High-pressure slide valve type check valve

A high-pressure slide valve and one-way valve technology, applied in the field of one-way hydraulic valves, can solve the problems of increased vibration and noise of the hydraulic system, poor opening speed, and shortened service life, so as to reduce the leakage of hydraulic oil and avoid the flow of hydraulic oil. Empty, fast-moving and smooth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

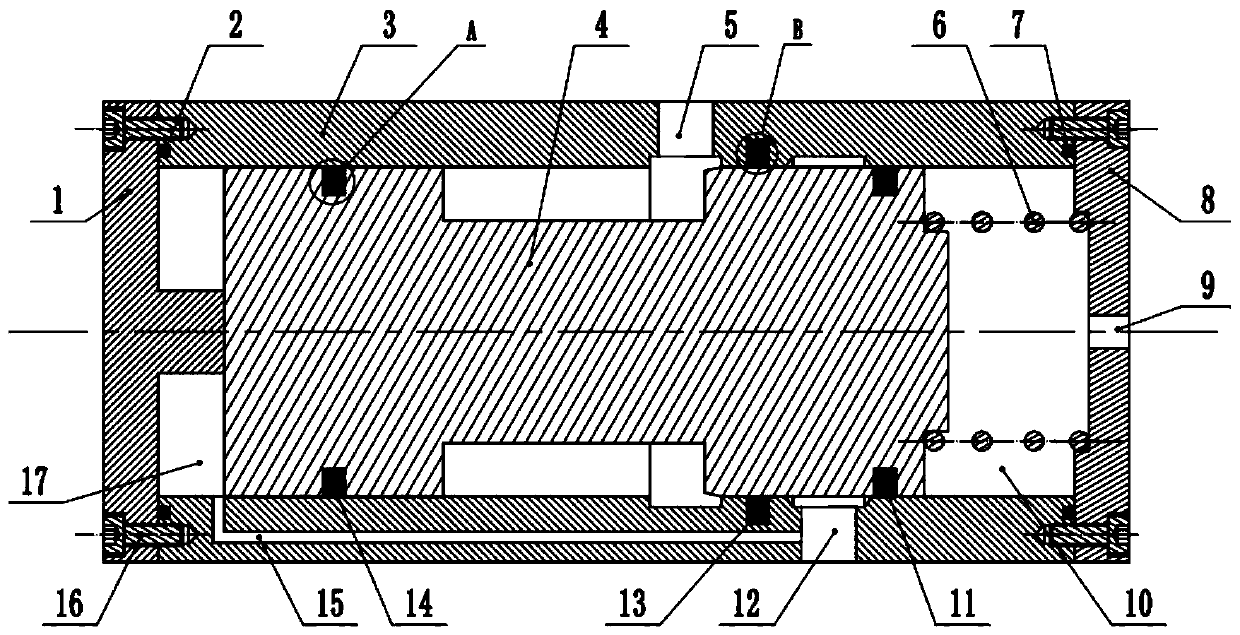

[0052] A high pressure spool type check valve. Such as figure 1 As shown, the high-pressure slide valve check valve includes a valve body 3 , a valve core 4 , a spring 6 , a left valve cover 1 and a right valve cover 8 . The left valve cover 1 and the right valve cover 8 are installed on the corresponding left and right ends of the valve body 3 through bolts 16. The valve body 3 is equipped with a valve core 4 and a spring 6. One end of the spring 6 is in contact with the right valve cover 8, and the spring 6 The other end is in contact with the right end of the spool 4; the right cylindrical surface of the spool 4 is equipped with a first combination sealing ring 11, the middle part of the inner wall of the valve body 3 is equipped with a second combination sealing ring 13 on the right side, and the left side of the spool 4 The third combined sealing ring 14 is installed on the cylindrical surface; the left sealing ring 2 and the right sealing ring 7 are respectively install...

Embodiment 2

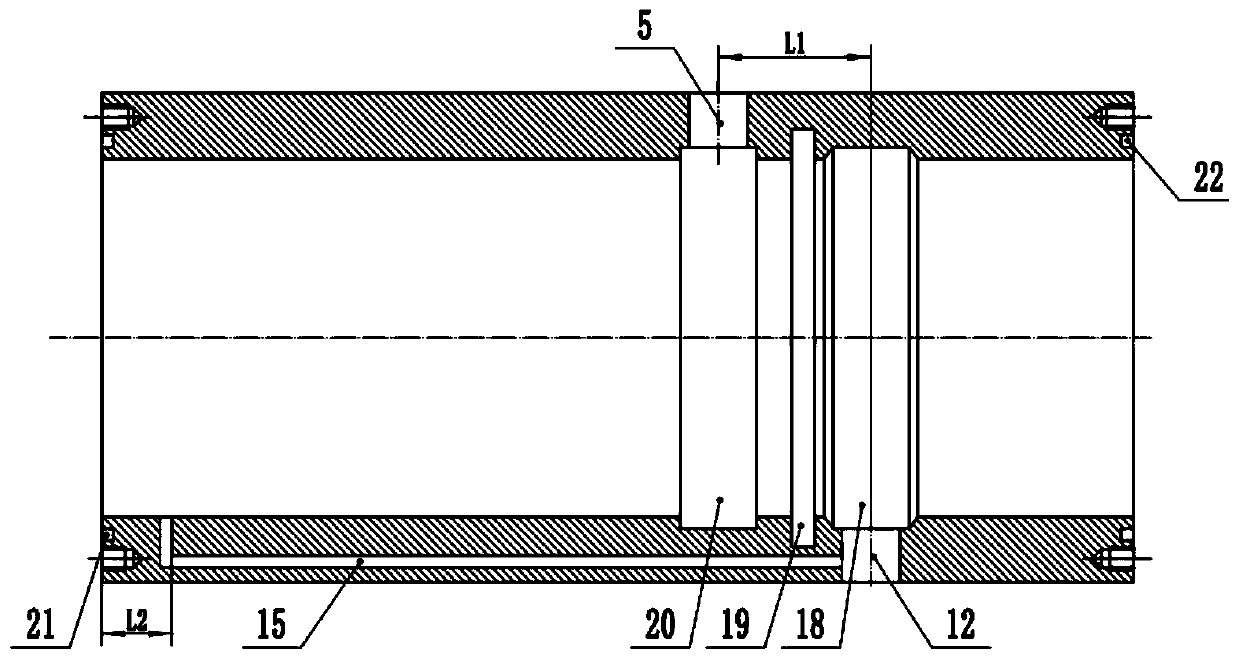

[0064] A high pressure spool type check valve. Except following technical parameter, all the other are with embodiment 1:

[0065] The distance L1 between the extension line of the center line of the first oil port 5 and the extension line of the center line of the second oil port 12 is 30-40mm.

[0066] The included angle between the annular slope and the inner wall is 42-45°

[0067] The distance L2 between the oil outlet of the control oil passage 15 and the left end surface of the valve body 3 = 22-25mm;

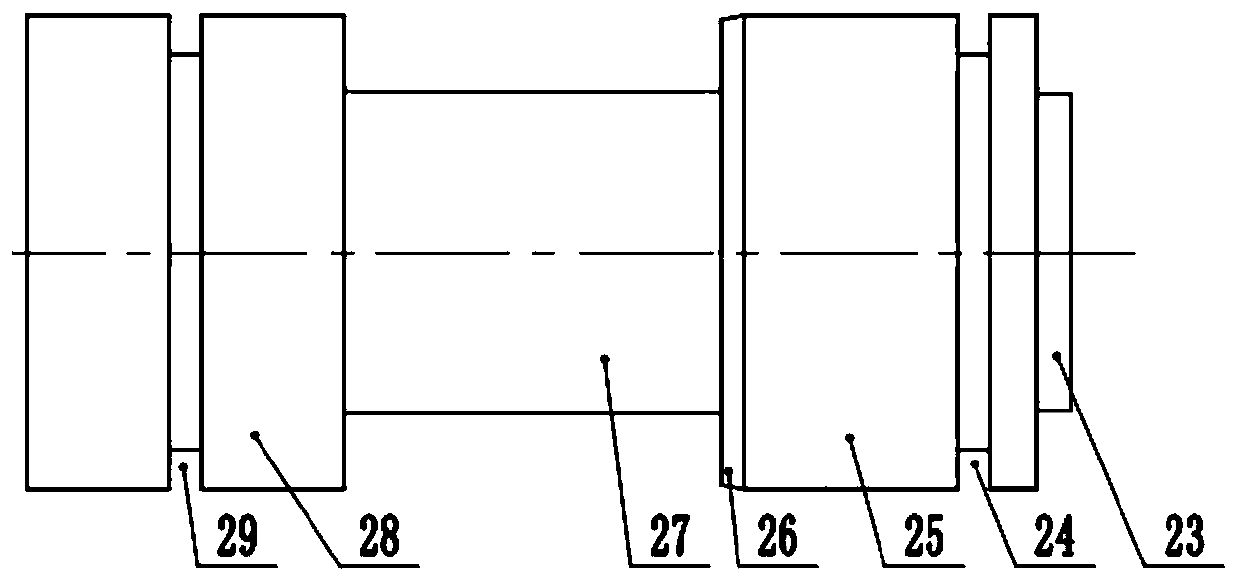

[0068] The gap between the diameter of the left cylinder 28 and the right cylinder 25 of the valve core 4 and the inner wall of the valve body 3 is 7-10 μm.

[0069] The free length of the spring 6 is 55-80 mm, and the compression amount is 30-40 mm.

[0070] Compared with the prior art, this specific embodiment has the following advantages:

[0071] 1. When the high-pressure oil enters from the second oil port 12 and enters the left chamber 17 through the control oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com