Solid waste and hazardous waste cleaning and recycling treatment method

A disposal method and recycling technology, applied in the field of waste recycling, can solve problems such as high cost, difficulty in cleaning, secondary pollution, etc., achieve the effect of reducing disposal energy consumption and operating costs, and improving resource utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

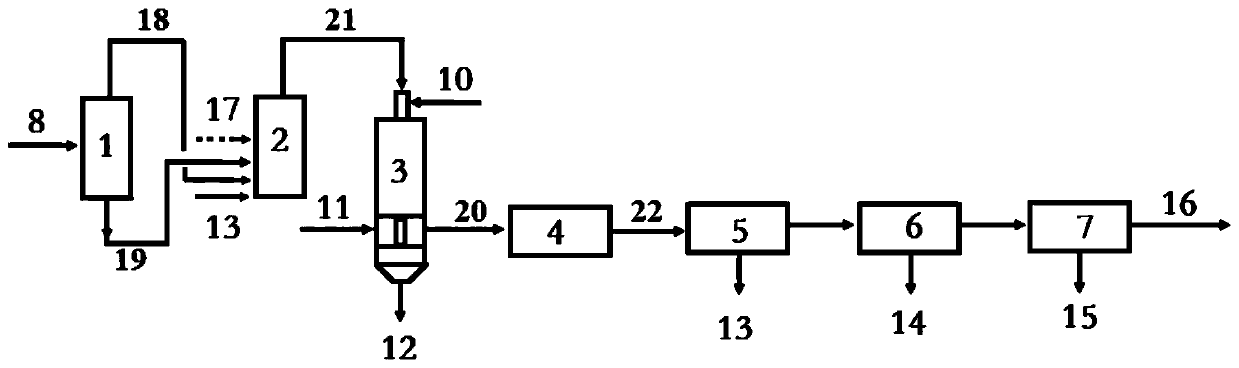

[0078] see figure 1 As shown, the clean resource disposal method of solid waste and hazardous waste of the present invention comprises the following steps:

[0079] (1) The waste 8 is sent into the pyrolysis furnace 1, and during the heating process, the pyrolysis gas 18 generated by thermochemical reactions such as distillation and cracking of the organic matter in the waste 8 leaves from the gas phase outlet at the top of the pyrolysis furnace 1, The ash, heavy metals, coke produced by pyrolysis and solid residues that have not been pyrolyzed become pyrolysis residues 19 and are discharged from the slag outlet at the bottom of the pyrolysis furnace 1 .

[0080] (2) The pyrolysis gas 18 and pyrolysis residue 19 discharged from the pyrolysis furnace and the selectively added high-calorific value substances 17 enter the gas-solid pressurized conveying device 2 for pressurized and mixed treatment to obtain a multi-phase material 21, a multi-phase material 21 Enter the high-temper...

Embodiment 1-1

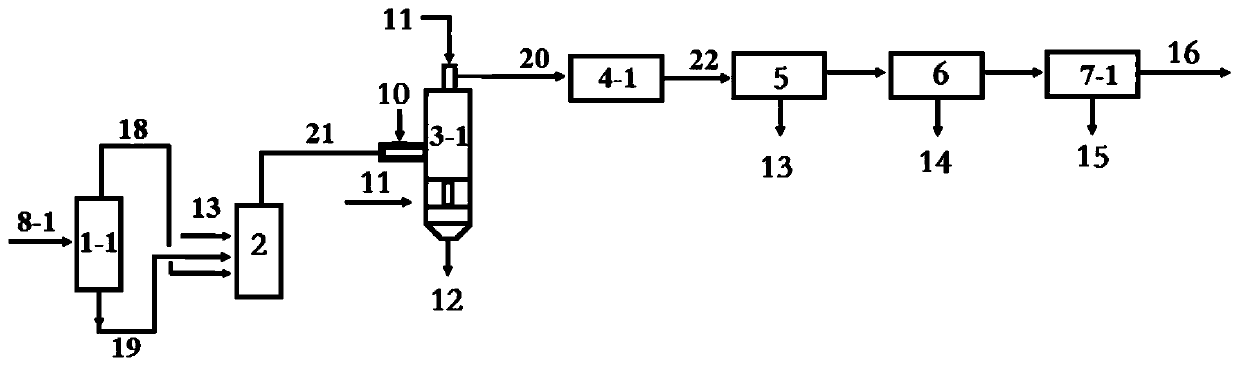

[0087] see figure 2 with Figure 13 As shown, the clean resource disposal method of solid waste and hazardous waste of the present invention comprises the following steps:

[0088] (1) After the municipal solid waste 8-1 is drained, it is crushed by a double-roller crusher and then sent to the rotary pyrolysis furnace 1-1 by a belt. ℃ (the heat source partly comes from the heat carried by the gas medium nitrogen of the gas-gas heat exchanger 4-1, and partly comes from the combustion of clean coal gas); in the rotary pyrolysis furnace 1-1, the domestic garbage 8-1 is dried, carbonized, Thermochemical reactions such as pyrolysis; about 350Nm is discharged from the exhaust port of the rotary pyrolysis furnace 1-1 3 / (t garbage), calorific value is 4000Kcal / Nm 3 The left and right pyrolysis gas 18 entrained with tar is discharged from the lower slag outlet of the rotary pyrolysis furnace 1-1 and is composed of ash content, heavy metals, coke and other substances produced by cr...

Embodiment approach 2

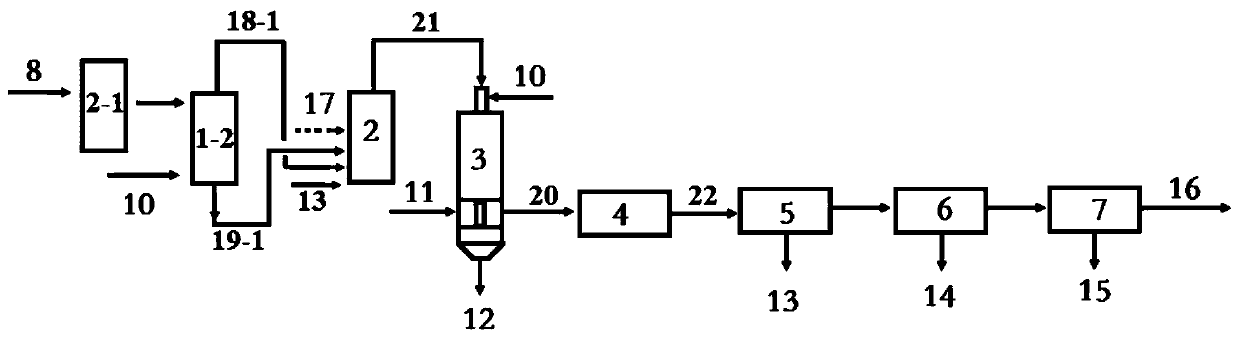

[0101] see image 3 As shown, waste 8 is sent to low-temperature gasification furnace 1-2 by solid pressurized conveying device 2-1 after being processed, and in low-temperature gasification furnace 1-2, add by water vapor and oxygen-containing oxidizing agent (air, The gasification agent 10 composed of oxygen-enriched air or oxygen) is subjected to low-temperature gasification reaction to produce crude gas 18-1, and the crude gas 18-1 is discharged from the gas phase outlet of the low-temperature gasification furnace 1-2, and the organic solid waste and hazardous waste The ash, heavy metals and organic solid wastes that have not been gasified become gasification slag 19-1 and are discharged from the slag outlet of low-temperature gasification furnace 1-2. Gasification slag 19-1 and selectively added high-calorific value substances 17 The solid pressurized conveying device 2 is mixed with the raw coal gas 18-1 from the low-temperature gasification furnace 1-2 and sent to the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com