Secondary water supply water tank with dead end filtration and self-cleaning functions and secondary water supply method

A secondary water supply and self-cleaning technology, applied in chemical instruments and methods, filtration circuits, water supply devices, etc., can solve problems such as the impact of domestic water safety, poor management, and small working space, so as to improve the self-cleaning effect and ensure Filter effect, enhance the effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

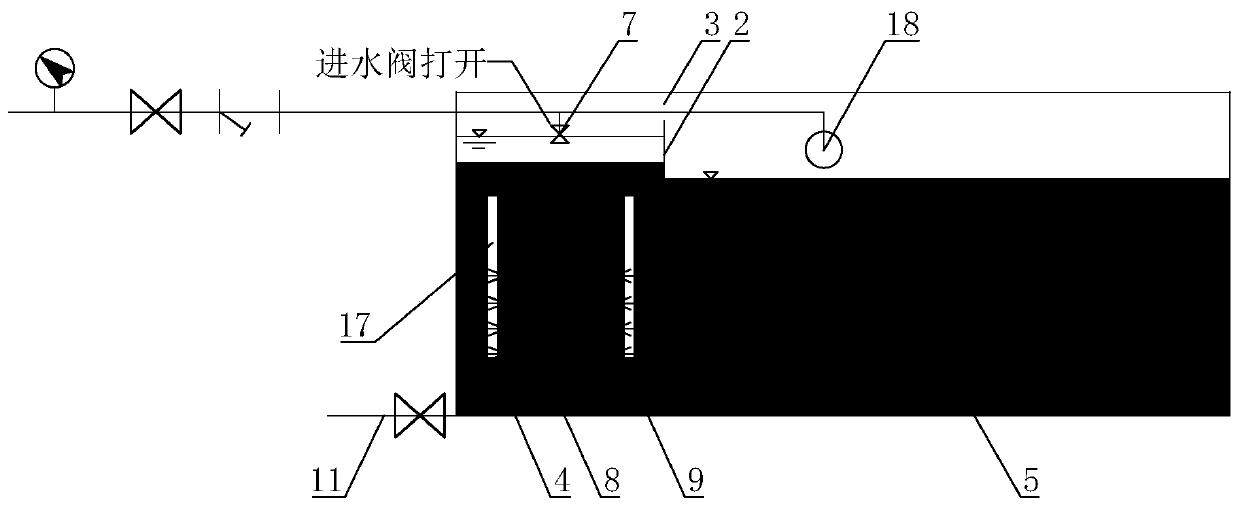

[0035] As shown in the figure, a secondary water supply tank with full filtration and self-cleaning functions includes a water tank body 1, a baffle 2 is vertically arranged inside the water tank body 1, and the top wall of the baffle 2 and the top wall of the water tank body 1 The overflow channel 3 is formed at intervals, the baffle plate 2 divides the water tank body 1 from front to back into the first water tank 4 and the second water tank 5, the first water tank 4 is connected with the municipal water pipeline 6, and the municipal water pipeline 6 enters the first water tank One end of the water tank 4 is provided with a water inlet valve 7, the first water tank 4 is provided with a filter device 8, at least one side of the filter device 8 is provided with a filter water inlet communicating with the outside, and the bottom of the filter device 8 is provided with a filter water outlet. The filtered water outlet communicates with the second water tank 5 through the connectin...

Embodiment 2

[0039] This embodiment proposes a secondary water supply tank with full volume filtering and self-cleaning functions, which further defines the structure of the filtering device 8 on the basis of the first embodiment. In the present embodiment, the side wall of filter device 8 is surrounded by stainless steel metal filter screen 14, and the mesh of stainless steel metal filter screen 14 constitutes filter water inlet, and the top and bottom end of filter device 8 are sealing settings, and filter water outlet 15 is opened At the bottom end of the filter device 8 , several filter medium units 16 are arranged inside the filter device 8 .

[0040] In this embodiment, the fineness of the stainless steel metal filter screen 14 is 100 microns, and in other embodiments, the filter screen fineness range may be 0.1, 10, 50 microns, etc. The filter medium unit 16 is filled with a single or combination of the following filter materials: quartz sand, granular activated carbon, medical ston...

Embodiment 3

[0042] This embodiment proposes a secondary water supply tank with full volume filtration and self-cleaning functions, which further improves the structure inside the first water tank 4 on the basis of the first embodiment. In this embodiment, an ultrasonic vibrating plate 17 is arranged in the first water tank 4 , and the ultrasonic vibrating plate 17 is arranged in parallel on both sides or the outer periphery of the filtering device 8 . Opening the ultrasonic plate vibrating plates on both sides or around the filter device during cleaning can further enhance the cleaning effect of the filter device under the influence of water flow.

[0043] In this embodiment, the first water tank 4 is filled with fiber ball filter material, and the fiber ball filter material is arranged on the outer periphery of the filter device. Therefore, the effect of water flow during the backwashing stage is used to further enhance the cleaning effect by rolling the fiber ball. The fiber ball also h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com