Preparation method of sub-nano platinum-based ordered alloy

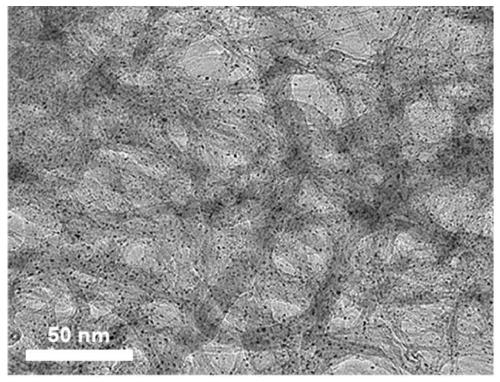

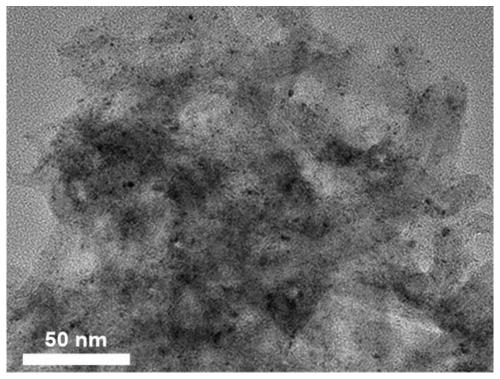

A technology of ordered alloys and platinum-based alloys, applied in the field of chemical materials, can solve the problems of large catalyst particle size and insufficient dispersion, and achieve the effect of simple and easy preparation method, improved catalytic activity, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for preparing a subnano platinum-based ordered alloy, comprising the following steps:

[0053] Step 1: ultrasonically disperse 100mg of multi-walled carbon nanotubes (MWCNT) in 100ml of 1mol / L hydrochloric acid solution, then add 100mg of aniline, and then ultrasonically disperse to obtain a uniformly dispersed mixed solution, place the mixed solution in a low-temperature In the constant temperature reaction bath, add 1ml of 0.04mmol / L FeCl dropwise3 After the solution was continuously stirred for 10 hours, after adding the initiator APS and continuing to stir for 20 hours, it was evaporated to complete dryness at 50°C using a rotary evaporator, and then calcined under an argon atmosphere to obtain FeNC single atoms. The calcining temperature was 900°C. Calcination time is 2h.

[0054] Step 2: ultrasonically disperse the FeNC single atom prepared in step 1 into 100ml of 1mol / L hydrochloric acid solution, and add 1ml of chloroplatinic acid solution dropwise, sti...

Embodiment 2~15

[0057] The preparation methods of Examples 2-15 are the same as those of Example 1, except that, as shown in Table 1, the components and process parameters of non-noble metal precursor solutions and platinum precursors used are different.

[0058] Table 1 is a list of components and process parameters of Examples 2 to 8 ("--" in the table represents unused)

[0059]

[0060]

[0061] Table 2 is a list of components and process parameters of Examples 9 to 15 ("--" in the table represents unused)

[0062]

[0063]

[0064] Enumerate 5 groups of comparative examples and embodiment 1~10 in addition and carry out comparative experiment:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com