A chassis dynamometer motor frame with torque detection and radial cooling functions

A chassis dynamometer, radial cooling technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as vibration and temperature measurement and control difficulties, abnormal output data of torque detection devices, and restrictions on motor design and application. , to achieve the effect of improving convenience and installation efficiency, reasonable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

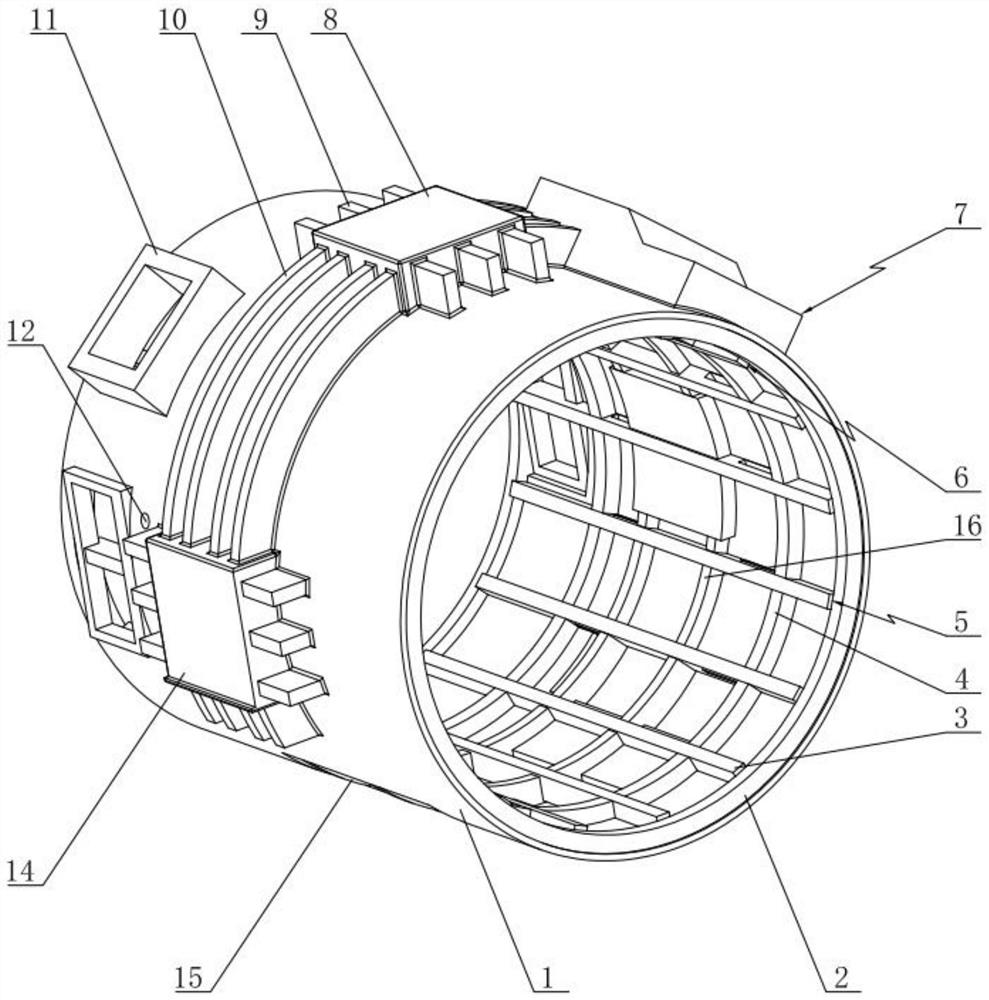

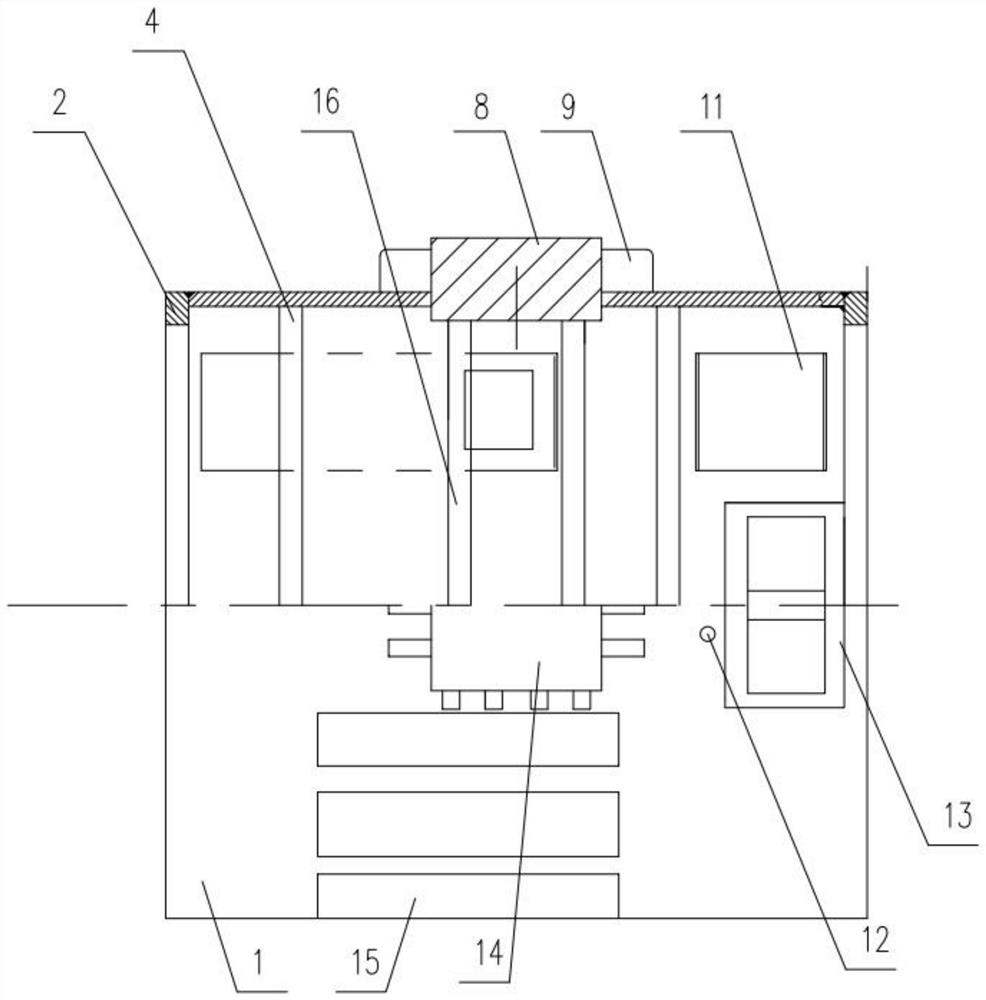

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0033] Such as Figure 1~2 As shown, the present invention includes a coaming plate, and the two side edges of the coaming plate are bent toward each other and abut against each other, so that the coaming plate is closed to form a base body 1, which is a cylindrical hollow body; the middle part of the outer wall of the base body 1 is Several detection platform mounting holes are opened equidistantly, and the vertical detection platform 8 and the horizontal detection platform 14 are respectively arranged in the detection platform mounting holes, and the outer circumference of the vertical detection platform 8 and the horizontal detection platform 14 are also fixedly connected with the outer wall strengthening mechanism, in a group The first air inlet mechanism is arranged between the adjacent detection platform mounting holes, and several a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com