 4 parts of mannitol, 0.6 part of trehalose, 0.1 part of sodium chloride, 0.15 part of disodium hydrogen phosphate, 0.05 part of sodium dihydrogen phosphate , 0.5 part of blue copper peptide, 0.8 part of ectoine, 0.02 part of compound peptide.

Embodiment 3

[0052] The difference between embodiment 3 and embodiment 1 is that the proportioning of the freeze-dried powder part is different, and the others are the same.

[0053] The freeze-dried powder part is made of the following raw materials in parts by weight: 95 parts of deionized water, 6 parts of mannitol, 0.12 part of trehalose, 0.15 part of sodium chloride, 0.25 part of disodium hydrogen phosphate, 0.2 part of sodium dihydrogen phosphate , 1.5 parts of blue copper peptide, 1.2 parts of ectoine, 0.04 parts of compound peptide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com